Functional Coatings for Energy Conversion and Hydrogen Technologies

Functional coatings play a crucial role in energy conversion and storage. Whether in solar technology or hydrogen applications, functional coatings enable more efficient and sustainable systems and pioneering technologies. The AIT Austrian Institute of Technology develops cutting-edge coatings and manufacturing processes that provide companies with significant competitive advantages in areas such as:

- Renewable Hydrogen

- Photovoltaics

- Optoelectronics, especially Transparent Electrodes

- Efficiency Improvement: Catalytically active coatings for enhanced efficiency and/or extended lifespan.

- Corrosion Protection: Protective layers preventing degradation of electrodes and electrolyzers.

- Cost Reduction: Replacement of expensive precious metals with more cost-effective materials.

Research, development, and innovation (R&D&I) in these areas are essential to improve the performance and durability of technologies and reduce market costs for renewable hydrogen.

The AIT offers technological solutions and innovative processes based on sustainable and cost-efficient materials to maximize component performance and reduce production costs.

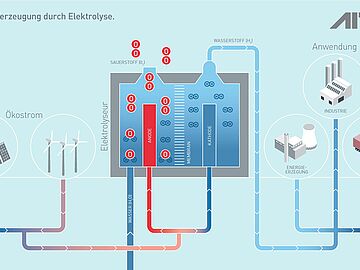

Functional Coatings for the Production, Storage, and Conversion of Renewable Hydrogen

Throughout the hydrogen value chain—production, storage, and conversion (into derivatives such as syngas, ammonia, or methanol, known as "Power-to-Gas/Liquid")—there are several challenges to improving the competitiveness of renewable hydrogen.

To address these challenges, the AIT develops functional coatings using innovative, sustainable, and cost-efficient materials in key areas:

Production:

- Efficiency Improvement: Catalytically active coatings for enhanced efficiency and/or longer lifespan.

- Corrosion Protection: Protective layers against degradation of electrodes and electrolyzers.

- Cost Reduction: Replacement of expensive precious metals with more affordable materials.

Storage:

- Higher Storage Densities and/or Increased Safety through protective coatings or innovative storage materials.

Conversion:

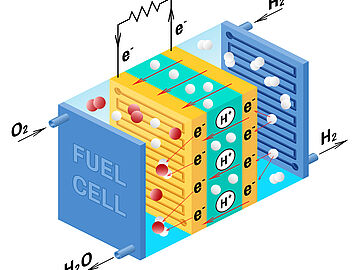

- Direct Utilization: Coatings for improved efficiency and/or lifespan of fuel cells.

- Derivatives (Ammonia, Methanol): Ammonia and methanol have a higher energy density and can be transported more easily than pure hydrogen. Ammonia can be used as an emission-free fuel or fertilizer, while methanol is a versatile chemical feedstock and can be used directly as a fuel.

- CCU (Carbon Capture and Utilization) Integration: CO₂ from industrial processes is used as a raw material for methanol, which closes the carbon cycle and reduces net emissions. The synthesis of methanol from CO₂ and green hydrogen supports the decarbonization of the chemical industry.

Functional Coatings for Photovoltaics

The AIT provides technological solutions and innovative processes based on sustainable, cost-effective materials to enhance the efficiency, extend the lifespan, and reduce the maintenance costs of PV modules.

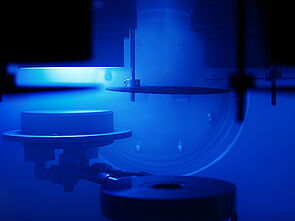

Functional Coatings for Optoelectronics

Transparent Electrodes: Beyond ITO (Indium Tin Oxide)

The AIT has developed transparent electrodes that replace or even surpass traditional ITO in some applications. These innovative electrodes are based on a combination of:

- Ultrathin Metals

- Dielectric Materials

Technical Properties of Transparent electrodes

On flexible PET substrates, these electrodes demonstrate:

- 85 % average visible transparency

- Sheet resistance as low as 5 Ω/sq

Application Areas of Transparent Electrodes

- Transparent Heaters

- Optoelectronics

- Flexible Electronic Components

These advanced properties unlock new possibilities for applications across multiple industries.

AIT: Comprehensive Services for Functional Coatings

The AIT offers customized solutions for companies looking to benefit from innovative technologies. The key services include:

1. Development Services for Hydrogen Technology in Energy Supply Systems

- Development of sustainable and cost-efficient materials, coatings, and lab-scale cells for:

- solid-state electrolyte-based electrolysis and fuel cell technologies (AEM, PEM, and SOEC).

- alternative renewable conversion technologies, e.g., photo-electrochemical, photochemical, and photovoltaic conversion.

- innovative hydrogen storage technologies, e.g., metal hydride- and LOHC-based processes.

- Characterization, evaluation, and modeling of physical, (electro)chemical, and electrical properties to assess and improve materials and components.

- Development and application of AI-driven digital methods for accelerated material development and characterization.

- (Field test) monitoring of electrolyzers and fuel cells on a lab scale.

2. Development Services for Hydrogen Technology in Industrial Processes

- Development of sustainable and cost-effective materials and coatings for components of:

- P2X Technologies: Power-to-Gas, Power-to-Fuel, and Power-to-Chemicals, e.g., catalysts for the production of sustainable synthetic syngas, ethylene, etc.

- High-temperature (co-)electrolysis technologies (SOEC).

- Technologies for hydrogen production from biogenic sources.

- Characterization, evaluation, and modeling of physical, (electro)chemical, and electrical properties for improved materials and components.

- Development and application of AI-driven digital methods for accelerated material development and characterization.

- Process and prototype development, including field test monitoring.

3. Development Services for Photovoltaics and Optoelectronics

- Development of sustainable and cost-effective materials, coatings, and lab-scale cells for:

- Innovative PV technologies, such as perovskite or tandem solar cells.

- Transparent electrodes.

- Characterization, evaluation, and modeling of physical, optical, and electrical properties to enhance materials and components.

- Development and use of AI-based digital methods for faster material development and characterization.

Advantages of AIT's Functional Coatings

Companies that adopt AIT technologies benefit from:

- Products with enhanced functionalities

- Maximized component performance

- Reduced environmental impact through sustainable materials and optimized processes

- Cost efficiency through innovative manufacturing methods

The versatility and flexibility of these advanced coatings allow their properties to be customized for specific requirements.

Functional Coatings: A Key to a Sustainable Future

Functional coatings are essential for the development of modern energy systems. They enable:

- Efficient utilization of renewable energies

- Advanced hydrogen technologies

- Sustainable solutions across various industries

The AIT supports companies in developing and implementing these technologies, ensuring a sustainable and competitive future.

Functional coatings play a crucial role in solar technology and hydrogen applications. Through innovative coatings and optimized manufacturing processes, the AIT provides cutting-edge solutions for energy conversion and storage.

Companies benefit from tailor-made technologies that offer maximum efficiency, cost savings, and sustainability. By advancing these technologies, the AIT contributes to ensuring the energy supply of the future.

Our Services

- Coating technology for high-performance transparent electrodes and functional thin films

- Development of new material combinations and innovative thin-film cell concepts

- Design of cost-efficient manufacturing processes

- Development of non-destructive and non-invasive methods for in-situ characterization

- Structural, optical, and photovoltaic characterization of materials and components

Your Benefits

- Products with new functionalities

- Higher manufacturing efficiency through process optimization

- Maximum component performance (e.g., transparent electrodes)

- Reduced environmental impact

- Lower production costs

- VERSATILITY, FLEXIBILITY, and CUSTOMIZED PROPERTIES – our material development platform enables a wide range of new applications.