Due to their low weight the use of lightweight aluminum alloys for car body components is being pushed in order to improve energy efficiency. Since aluminum alloys exhibit significantly higher formability at low (cryogenic) temperatures (down to -180°C) than at room temperature (cryo-effect), experts at the LKR have developed a new process for forming aluminum sheets in the "KryoAlu" project series. The improved property profile thus opens up new applications for aluminum in the automotive industry.

The state of the art is to form aluminum at elevated temperatures, as sheets are soft and thus high plastic elongations are possible. However, the transferable forming force is also lower, which can lead to cracks in the formed component. Heating causes a change in the microstructure and the final component loses its strength required for the application. Energy-intensive, additional heat treatment processes are necessary.

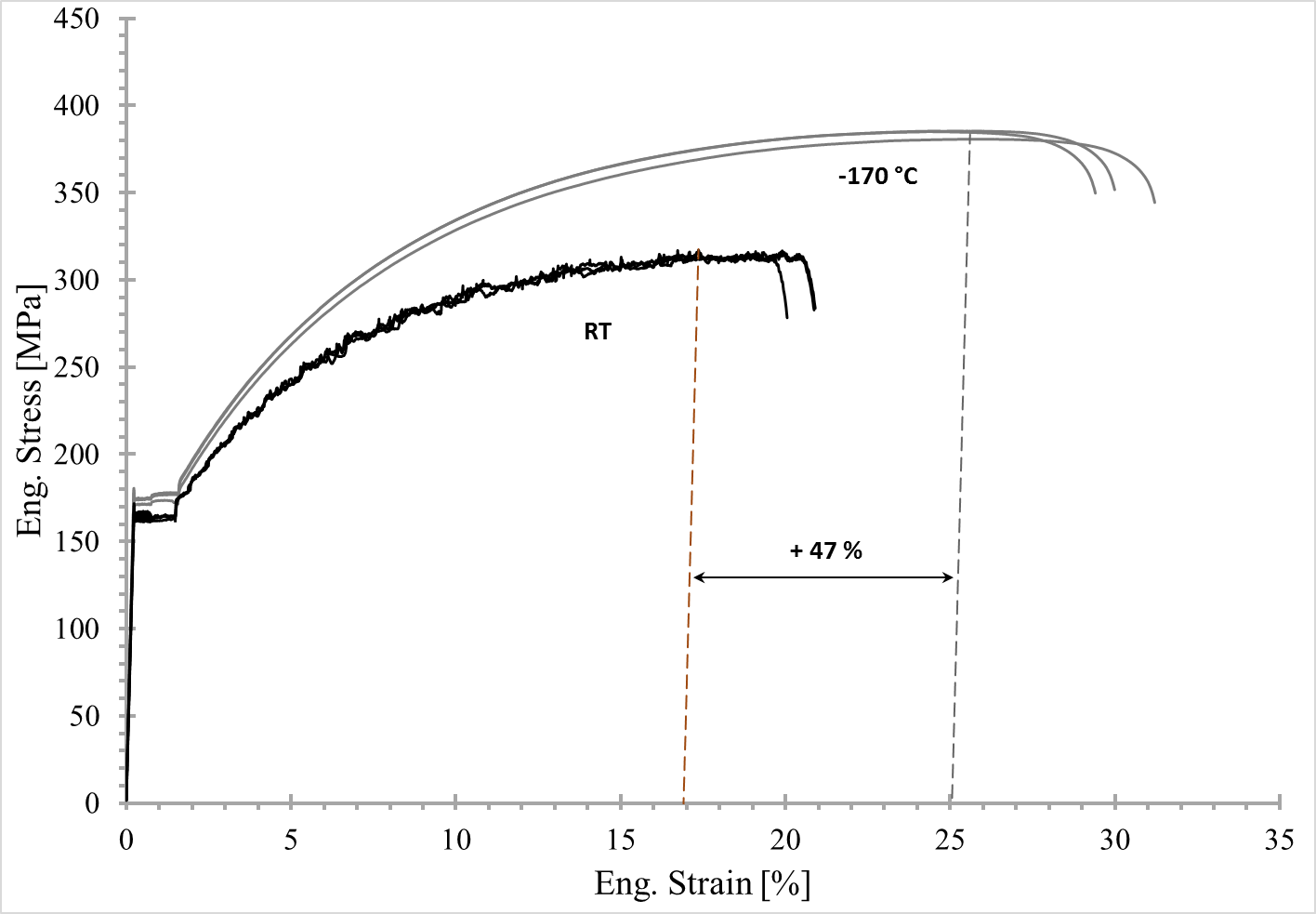

Central to the phenomenology of the cryogenic effect is that even at low temperatures the plastic strain improves compared to room temperature, as demonstrated by tensile tests in Fig.1. The microstructure remains unchanged, however, unlike at high temperatures. Thus: the colder, the better the mechanical properties.

Fig.1: Increase in stress and strain in tensile test at -170°C compared to room temperature

In addition to the increase in plastic strain, there is also an increase in fracture toughness and strength at cryogenic temperatures, with the higher strain hardening also leading to more uniform forming. Flow lines, occurring e.g. due to the Portevin-Le Chatelier (PLC) effect, are greatly reduced by cryogenic temperatures - an essential criterion for industrial implementation.

Methodically, the cryogenic effect was first demonstrated at the LKR in uniaxial tensile tests (Fig.1) and subsequently confirmed by multi-axial stress-strain loading such as Erichsen-tests or in the plane strain state by notch tensile tests at up to -196°C. Finally, the findings were transferred to a cryogenic forming process of a miniaturized B-pillar and its semi-industrial suitability was demonstrated

Fig.2: Proof of suitability for small series production on a miniaturized B-pillar

LKR's forming experts developed a process in which aluminum sheets of the 5xxx and 6xxx series are precooled in liquid nitrogen (minus 196°C), inserted by a robot into forming tools cooled to minus 180°C and removed again after deep drawing. In this way, geometrically complex parts can be produced from a single piece of sheet metal. This eliminates the need for joints, and a high surface quality can also be achieved. Depending on the specific application, these advantages can compensate for the increased costs due to cooling.

Property improvements through cryogenic forming

- Better formability

- Better surface

- Lower cracking tendency

- No additional heat treatments necessary

- Higher component strength (compared to hot formed components)

- Higher crash resistance

![[Translate to English:] LKR Standort](/fileadmin/_processed_/1/f/csm_AIT_LKR_Standort_4fe61c1df0.jpg)