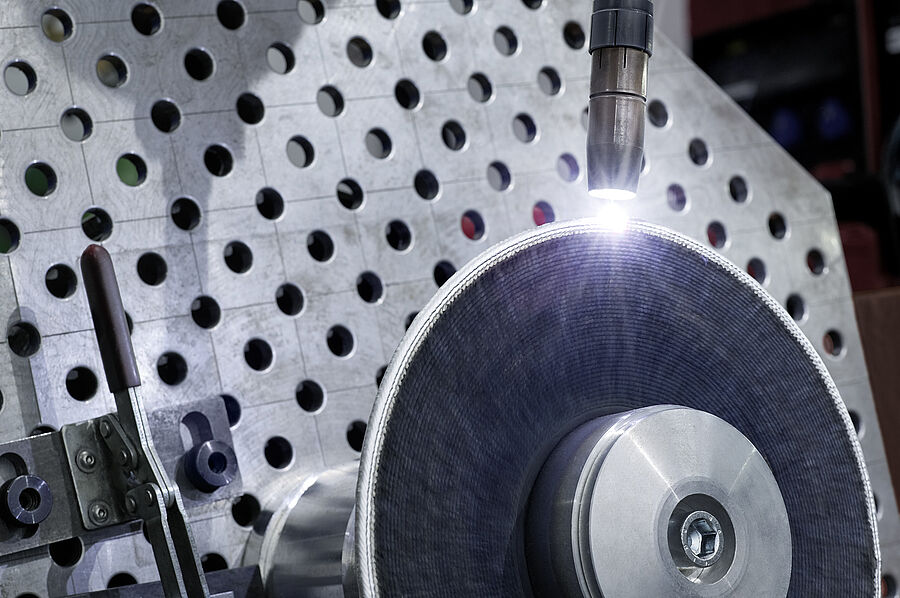

Common welding technologies are used at LKR

- MIG/MAG,

- CMT (CMT Advanced and CMT TWIN)

- TIG (with one and two wires) and

- Plasma arc welding

The equipment technology makes it possible to weld all materials equally. At the LKR we have special know-how for the processing of light metal alloys. Our welding laboratory can be adjusted to every welding position as well as temperature or environmental condition. Particularly demanding welds require precisely coordinated temperature control and stable process characteristics. Therefore, our well-equipped laboratory contains several component heaters, a high-speed camera for process monitoring and other enhancements.

The LKR is ideally equipped for unusual welding or brazing tasks, such as the use of special welding or brazing additives, the achievement of the highest quality or even complex welding torch guidance. The welding robot programming is created and optimized offline using a CAD drawing and software specially adapted to robots. In order to be able to produce welds of the best quality, close inspection in our in-house laboratory is an essential. The accredited testing laboratory has all the necessary methods available to determine the desired properties for materials characterization.

Many welding and brazing processes require additives as wires and rods. Besides off-the-shelf materials it is also possible to test special materials. For this purpose, the LKR can produce special wires in small quantities, if necessary. This allows testing of new material combinations or new additives at reasonable cost. The special challenge is the wide-ranging know-how that is necessary along the process chain.

The advantages of the process are

- No tonnages of material must be produced to conduct initial tests.

- The wires can be tested at an early stage, thus avoiding the influence of ageing effects.

- A flexible adjustment of the chemical composition is possible.

- New materials can be tested economically.

The LKR also uses the same technology to produce materials for brazing. Solders can be produced as wires, rods or powder. It is also possible to produce solders directly as a layer on a base material. The manufactured solders can be tested directly in our joining laboratory.

Our main mission at the LKR is a complete and comprehensive mapping of the welding or soldering task from the idea to the first component.

![[Translate to English:] LKR Standort](/fileadmin/_processed_/1/f/csm_AIT_LKR_Standort_4fe61c1df0.jpg)