The goal of “LIANDRI – Advancing time-of-flight technology for high performance light detection and ranging” is to bridge innovative yet application-driven research on photonic sensing with near-future exploitation in the fields of automated driving and industrial manufacturing. On the medium term LIANDRI’s finding will enable cars to recognize and identify distant yet small obstacles along road infrastructures, while robots of future factories will be able to perform manufacturing task that require precise alignment and tooling procedures more efficiently.

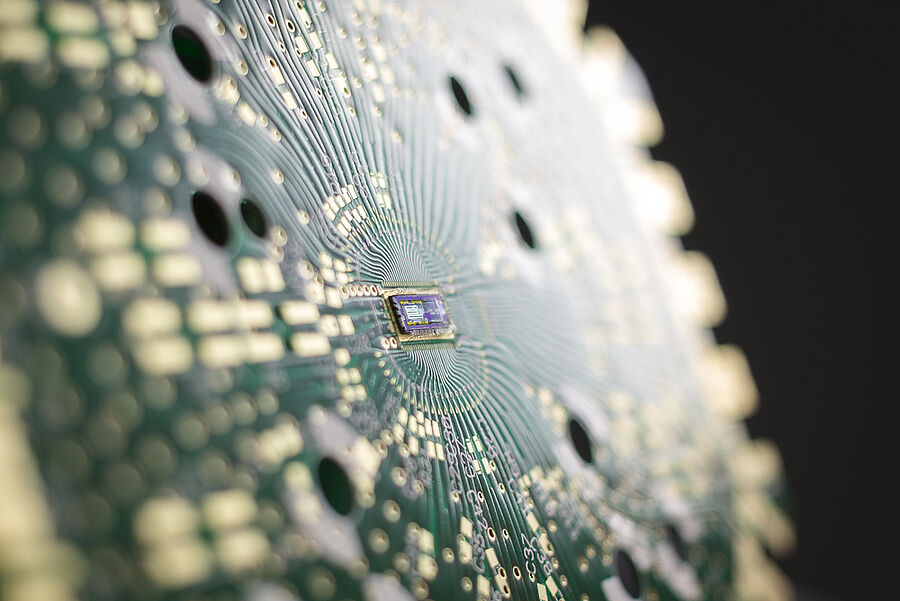

By introducing photonics – a key enabling technology recognized through its leaps in performance beyond that found in the state-of-the-art, sensor systems are particularly brought forward in terms of range and resolution. The so-called LIDAR technology, which stands for light-based detection and ranging, will exploit time-of-flight measurements, in which a short light pulse is emitted and the round-trip time of its reflection at a remote target is measured. Together with an electronic beam-steering mechanism a 3D image of the scene is yielded in short time, enhancing reliability and reducing size compared to traditional mechanical scanning approaches.

The advantages of LIDAR technology with respect to its radar counterpart are manifold. In case of automated driving the “digital horizon” will be enriched through a seamless acquisition of objects over a range exceeding 200 meters. The simultaneous provision of a high resolution will enable the identification of objects along the traffic infrastructure and will extend the skills of future driver assistance systems which could contribute to the wide adoption of autonomous driving.

For the application in industrial manufacturing environments the situation looks totally different and yet LIDAR will be key: being able to precisely locate objects and tools in a millimeter range in virtue of the high resolution that photonic sensing offers, a higher degree of automation can be achieved, thus raising the overall efficiency of fabrication plants.

LIANDRI as a 3-years project includes 4 partners from Austria and Germany to address its multi-disciplinary research agenda that targets innovations in photonics, microelectronics and signal processing and is jointly funded by the Austrian Research Promotion Agency (FFG), the Association of German Engineers (VDI) and the European Commission within the ERA-NET Co-Fund. Research partners AIT and University of Siegen will tightly work together with innovative industrial partners ams AG and Soft2Tec, which

Facts

- Project start: April 2018

- Project duration: 3 Years

- Funding: funded by the FFG

- Coordination: AIT Austrian Institute of Technology

- Partner: 4 partners from Austria and Germany