The similarities between an autonomous excavator or forklift and the miniaturised 3D surface scanner TinyScan360°, developed by scientists at the Assistive & Autonomous Systems Research Group / AIT Center for Vision, Automation & Control (AAS), may not be immediately obvious. But if you look behind the scenes, both are based on the same approach to capturing the environment.

In the autonomous vehicle, 3D sensors and algorithms capture the environment and the objects in it, locate and classify them to avoid collisions, and perform their tasks reliably - even in difficult weather conditions or when the sensors are contaminated by dust, rain or snow.

Non-contact 3D measurement of ear canals and small boreholes

Miniaturised, these technologies can be used for a wide range of applications. In the medical field, for example, the Dentalscanner - also developed by the research group AAS - creates accurate virtual models of teeth, replacing the previously uncomfortable silicone impressions, while the TinyScan360° for measuring ear canals has already been successfully tested and enables easy and individual fitting of modern hearing aids.

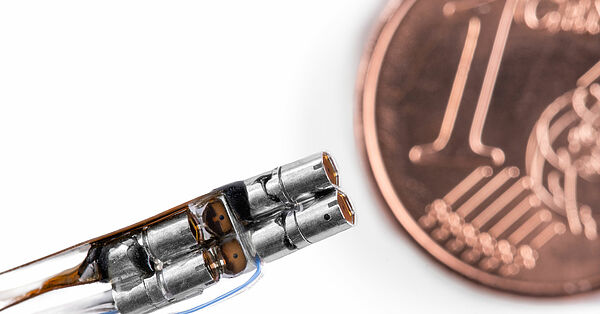

In industrial manufacturing for non-contact quality control, the high-performance stereoscopic 3D measuring system with a design diameter of 3 mm is particularly suitable for measuring, visualising and modelling (3D reconstruction) the smallest objects such as pipes and drill holes with a diameter of less than 10 mm.

Measuring where other sensors cannot reach

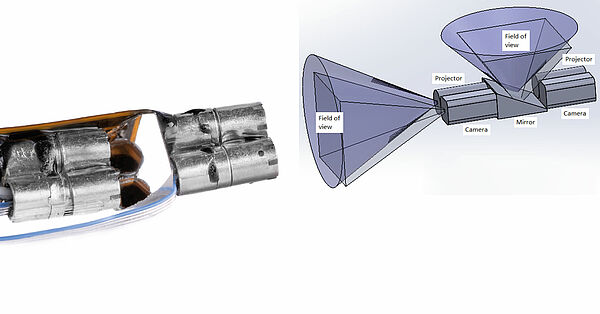

The revolutionary TinyScan 3D surface scanner consists of a camera and a projector with a static light pattern projection that is specially adapted to the 3D measurement application. The projected light pattern makes it possible to capture images even of weakly textured or non-textured surfaces.

Its modular design makes it easy to combine multiple sensor heads, e.g. for simultaneous measurement in different viewing directions. For hand-held use, TinyScan360° is complemented by a so-called orienting camera system - looking outside the area to be measured - to ensure the highest measuring accuracy. All systems are precisely calibrated to each other and contribute to an accurate and comprehensive 3D model. With TinyScan360° it is possible to perform hand-held 3D surface measurements at a measurement distance of between 3 mm and 10 mm from the surface of the object.

TinyScan360° stands out for its unique miniaturised scanner size and precise 3D modelling capability. The scanner is small enough to inspect where other sensors cannot reach. This makes it ideal for 3D measurement of objects and cavities (e.g. bores and internal threads) that have previously been a problem for non-contact measurement systems due to their minimal size, position, geometry and surface properties.

For more information please check

Competence Unit Assistive & Autonomous Systems

Contact

Mag. Monika Riedl-Riedenstein

Assistive & Autonomous Systems

Center for Vision, Automation & Control

AIT Austrian Institute of Technology GmbH

Giefinggasse 4 | 1210 Wien | Österreich

M +43 664 88390027

monika.riedl-riedenstein(at)ait.ac.at | ait.ac.at/aas