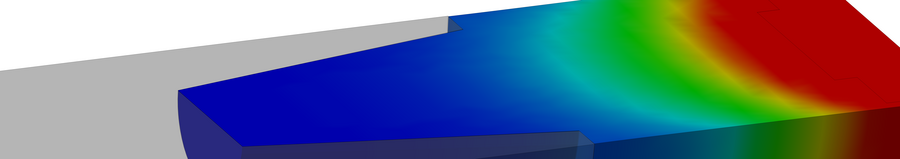

Simulation of the metal extrusion process to improve tool designs, optimize process parameters and thus improve process performance

The simulation of the metal extrusion process is intended to provide a deeper understanding and better process analysis. Due to the encasted material inside of the container in extrusion processes, experimental investigations are difficult to perform.

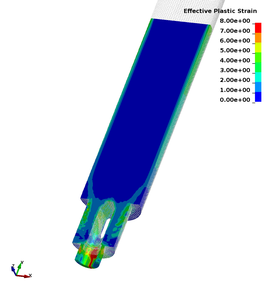

However, due to the large deformations during metal extrusion, numerical methods are also faced with a great challenge. In Finite Element (FE) methods large deformations lead to large element distortions which have to be tackled by remeshing or alternative methods to conventional FE methods.

LKR is both using Volume of Fluid (VOF) based commercial simulation software packages (HyperXtrude) and developing simulation strategies based on Element Free Galerkin (EFG) method implemented in the commercial FEM software LS-DYNA®.

Currently, HyperXtrude is used to simulate industry related models, EFG based simulations are currently performed in the context of Through Process Modelling (TPM) and linking/coupling to external software (MatCalc, preCICE,…). In TPM simulation sequences, production processes are considered e.g. from casting to the final product.

![[Translate to English:] LKR Standort](/fileadmin/_processed_/2/8/csm_AIT_LKR_Standort_4fe61c1df0.jpg)