Optimisation of plant operation and use of more efficient equipment enable reduction of CO2 emissions by 15%

Optimizing energy consumption and the resulting reduction of greenhouse gas emissions from industrial production processes are key factors in achieving climate targets. Together with the pharmaceutical company Takeda, the AIT Austrian Institute of Technology Center for Energy developed a decarbonization concept for the production site in Vienna. The initial set of identified measures revealed a savings potential of 15 percent or around 600 tons of CO2 per year. Additionally, a path to complete decarbonization was developed and shows as best practice the enormous potential that the use of new technologies such as high-temperature heat pumps coupled with efficiency measures can offer. The high temperature heat pump uses the waste heat from the production process as a source, which has so far been released unused into the environment. The catalogue of measures and the decarbonization concept were developed mainly online in the period from April to October 2020 due to the general COVID-19 situation.

„Our sense of responsibility for the future of our planet is an integral part of our corporate philosophy and a deeply embedded mindset at Takeda. We have set ourselves the goal of becoming CO2 neutral by 2040. By focusing on sustainable solutions and innovations, we massively reduce our CO2 emissions along the entire pharmaceutical value chain“, states Carlos Friedrich, Head of Utilities Engineering of the Takeda production site in Vienna.

„The successful collaboration with Takeda shows that the technologies and methods we develop in the research area of industrial energy systems can be directly applied to industrial processes in the pharmaceutical production. The best practice project with the Takeda production site in Vienna is a win-win for the company and the climate - it brings higher energy efficiency and lower CO2 emissions. For a complete decarbonization of industrial operations like Takeda, the use of industrial heat pumps is an essential building block for a future and efficient energy system“, explains Wolfgang Hribernik, Head of Center for Energy at the AIT Austrian Institute of Technology.

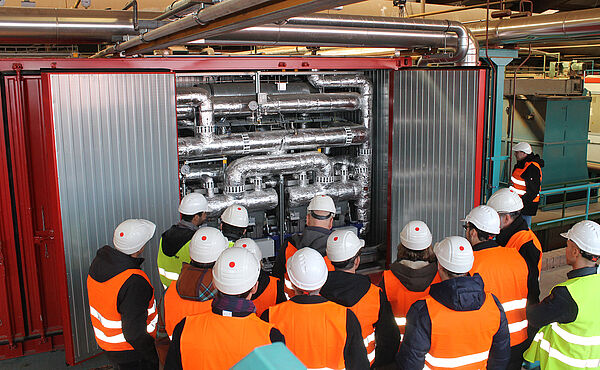

New Heat Pump Technology for pharmaceutical production processes

After evaluating the production processes, the energy sources used and the possible efficiency measures, the AIT Center for Energy drew up a decarbonisation concept for the Vienna site of the pharmaceutical company Takeda. In the processing of blood plasma for the production of vital therapies for people with rare and complex diseases, large amounts of steam are required in particular for cleaning processes and cold is required for cooling and air conditioning processes.

Steam generation in particular requires large quantities of fossil gas, the generation efficiency of which could be increased and the steam requirement reduced by simple measures. For complete decarbonisation, an integration concept of a steam-generating high-temperature heat pump in combination with other units is now under consideration. "Heat pumps are a real alternative to current technologies, especially for low-pressure steam generation from waste heat," explains Gerwin Drexler-Schmid, project manager and Senior Research Engineer at the Center for Energy of the AIT Austrian Institute of Technology.

Global warming requires an optimisation of industrial processes

Following this approach, the project team analyzed the potential of industrial heat between 30°C and 80°C and how it can be sustainably reused, thereby reducing harmful CO2 emissions. With sophisticated waste heat concepts and the use of heat pumps, this waste heat can be made usable and even steam can be generated. This greatly increases energy efficiency compared to conventional gas boilers and massively reduces CO2 emissions.

High-temperature heat pumps are one of the core technologies of the AIT portfolio. In addition, AIT has comprehensive know-how and knowledge in the field of thermal and electrical storage technologies, and, together with partners, covers a broad technology portfolio to create sustainable and, above all, cost-efficient decarbonisation paths. The methods and concepts will be tested together with partners in various industrial sectors like pulp & paper, food and beverages, textiles and chemical industries and will be implemented in existing industrial plants.

About Takeda in Austria: In Austria Takeda works along the entire pharmaceutical value chain: research & development, plasma application, production and distribution. Takeda is Austria's largest pharmaceutical employer and thus an important player in the domestic pharmaceutical industry. Every day, around 4,500 employees help to ensure that medicines from Austria reach the whole world and that patients in Austria have access to innovative medicines from Takeda. Takeda's production sites in Austria are located in Vienna, Linz and Orth an der Donau. The product portfolio helps Austrian patients in the fields of oncology, gastroenterology, immunology, hemophilia and genetic diseases, among others. In 2020, Takeda Austria was recognized as a Top Employer and Great Place to Work. You can find further information on Takeda’s sustainability goals and projects at https://www.ots.at/presseaussendung/OTS_20201130_OTS0146/gruene-und-innovative-arzneimittel-kein-widerspruch

Press Contact AIT:

Mag. Margit Özelt, Marketing and Communications, Center for Energy

T +43 (0)50550-6302 E: margit.oezelt(at)ait.ac.at

Press Contact Takeda:

Astrid Kindler, MA Communications

T: +43 1/20 100-0 E: astrid.kindler(at)takeda.com I https://www.takeda.at