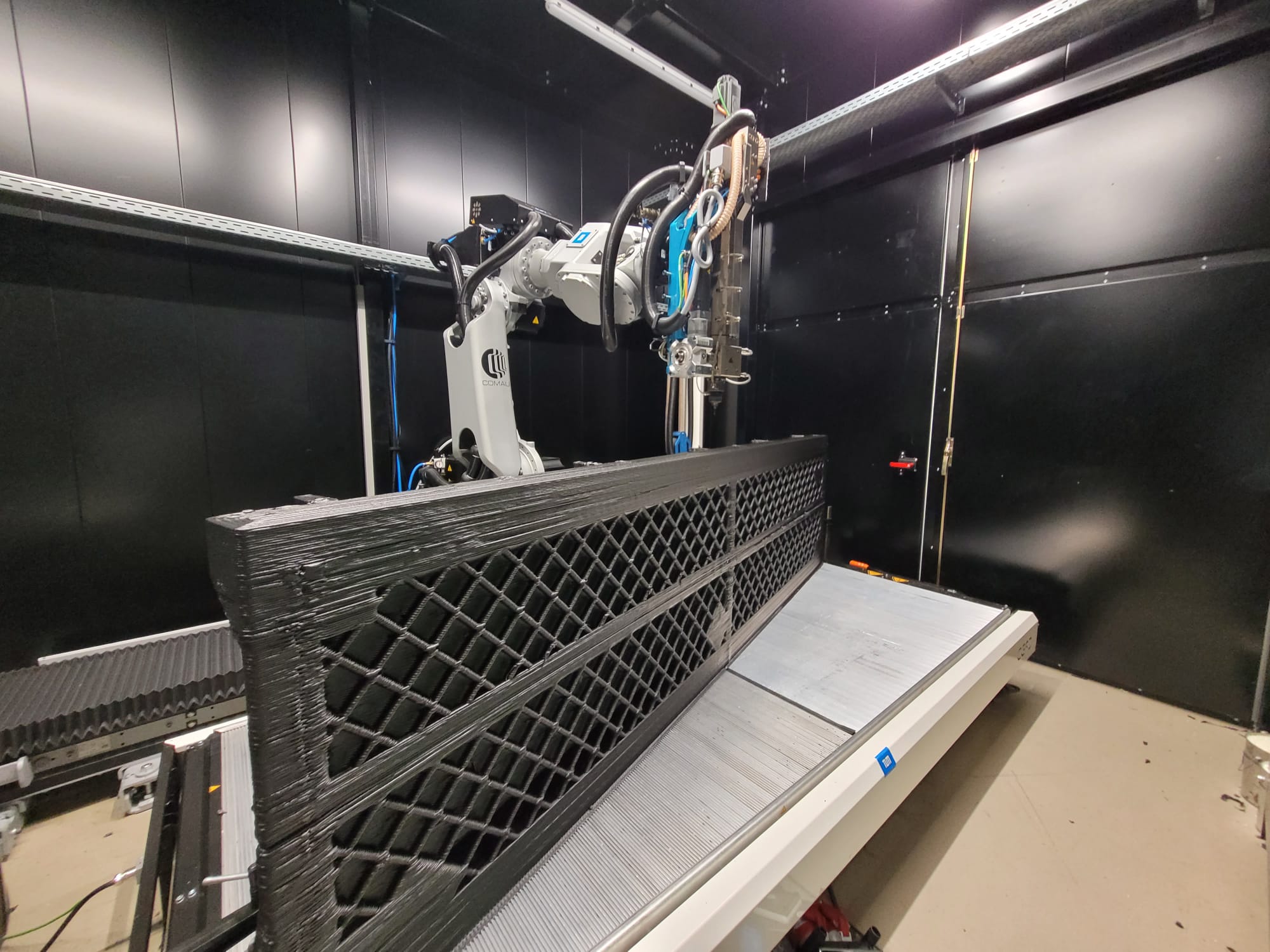

Fig.1: 3D-printed CFRP mono-block, © Lehrstuhl für Carbon Composites, TUM

COMBO3D (COmposite Mould Tool Based On 3D Printing) is a European joint project that demonstrates the possibility of 3D-printing an advanced thermoplastic composite molding tool using additive manufacturing. Fabricated by its project coordinator, Chair of Carbon Composites of Technical University of Munich, these 3D-printed advanced tools will be further used as resin transfer mold (RTM) tools for the production of modern aviation parts, such as carbon fiber/epoxy flaperon wings or aircraft fuselage.

The major challenge of RTM molding tools lies in their thermal performance, for which a temperature homogeneity should be achieved. The anisotropic thermal conductive material, high-performance thermoplastic polyaryletherketone (PAEK), is supplied by one of the project partners Victrex, and it entitles the selection of preferential heat transfer direction. Our focus in this collaboration is on the optimal cooling channel design.

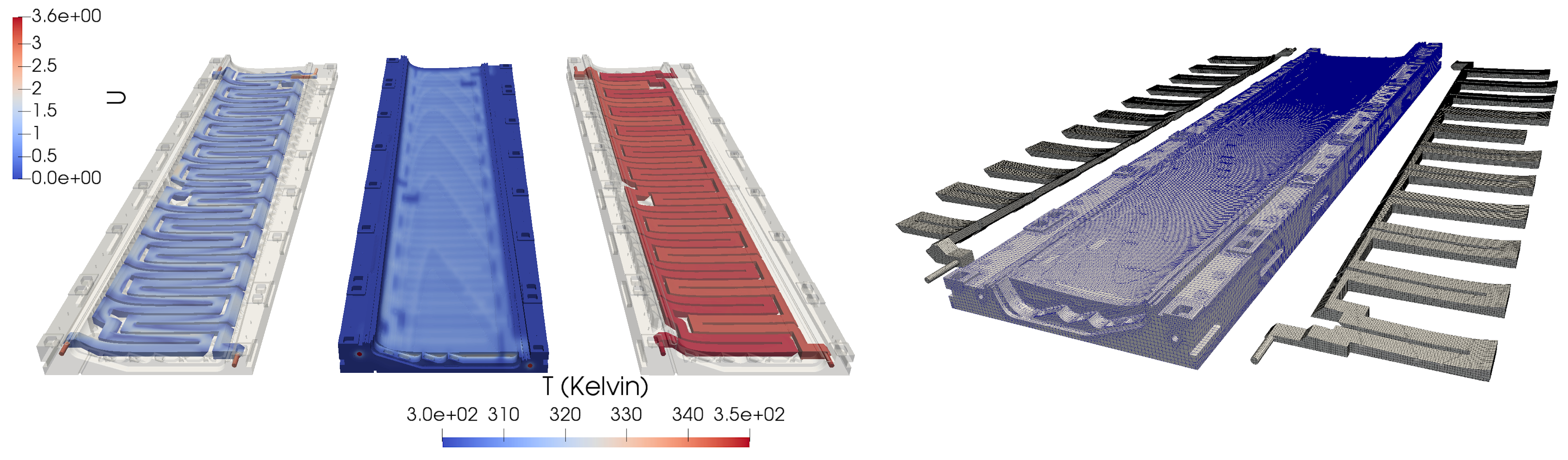

Fig.2: Simulated thermal performance using LKR proposed counter-flow channel pair

As result, the world largest CFRP mono-block was 3D-printed as an RTM tool (fig.1) which uses LKR proposed counter-flow channels. To achieve a more homogeneous surface temperature distribution on the mold surface, the embedded counter-flow channel pair can compensate the temperature gradient that would be generated by the conventional one-directional single channel. Its thermal performance is numerically verified by our conjugate heat transfer simulations (fig.2), which show excellent temperature distribution on the mold surface, both spatially and temporally. This counter-flow design minimizes potential production defects and provides a versatile designing principle for guarantee the temperature homogeneity in the RTM method.

This project has received funding from the Clean Sky 2 Joint Undertaking under the European Union’s Horizon 2020 research and innovation programme under grant agreement No 831989.