The research area "Solid State Batteries" deals with a highly promising technology. Solid state batteries do not contain liquid electrolytes (which are flammable) and are thus safer and more durable. A number of suitable materials are already known – such as polymers, ceramics and glasses, or sulfide-based substances – each of which has specific advantages and disadvantages. Corresponding manufacturing methods for solid-state batteries are now being developed in a new solid-state battery lab at AIT.

Objectives

- Establishing a manufacturing baseline for state-of-the-art solid-state battery materials

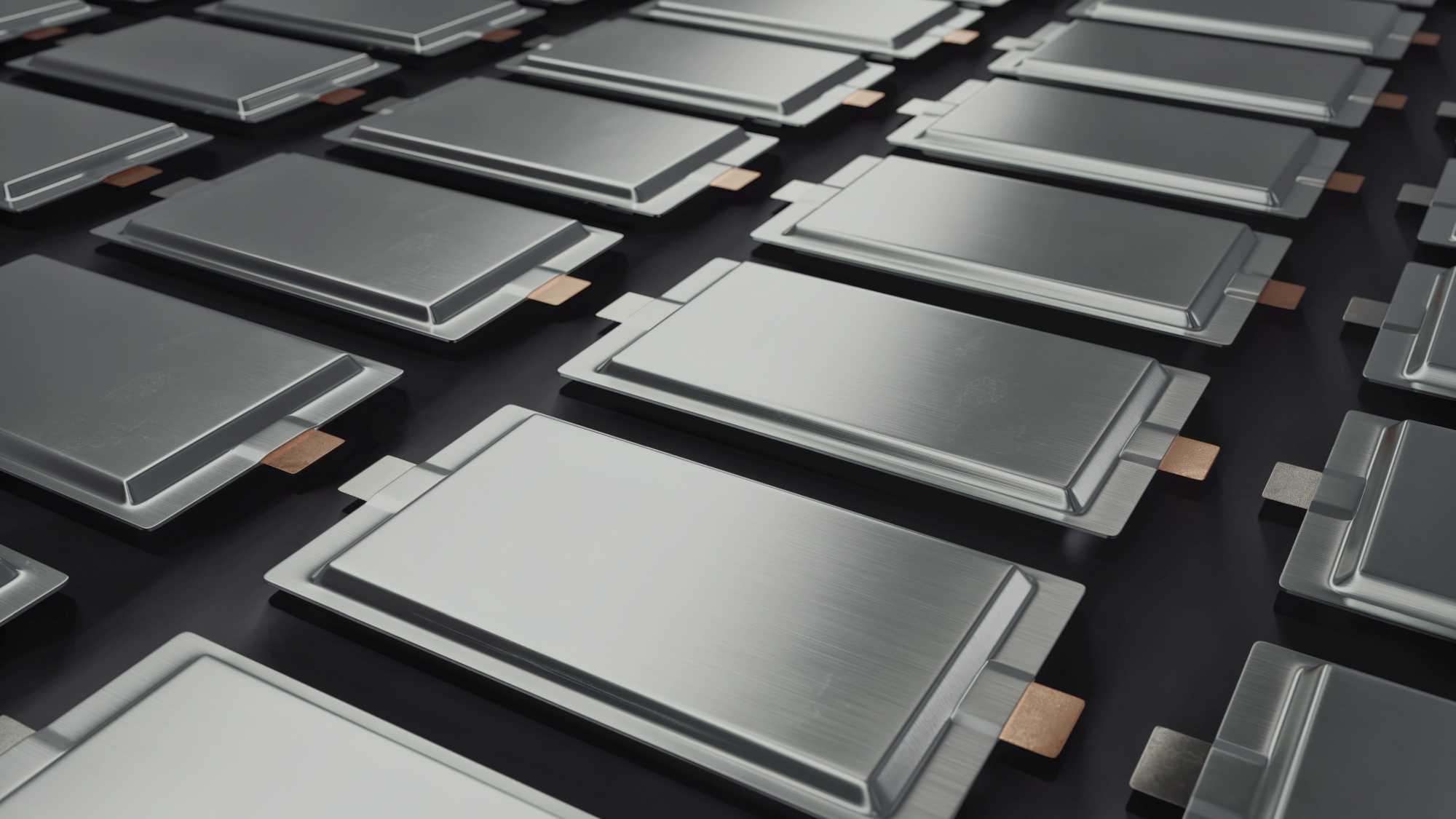

- Enabling hybrid polymer-ceramic based pouch cell manufacturing of 1+Ah cells

- Reduction of unwanted metallic Li formation on the anode side

- Interface stabilization of NMC vs. polymer hybrid electrolytes

In detail the challenges of solid-state battery technologies that we are tackling can be summarised as:

- Interface stability of solid electrolytes with Li and anodeless configurations. The majority of solid electrolytes either exhibits a low compatibility with Li metal at the anode or cannot prevent sufficiently the growth of Li dendrites. Protection layers between the electrolyte and anode are required to ensure electrochemical stability as well as safety of the cell.

- Interface stability of solid electrolytes with composite cathodes above 4V cell voltage. Solid electrolytes, especially those with good ionic conductivity, exhibit typically a low electrochemical stability window, leading to fast degradation above 4V. This is the main reason why Lithium-Iron-Phosphate (LFP) has been used as cathode material in other studies, but using cathode materials of generation 3b (e.g., Nickel Manganese Cobalt oxide NMC) is necessary to achieve the desired energy density targets.

- Reproducible processing of cell components into multi-layer pouch cells. Apart from electrochemical compatibility of the cell components, their integration into a pouch cell is equally challenging as the physical interface connection between layers has a big impact on cell performance. Furthermore, no industrial standard processes have been established for cell assembly, which is a major focus of production research.