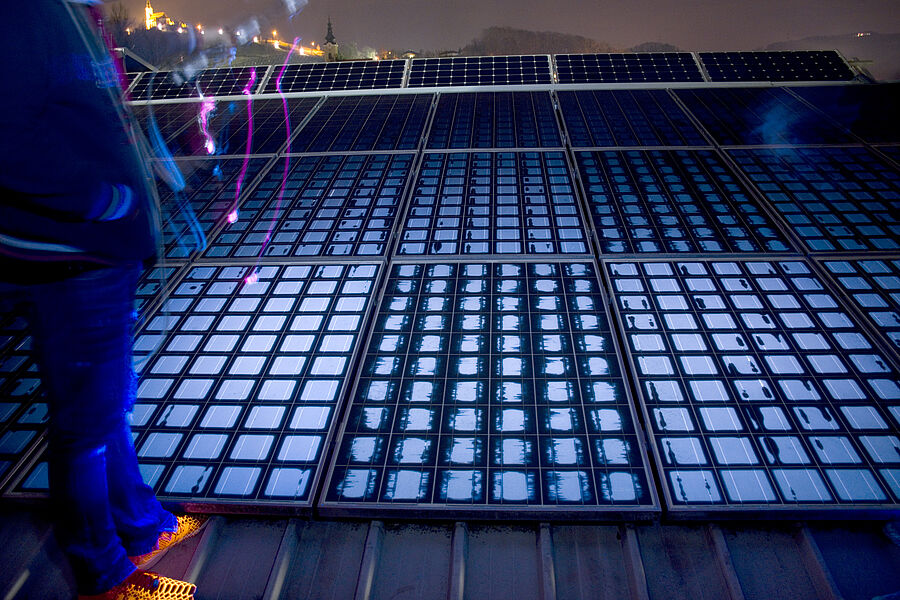

The photovoltaic laboratory of the AIT (Austrian Institute of Technology) stands for precision and innovation in the quality assurance of photovoltaic modules. With state-of-the-art technology and comprehensive testing procedures, the laboratory supports manufacturers, investors, installers and operators of PV power plants in the testing and validation of PV modules to ensure the highest standards of quality, safety and durability.

Testing PV modules: Our services at a glance

AIT offers a wide range of test procedures that are specially tailored to the requirements of current module technologies. The focus here is on

- Quality assurance for photovoltaic modules

- Testing and validation of PV modules for special applications

- Efficiency measurements

The tests are carried out in accordance with international standards (e.g. IEC 60904-1 Ed.3.0) in order to facilitate manufacturers' access to new markets and to confirm efficiency and effectiveness.

Quality assurance for photovoltaic modules

Quality assurance is a key aspect in ensuring that PV modules meet the requirements of installers, end customers and investors. The quality of modules is tested objectively and independently in the accredited AIT laboratory.

Key aspects of quality assurance:

- Long-term durability: accelerated ageing tests as proof that the materials and components remain stable even after years.

- Electrical safety: Minimization of risks such as short circuits or defects.

- Precise efficiency measurements: Confirmation of the module efficiency stated by the manufacturer (required for certain markets).

Testing and validation of PV modules for manufacturers

Testing and validation are essential to prepare PV modules for the global market. Manufacturers benefit from precise tests that reveal potential weaknesses at an early stage.

Our test procedures in detail:

1. static mechanical load testing

The load test simulates snow and wind loads to test the resistance of the modules. This ensures that the modules

- withstand a minimum load of 2400 Pa (approx. 2.4 kN/m²).

- no permanent deformations occur under high loads.

- remain fully functional with a power loss of less than 5 %.

Test examples:

Snow loads: Modules are tested with a load corresponding to ½ meter of granular snow.

Wind loads: Tests at speeds of up to 180 km/h.

2. module breakage test

These tests are similar to the pendulum impact test for safety glass and ensure that the risk of injury is minimized. A 45 kg impact body is dropped from a height of at least 30 cm to test whether

- the laminate is held securely in the frame.

- there are no openings that pose a safety risk.

- No large glass splinters are detached that could cause serious injury.

3. insulation test under wet conditions

To guarantee safety in humid environmental conditions, the electrical insulation is tested under rain, fog or dew conditions.

Highlights:

- Testing with system voltages of up to 1500 V.

- Limit values for insulation resistance are generally exceeded up to 100 times.

4. long-term analysis and reliability

A decisive criterion for PV manufacturers is the longevity of their products. PV modules must deliver reliable energy for decades. AIT offers comprehensive reliability tests in which modules are tested under extreme conditions to check their resistance to mechanical stress, temperature cycles, moisture and UV radiation. These long-term studies are essential for manufacturers to optimize the warranty performance of their products and minimize maintenance costs.

Accelerated ageing tests

- Long-term UV simulation (e.g. 25 years)

- Dynamic mechanical load tests

- Ammonia corrosion test

- Salt spray corrosion testing

- Methods for detecting PID and LeTID

Tests and certifications for PV modules and solar cells

- Precise power measurements (+-1.8% measurement uncertainty)

- Type testing of PV modules in accordance with IEC 61215 and IEC 61730

- Benchmarking of PV module types and supplier evaluation

- Measurement of bifacial PV modules (IECTS 60904-1-2)

- Quality measurements and accelerated ageing tests

- Test area of 3x3 m for modules of the highest performance classes

- Evaluation of component suppliers

- Validation before and after delivery

- Special expertise for thin-film and perovskite technologies

- Methods for the detection of PID and LeTID

Standards and guidelines for the approval of PV modules

The approval of photovoltaic (PV) modules is regulated worldwide by various standards and guidelines, which are intended to ensure that the modules are safe, efficient and durable. Here is an overview of the most important standards and guidelines:

International standards

- IEC 61215 (quality standard)

This standard evaluates the mechanical and electrical durability of PV modules under realistic environmental conditions. There are specific variants for different cell technologies, such as crystalline silicon (IEC 61215-1) and special specifications for the individual test methods (IEC 61215-2). - IEC 61730 (safety standard)

This standard specifies requirements for the safety testing of PV modules, including protection against electric shock, fire hazard and mechanical damage. It is divided into two parts:

Part 1: Design requirements

Part 2: Test methods

- IEC 61701 (Corrosion resistance to salt spray)

For modules used in coastal or marine environments. - IEC 62804 (Potential-induced degradation, PID)

Evaluates the susceptibility of modules to power degradation caused by electrical potentials. - IEC 62941 (Quality management)

Guidelines for quality management systems in the manufacture of PV modules.

European standards and directives

- CE marking

PV modules sold in the European Union (EU) must bear the CE mark. It confirms compliance with basic safety, health and environmental protection requirements. - Low Voltage Directive (LVD)

PV modules must comply with Directive 2014/35/EU, which regulates electrical safety at voltages below 1,500 V. - EMC Directive (Electromagnetic Compatibility)

According to Directive 2014/30/EU, PV modules and inverters must ensure that no electromagnetic interference occurs. - Ecodesign Directive (ErP)

Regulations on the energy efficiency and environmental compatibility of energy-related products.

Tests and certifications

Extensive tests are required for the approval of PV modules:

- Performance tests (e.g. current-voltage characteristics)

- Climate tests (temperature changes, humidity/heat tests, etc.)

- Mechanical load tests (e.g. snow load and wind pressure)

- Fire behavior tests

MEMBERSHIPS/STANDARDS COMMITTEES

CENELEC/IEC TC82, TC64IECEE CB Scheme OVE E03 (Austrian Electrotechnical Association)

Laboratory recognized by First Solar (PD-5-434 Rev 3.1 - Qualified Laboratories)

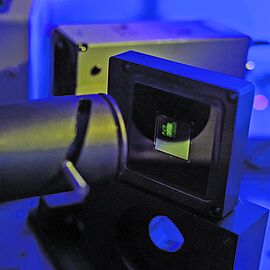

Analysis of the efficiency

Another focus of the AIT laboratory is the detailed analysis of the efficiency of PV modules. High-precision measuring devices are used to check how effectively modules convert sunlight into electrical energy.

Why is efficiency analysis important?

- Optimization of energy generation: Manufacturers can further develop their modules to maximize energy yield.

- Competitiveness: High efficiency is a decisive criterion for market success.

Measurement methods in the AIT laboratory:

- Spectral sensitivity and temperature coefficient measurement

- Yield measurement under simulated real conditions

Climate chamber: simulation of extreme environmental conditions

The climate chambers at the AIT are among the largest in Austria and make it possible to test photovoltaic modules under extreme conditions.

Features of the climate chamber:

- Temperature range: -75 °C to +180 °C

- Humidity tests: 10 % to 95 % relative humidity

- Rapid temperature changes: up to 6 °C/minute

With this unique infrastructure, manufacturers can ensure that their modules function optimally even under extreme climatic conditions.

Advantages of the AIT's testing services

Manufacturers who rely on the services of the AIT laboratory benefit from a number of advantages:

- Greater reliability: tested modules stand for quality and durability.

- Market access: Testing according to international standards facilitates market approval.

- Investment protection: Tested modules offer customers the security of a long-term return.

The AIT photovoltaic laboratory sets standards in quality assurance for photovoltaic modules, the testing and validation of PV modules and the analysis of efficiency. Manufacturers benefit from comprehensive support to establish their products on the international markets and meet the requirements of the future.

Frequently asked questions (FAQs)

1. what makes the AIT photovoltaic laboratory special?

The laboratory offers state-of-the-art testing procedures and is one of the leading test centers in Europe for PV modules.

2 Why are tests such as the static load test important?

They simulate real conditions such as snow and wind loads to ensure the safety and durability of the modules in combination with the substructure.

3. what is the task of the climate chamber?

The climate chamber simulates extreme temperatures and humidity conditions to test the load-bearing capacity of the modules.

4. does the AIT support the market approval of PV modules?

Yes, the tests comply with international standards and facilitate approval on global markets.

5. how exactly is the efficiency analyzed?

High-precision test benches are used to measure the conversion efficiency and energy yield of the modules.

Solar and environmental simulations

- Pulsed and steady-state solar simulation

- High UV irradiation (up to 250 W/m²)

- Cooling down to -75 ºC

- Weathering: rain, salt mist, snow, ice, dust and sand

- Simulation of heavy mechanical loads caused by wind, snow or hail

Electrical characterization and imaging analysis

- I /V measurements on PV prototypes, cells and modules

- EQE measurement, spectral analysis

- Electroluminescence, photoluminescence and IR-thermography

Materials analysis and production processes

- Scanning electron microscope (SEM), atomic force microscope (AFM)

- Sputtering system

- Electrochemical deposition (potentiostat/galvanostat)

- Optical and electron beam lithography