The AIT Austrian Institute of Technology team was awarded third prize at the International Institute for Sugar Beet Research (IIRB) Congress in Brussels for its groundbreaking research in the field of optical, automated quality control of sugar beets. This recognition underscores the importance of their innovative technology in enhancing sugar production efficiency.

Currently, in Austria, approximately 2.4 million tons of sugar beet are processed annually to produce 466,000 tons of sugar (source: statista). Sugar beets are harvested in the fall. At this time, several tons of beets are transported daily to factories for sugar processing. The remainder are stored temporarily in fields, a critical phase for the sugar beet due to varying weather conditions. In addition, damage to the beet body during harvest, animal damage, soil buildup and foliage create vulnerabilities for microorganisms such as bacteria and fungi that degrade the sugar in the beet, significantly reducing sugar yield.

After harvest and until processing, sugar beets are temporarily stored in the field, which can have a negative impact on the sugar yield. Photo credit: AIT

Breeding resistant sugar beet varieties

To mitigate these issues, trials have been conducted to breed sugar beet varieties that are more shelf-stable, resistant to microorganisms, and promise the highest possible sugar yield. Previously, the documentation of these trials was manual and time-consuming. Automated documentation could streamline this process, enabling objective evaluations of beet quality and quantity. It could also facilitate predictions about expected sugar yield.

Camera-based automated quality inspection and objective evaluation criteria

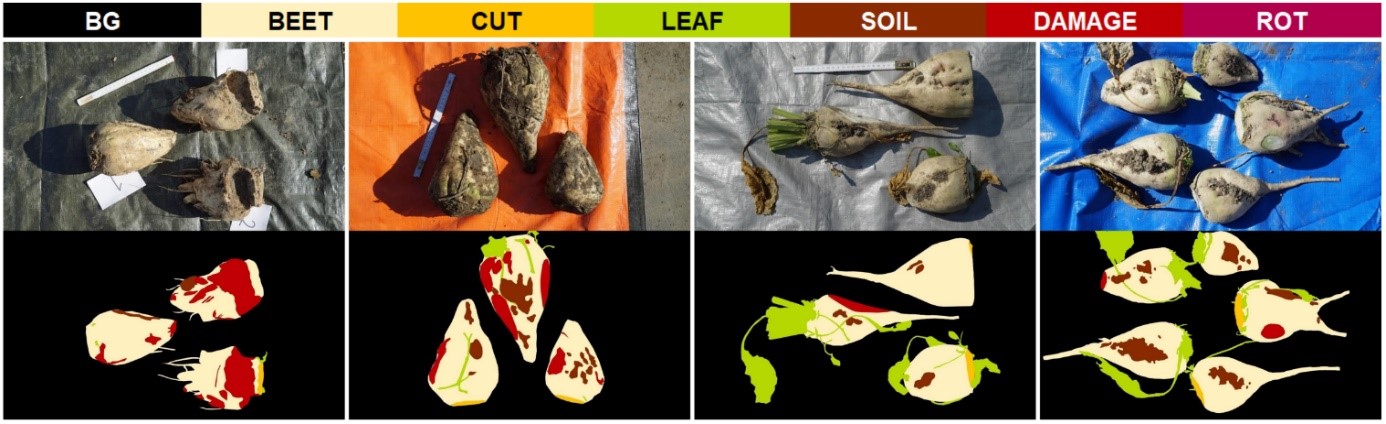

Researchers in the Assistive & Autonomous Systems Group at the AIT Center for Vision, Automation & Control have taken up this challenge developing an automated inspection method to efficiently detect and measure damage and contamination on sugar beets. They compiled a large dataset of annotated images to train a neural network. Their approach, which relies solely on colour images, provides a precise and objective analysis of dirt adhesion, the number of leaves, and damage. It thus supports reliable statements about the quality of the beet bodies.

New data set: For the research work, around 1180 sugar beets were harvested and photographed under different weather and light conditions. Each pixel was assigned to one of seven classes (background, beet, cut, leaf, soil, damage, rot). Photo credit: AIT

With impressive accuracy in estimating beet weight on the one hand and impurities on the other, the technology is also suitable for determining the actual weight of sugar beets. This supports fair purchasing for both beet growers and sugar manufacturers.

Future directions

Further research and methodological improvements are planned to automate the breeding and rating (quality assessment) of new sugar beet varieties with improved storability. To this end, scientists from two AIT Centers, the Center for Vision, Automation & Control and the Center for Health and Bioresources, are intensifying their collaboration to develop novel AI methods that combine image material and various molecular markers.

Recognition at the IIRB Congress

The International Institute for Sugar Beet Research (IIRB), an international, non-governmental, non-profit organization aims to advance sugar beet production. IIRB provides a platform for networking and knowledge transfer among scientists and experts in sugar beet cultivation and organizes the congress bearing its name.

The AIT poster was awarded 3rd place out of 115 poster presentations, celebrating its clarity, scientific nature and contribution to the sugar beet industry.

We congratulate the AIT scientists GERARDUS CROONEN, ANDREAS TRONDL, DANIEL STEININGER on this well-deserved success.