Screening and development of optimized materials for high temperature coils

Electrical Environmental Control Systems (E-ECS) feature many low power electromechanical actuators to ensure control and tuning of items such as high temperature valves of electrical systems in future airplanes. They also include motorized turbomachines with power electrical motors.

The aim of the Cleany Sky 2 project HTcoils and its partners (HPW High Performance Wires, PEAK Technology and coordinator LKR Leichtmetallkompetenzzentrum Ranshofen) was the development of high-temperature, high performance wires, impregnating varnishes and potting ingredients (resins) with an increased thermal index value . Besides required materials development it was further goal to manufacture sufficient wire materials for sub-assembly coils tests, final demonstration and qualification of high temperature coil systems and to test their functionality in electromagnet actuators for different applications in an aeronautic Electrical Environmental Control System (E-ECS).

The main objectives were:

- to develop specific wires, impregnating varnishes and potting ingredients (resins) to have complete solutions for high temperature coil and qualify these ingredients

- to manufacture high temperature coils with these ingredients, integrate them in the Topic Manager’s defined application and demonstrate that the solutions proposed can be industrializedall solutions have to comply with aeronautical constraints (electrical, vibration, lifetime, manufacturing process, etc.) according to RTCA/DO-160.

The main results of HTcoils can be summarized as follows:

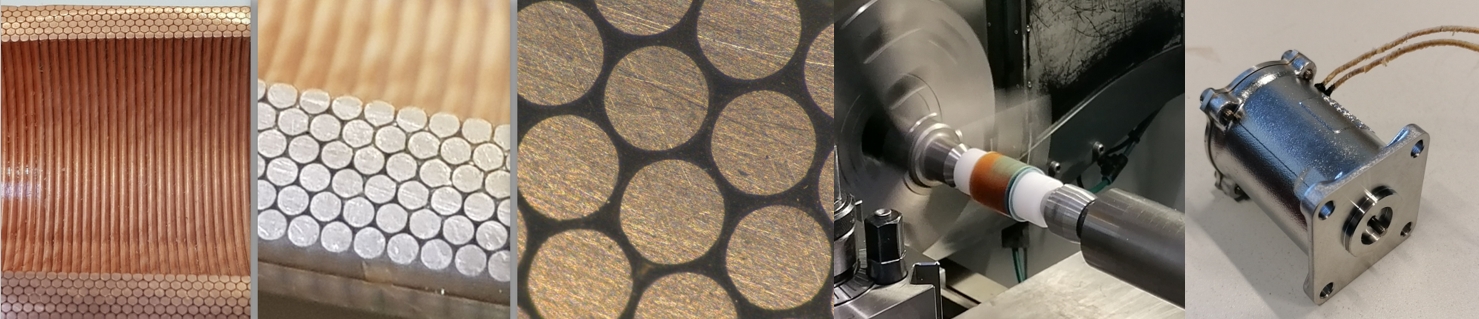

- HPW developed a very thin, high temperature wire (incl. varnish) with a final diameter of 0.70mm The wire material proved its durability over 20.000 hours thermal testing leading to a thermal-like index of 274°C

- Compared to the baseline TLI 240°C this is an increase of +14.6%

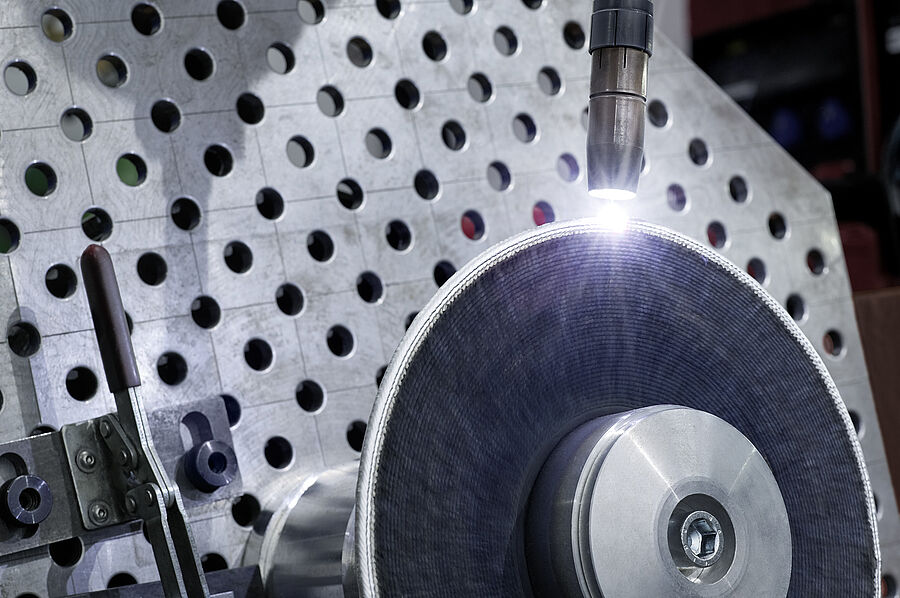

- PEAK realized a manufacturing route (coil winding + potting) for the novel high temperature conductor wires

- PEAK showcased coil manufacturing including final demonstrator assembly

- PEAK demonstrated the final actuator functionality on demonstrators.

Future Benefits of the novel high temperature wires (TLI 274°C):

- Use of actuators at higher environment temperatures

- Enabling the design of smaller, lighter actuators hence saving structural mass

- Realization of better trade-off for aircraft heating management hence contributing to CO2 emission reduction

- Exploitation of actuators from aeronautics to electric car technologies

- Stay at forefront of material development (HPW), process development (PEAK) and electric actuator technologies (LTS) with the results achieved.

Project Data

Programme

H2020-CS2-CFP06-2017-01

Duration

March 2018 - May 2021

Project coordination

LKR Leichtmetallkompetenzzentrum Ranshofen

Topic Manager

Liebherr-Aerospace Toulouse SAS

Project partners

- Peak Technology GmbH

- hpw Metallwerk GmbH (former Gebauer & Griller Kabelwerk GmbH)