The AIT Austrian Institute of Technology has many years of know-how as an independent testing laboratory for shock and vibration tests and environmental simulations accredited according to ÖVE/ÖNORM EN ISO/IEC 17025. Using two electrodynamic shakers in combination with or without a climatic chamber, tests are successfully performed for electronic and electrical components, devices, machines and systems as well as superstructures for vehicle parts. We advise our customers in the selection of test methods, offer competent and customer-oriented testing and issue accredited test certificates.

NEW SINCE 2018: SHOCK TESTS UP TO 100 G

Shaker tests at AIT

- Vibration: Sine and broadband vibration with and without climate chamber

- Mechanical shock: single and continuous shock with and without climate chamber

- Accredited test center for shock and vibration tests

Services

- Selection of test methods

- Creation of practice-oriented test plans

- Execution of the tests

- Performance of approval tests

- Support in product development

- Long-term and endurance tests

- Preparation of test reports, certificates and expert opinions

AIT test facilities

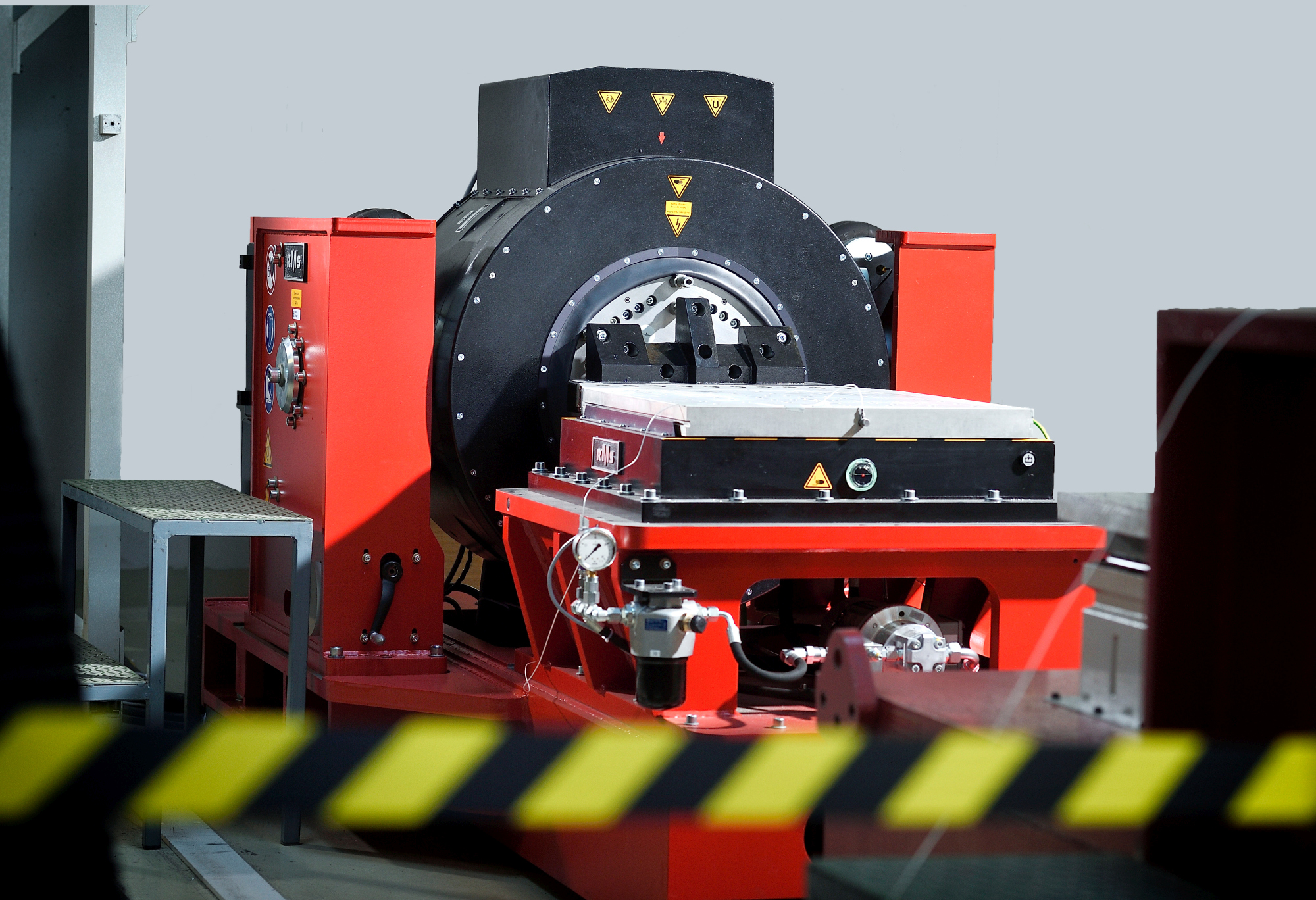

Electrodynamic shaker 1

- Type: RMS SW9112-80-LS3

- Horizontal sliding table

- Maximum force 80 kN (sine/noise excitation)

- Maximum force 160 kN with shock excitation

- Maximum travel 76.2 mm (3 inch peak - peak)

- frequency range: 5 - 2500 Hz

- Maximum acceleration 100 g

(test piece mass and equipment up to 45 kg) - Test in 3 axes xyz possible

- Payload typically up to 300 kg, nominal up to max. 500 kg

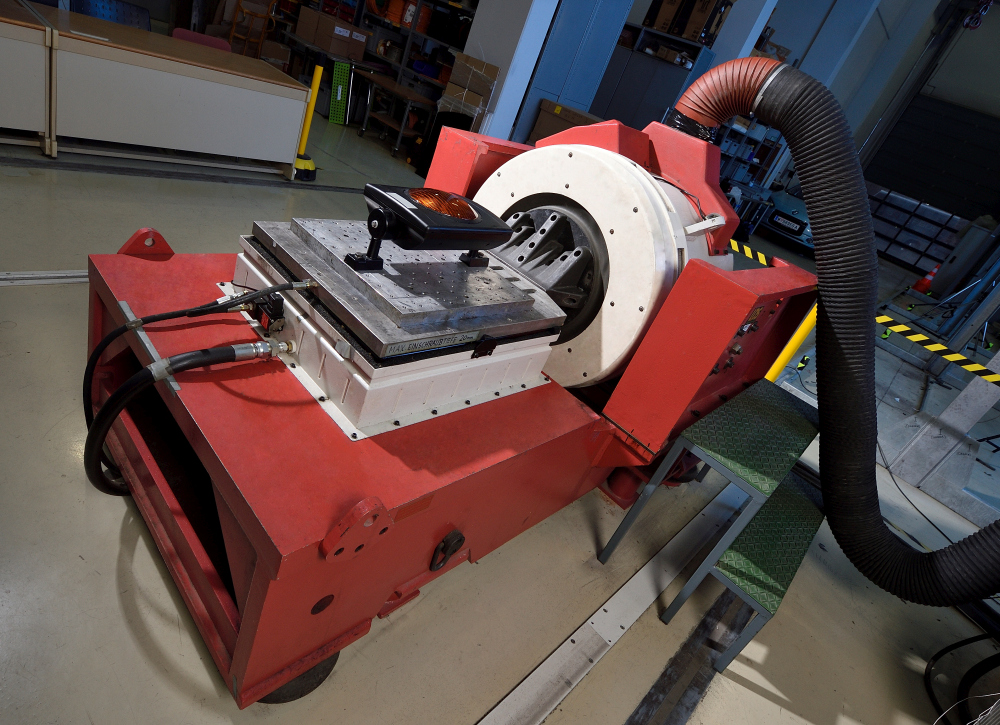

Electrodynamic shaker 2

- Type: LDS V864HT-440 / HBT 600 Combo

- Horizintal sliding table

- Maximum force 35 kN

- Maximum travel 50.8 mm (2 inch peak - peak)

- Frequency range: 5 - 2500 Hz

- Maximum acceleration: vertical 109 g (unloaded)

- Test in 3 axes xyz possible

- Payload typically up to 300 kg, nominal up to max. 500 kg

Climate chamber

- Type: Vötsch climatic test chamber VCV 7100-5/S air-cooled

- Temperature range: -70 to +180 °C

- Maximum temperature change speed: +7°C/min or -5°C/min

- Relative humidity: 10% - 95% relative humidity

- Max. test material dimensions: approx. 500 x 500 x 800 mm3