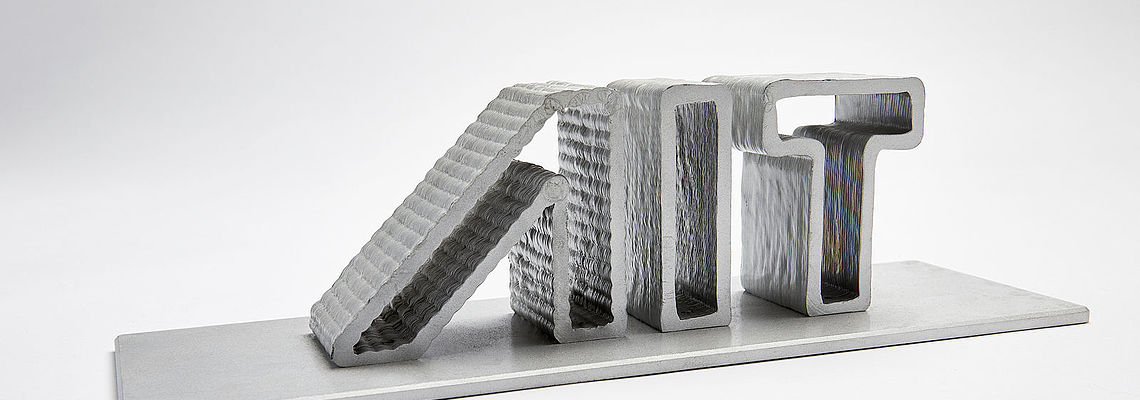

Wire Arc Additive Manufacturing (WAM)

WAM aluminium body and schematic illustration of possible positions for the extraction of tensile samples

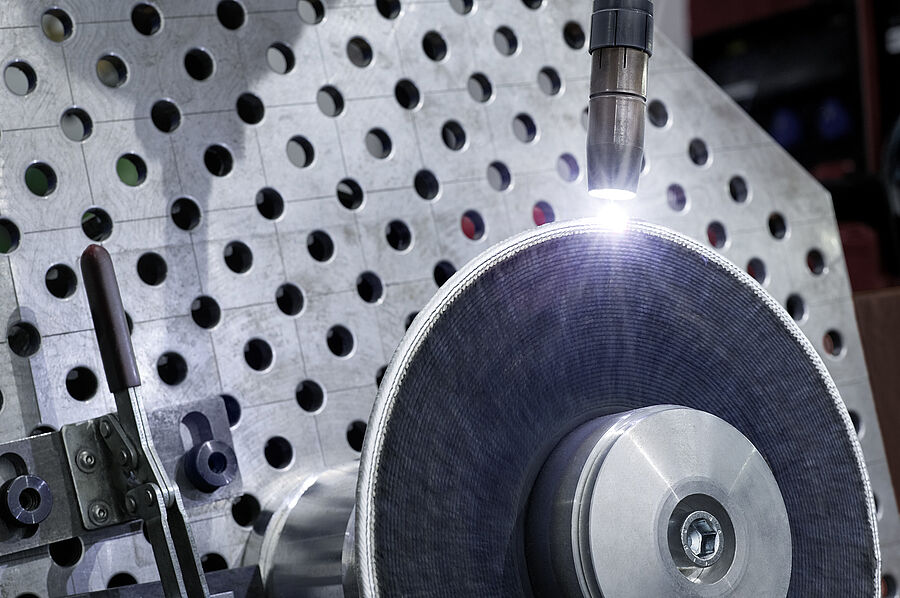

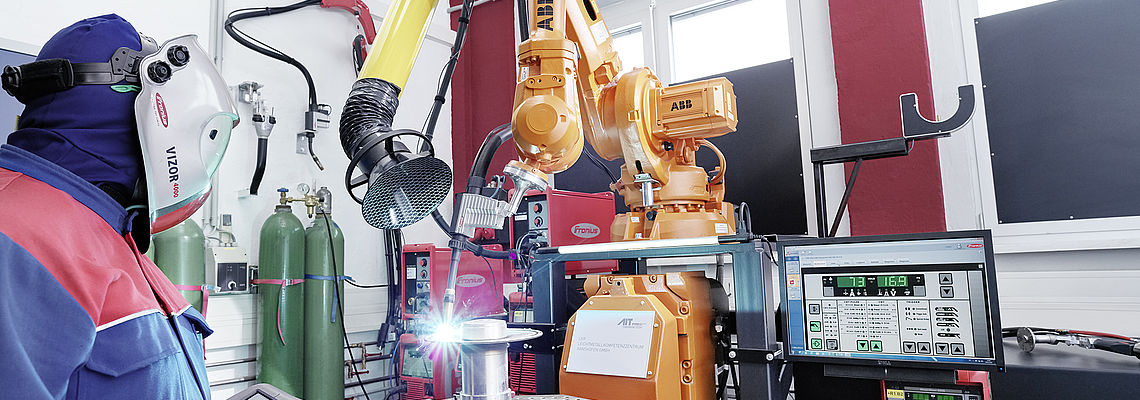

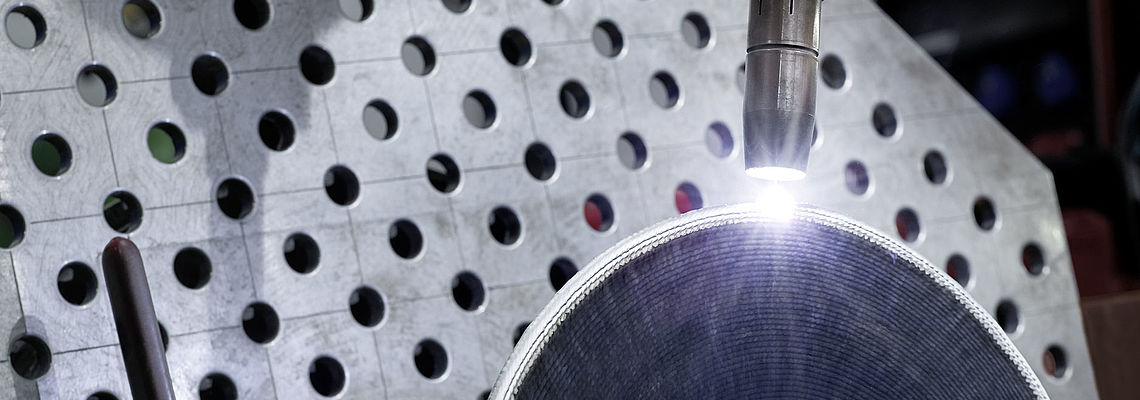

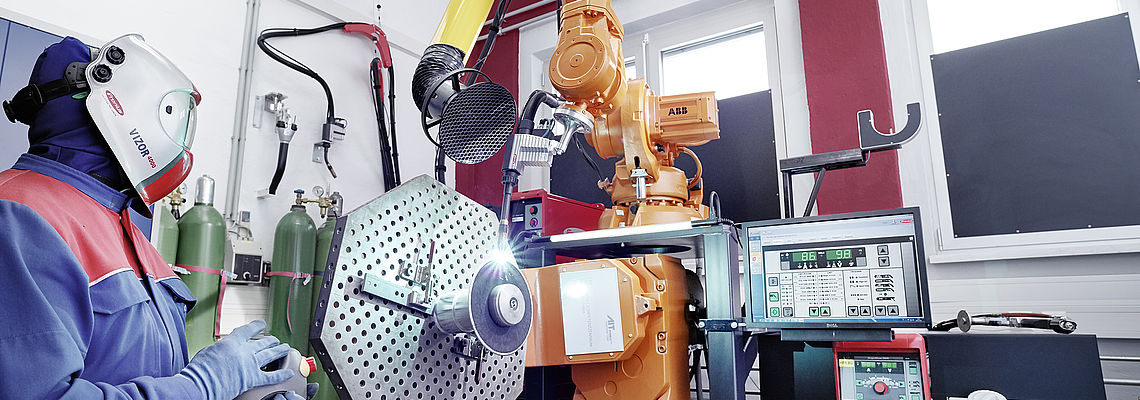

Conventional standard welding equipment is adapted in such a way that it enables component manufacture by direct metal deposition from welding wires at comparatively high deposition rates and theoretically unlimited component size. LKR is experienced in processing both, commercially available welding wires on aluminium and magnesium basis as well as purpose-made in-house material. The available equipment ranges from alloy development and preparation, in house horizontally and vertical casting machines, direct and indirect extrusion presses, wire drag – rig, CMT and plasma torch modules to latest WIG welding systems. Twin welding torches allow for the investigation of double wire supply concepts.

Methods for online monitoring and controlling the WAM process

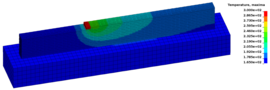

Numerical simulation of the temperature distribution while creating the layer structure of a WAM wall

Besides enhancing the suitability of the CMT and WIG welding systems for aluminium and magnesium materials, LKR has put the strategic focus of its research activities on the development of methods for online monitoring and controlling the WAM process. The goal is to create autonomous WAM deposition systems that can automatically adapt relevant process parameters in the case of quality deviations and thus take an optimizing and corrective action on part fabrication. Numerical methods to simulate the temperature distribution within WAM parts help to ameliorate process understanding at an early stage. In turn, this eventually supports the achievement of process stability on experimental level.

Our services

- Feasibility studies and concept development

- Fabrication of WAM prototypes and demonstrator parts

- Process and materials characterisation

- Optimisation of existing WAM processes

- Development of purpose-made WAM wires

- Analysis of WAM processes with numerical methods

- Material and component characterisation of AM products

![[Translate to English:] LKR Standort](/fileadmin/_processed_/2/8/csm_AIT_LKR_Standort_4fe61c1df0.jpg)