-

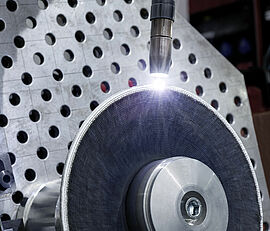

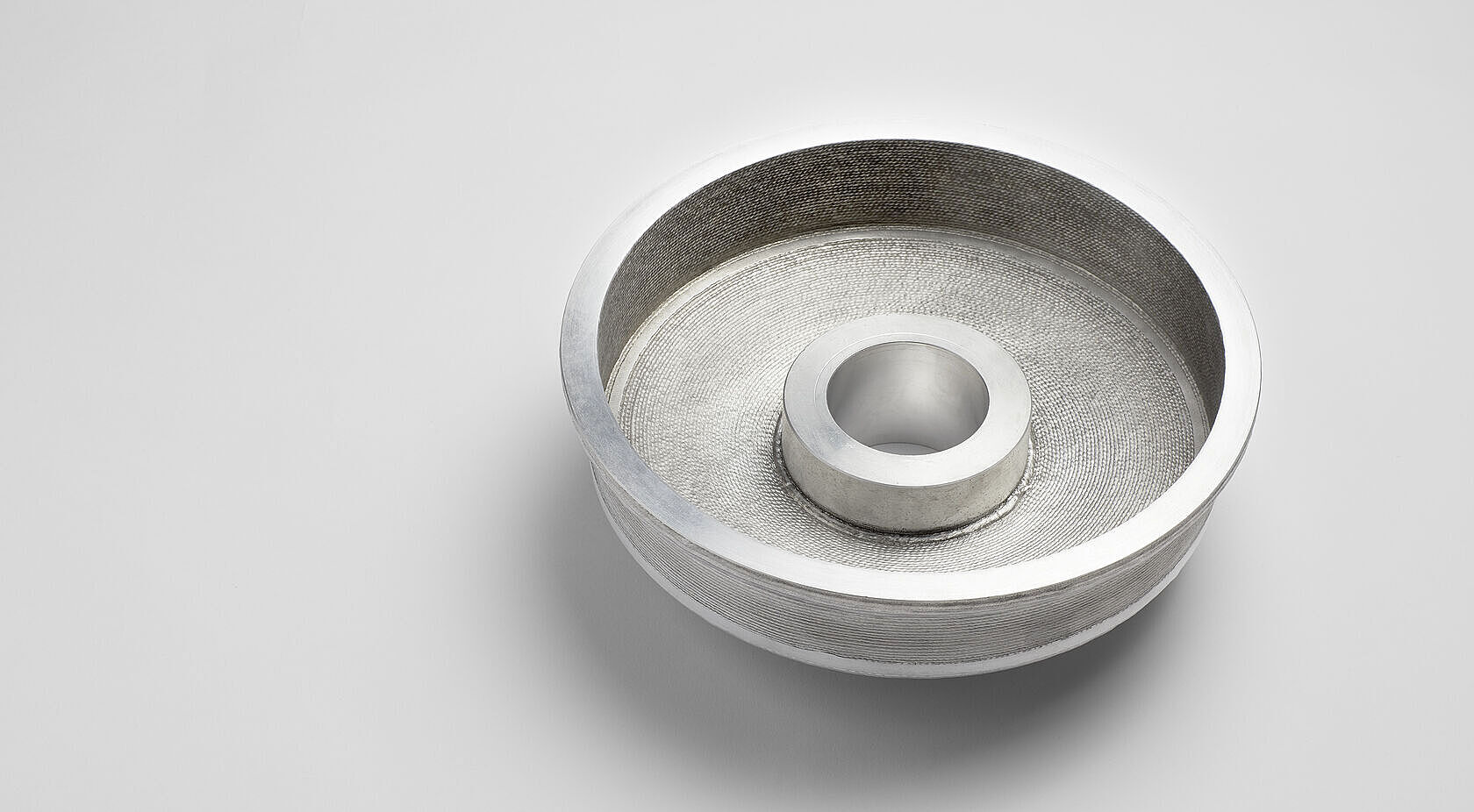

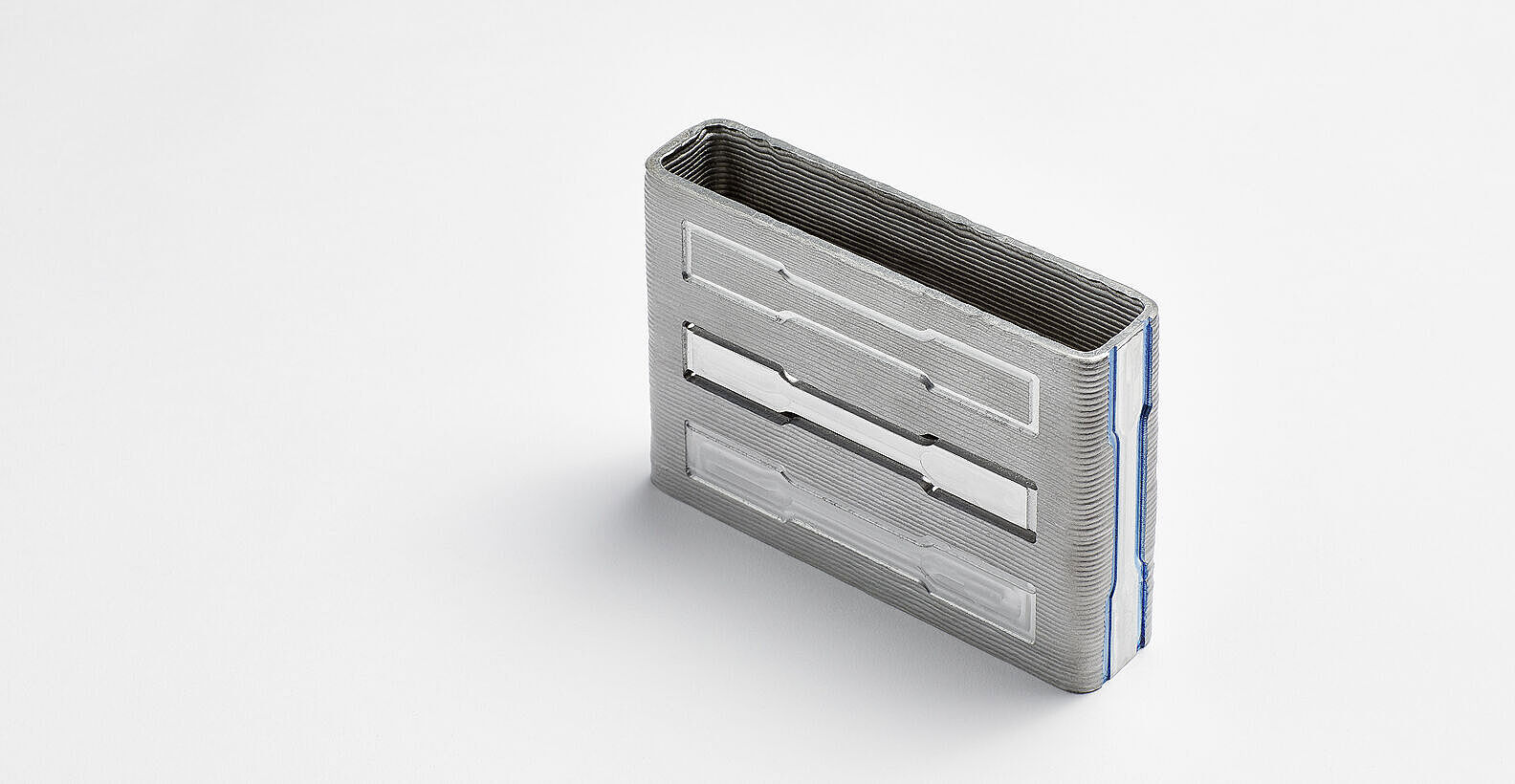

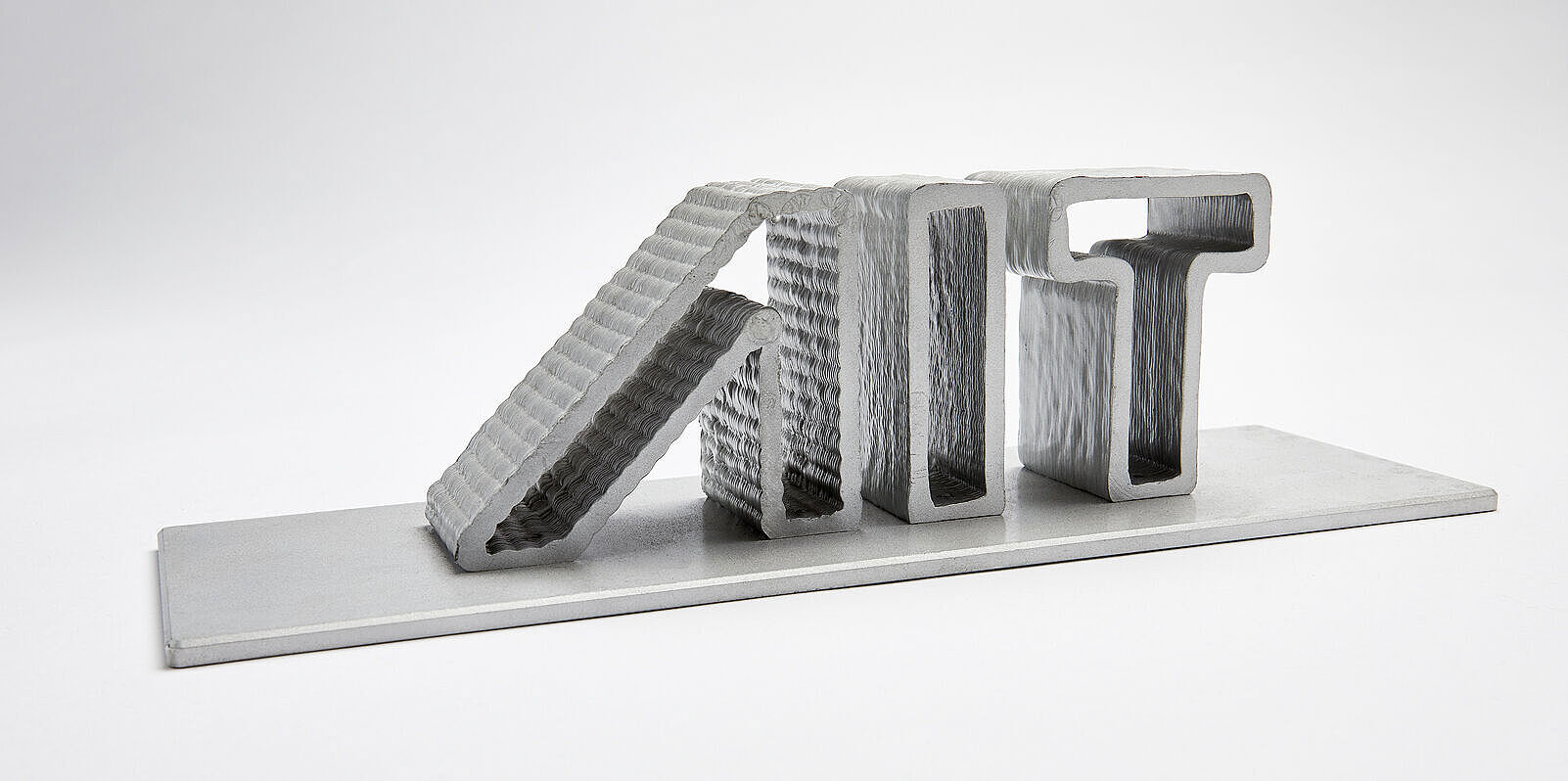

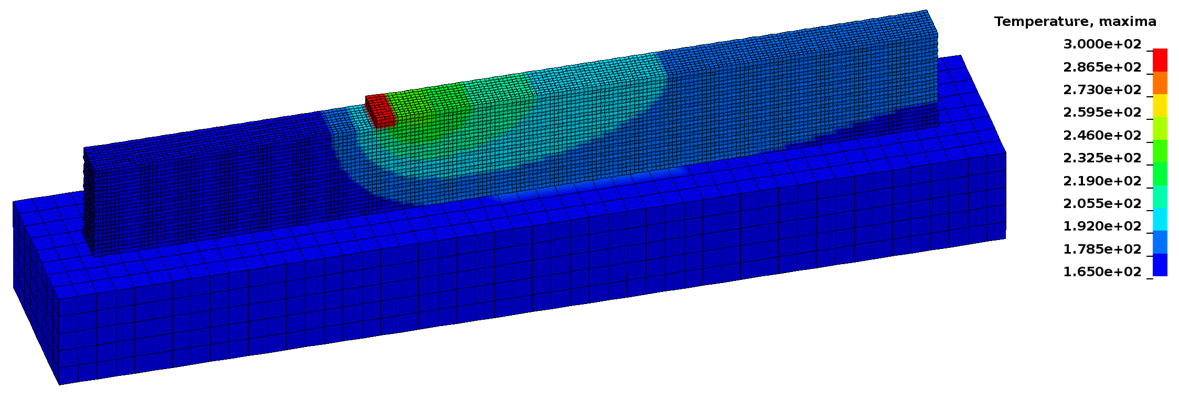

Production of 3-dimensional structures and components through layer by layer material deposition

-

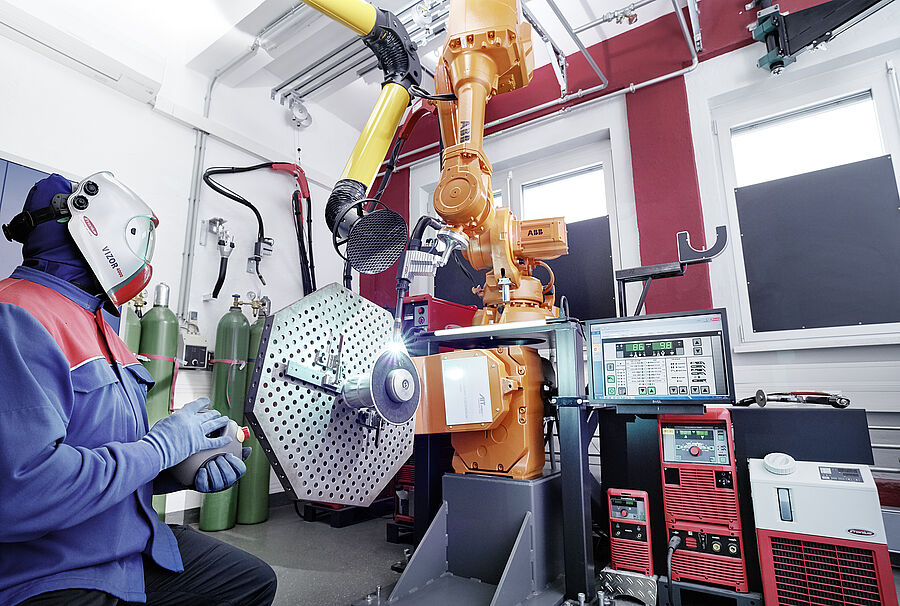

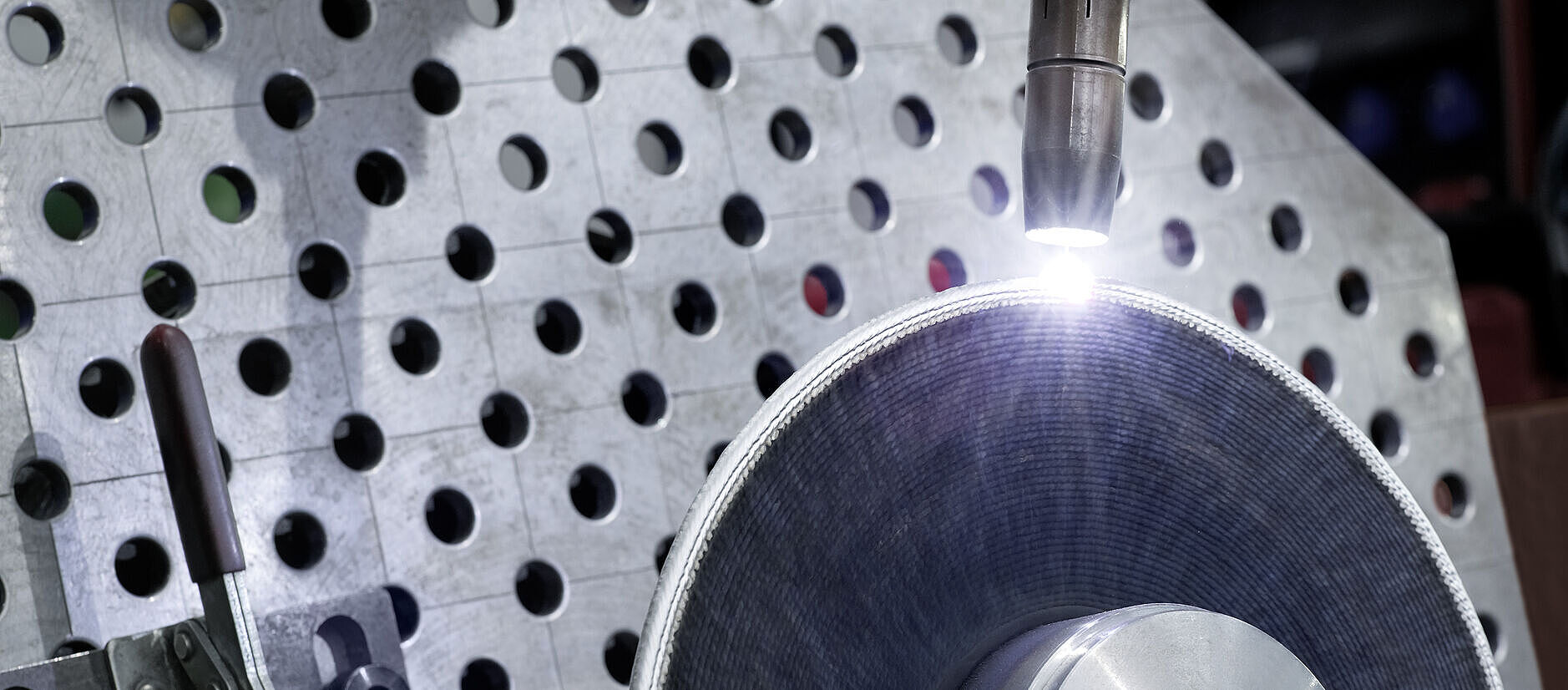

Direct Energy Deposition with standard and special wires (WAM)

Advantages of WAM

- Shortening of production and production development cycles

- Reduction of raw material

- Construction of complex component geometries

- Rapid prototyping

Possibilities

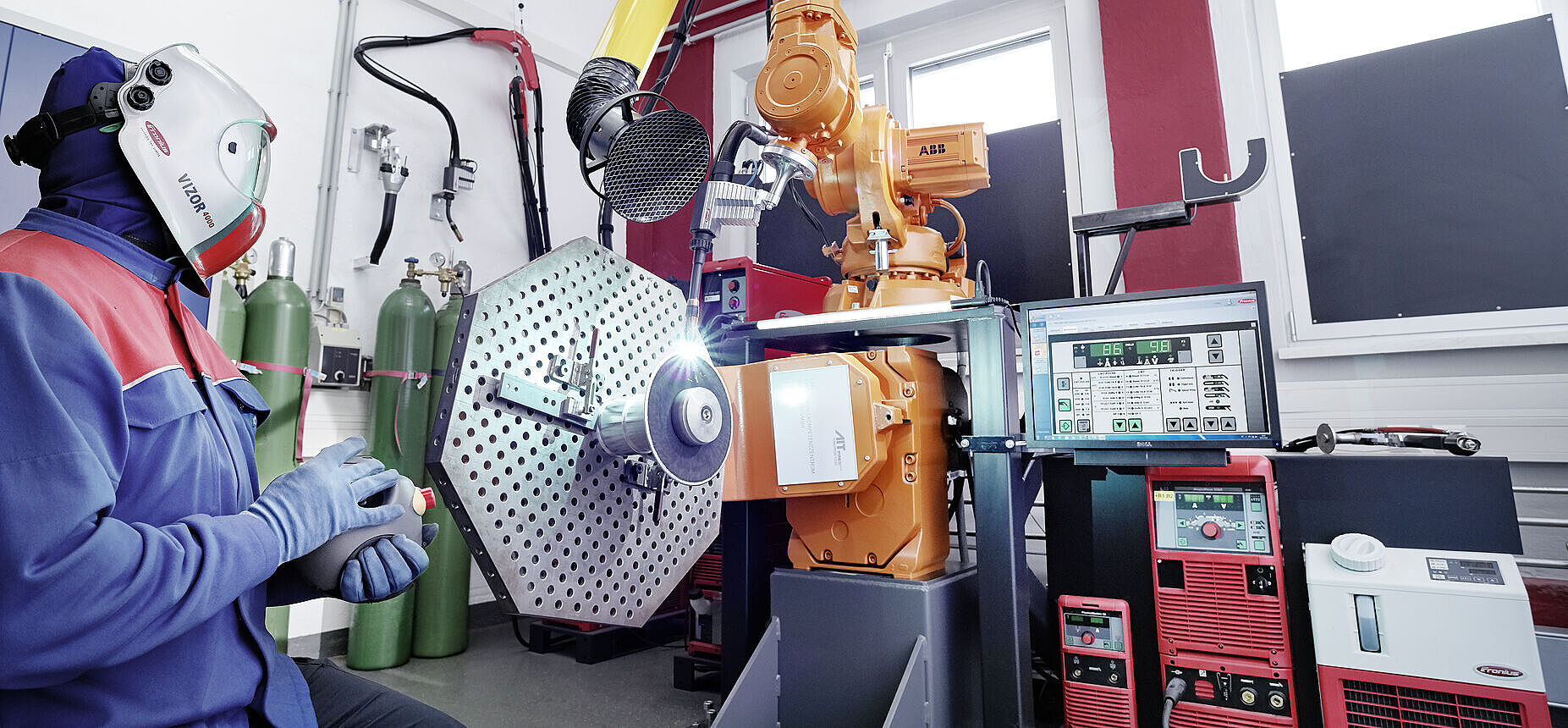

- Additive-Manufacturing Laboratory: Fabrication of WAM prototypes and WAM demonstrator parts

- Smart wire production route for development of targeted WAM wires

- Process and material characterisation

- Optimisation of existing WAM processes

- Consulting, concept development and feasibility studies

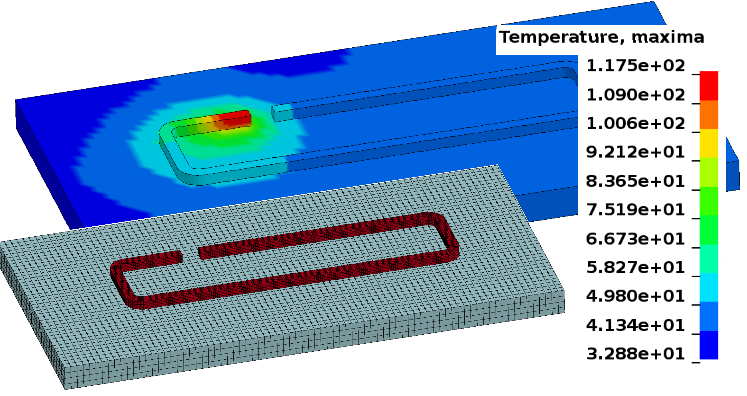

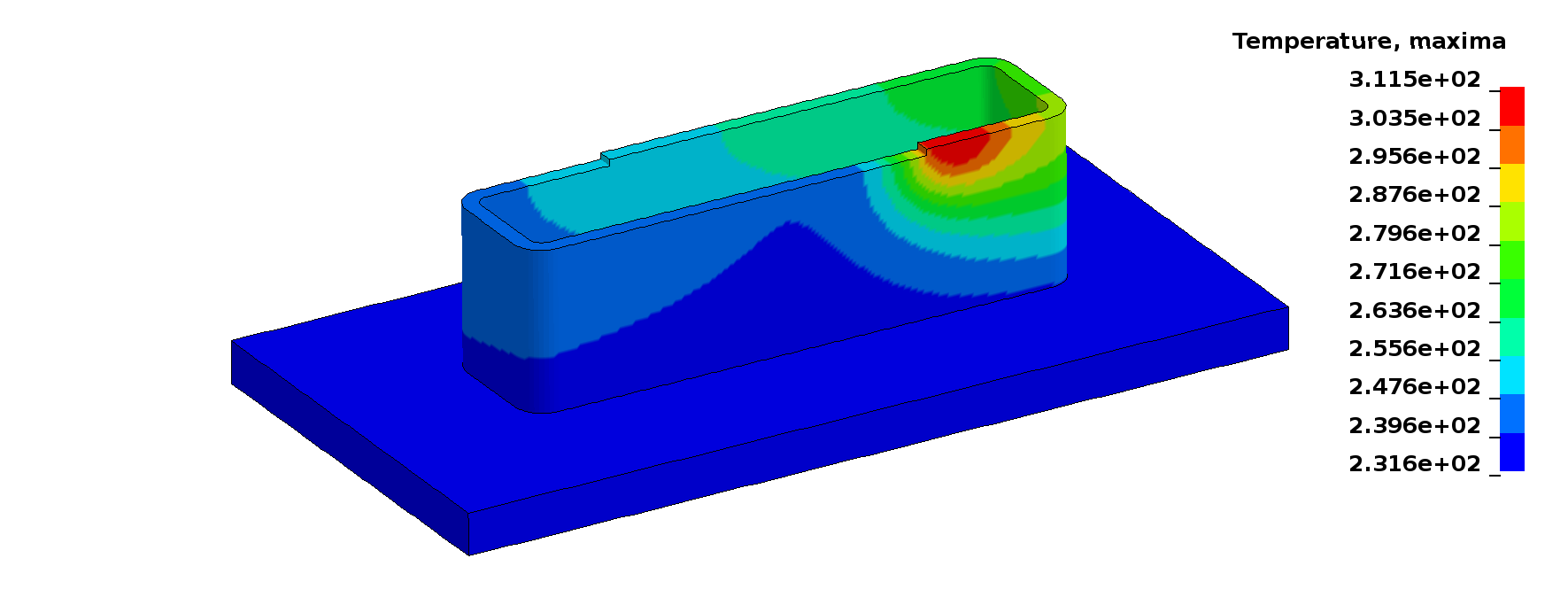

- Analysis of WAM processes with numerical methods

- Online process monitoring

- Calorimeters and efficiency measurements

- Environmental analyses (LCA)

- Dust measurements

- Welding camera & process sensor technology (Vitronik, nLIGHT Plasmo, Fronius and many more)

Technical Data

| Torch technologies (Fronius) |

| |

| Handling |

| |

| Test laboratory for various test setups |

|

![[Translate to English:] LKR Standort](/fileadmin/_processed_/1/f/csm_AIT_LKR_Standort_4fe61c1df0.jpg)