The manufacturing industry is increasingly confronted with a diversification of products and, at the same time, strongly fluctuating batch sizes. This development requires a high degree of flexibility and adaptability in order to remain competitive. Within the framework of several research projects with Festo SE & Co. KG, scientists from the Complex Dynamic Systems research group at the AIT Center for Vision, Automation & Control and the Institute of Automation and Control Engineering at the Vienna University of Technology have developed the control technology for a two-stage pneumatic valve. It is part of a compact valve block that is versatile in production plants and covers a wide range of pneumatic applications. This makes it an indispensable component for future automated production.

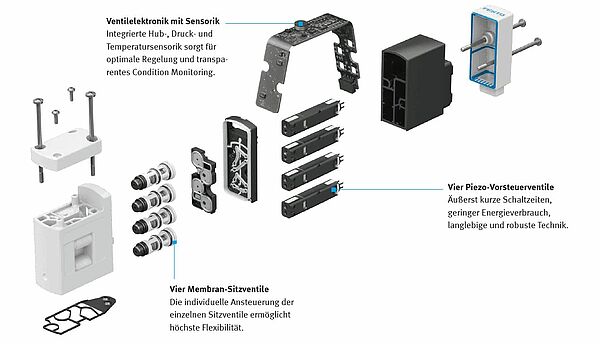

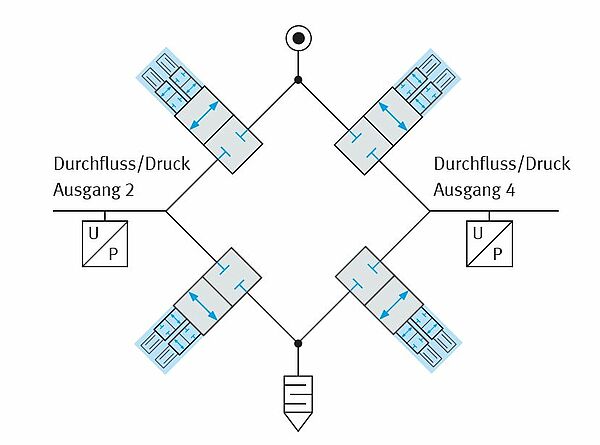

Each valve block consists of four two-stage pneumatic valves. These in turn contain an energy-efficient, piezoelectric preliminary stage and a tappet valve as the main stage. They are interconnected to form a full bridge. In addition, the valve block contains a powerful computing unit and sensor technology. This makes it possible to simulate the function of different valve types, such as directional control valves, switching valves, etc., with a single intelligent valve block - in contrast, a special solution was previously developed for each application. A suitable valve had to be kept ready for each application. The associated costs for accessories, storage, assembly and configuration are now eliminated and energy consumption is reduced.

All in all, the universal valve block can be used for a wide range of applications and save resources.

In their paper "Modeling and control of a novel pneumatic two-stage piezoelectric-actuated valve", the scientists present the special architecture of this novel pneumatic valve as well as the specially tailored mathematical modeling and model-based control.

The paper

Tobias Glück, Dominik Büchl, Christian Krämer, Andreas Pfeffer, Andreas Risle, Lena Hägele, Andreas Kugi

Modeling and control of a novel pneumatic two-stage piezoelectric-actuated valve

Mechatronics, Volume 75, 2021

102529

ISSN 0957-4158

doi.org/10.1016/j.mechatronics.2021.102529.

https://www.sciencedirect.com/science/article/pii/S0957415821000313

Abstract

In manufacturing automation, there is a strong need for highly integrated intelligent components and subsystems. In this context, a novel two-stage pneumatic piezoelectric-actuated valve has recently been developed. It covers a wide range of pneumatic products and functions in one compact component and enables flexible and adaptive plant operation. The valve consists of four poppet main-stage valves that are driven by piezoelectrically actuated pre-stage valves and includes pressure sensors as well as a powerful computational unit. This work presents the systematic development of a model-based position control algorithm including modeling, identification, and controller design. The control concept comprises a hysteresis compensation based on the Prandtl–Ishlinskii operator theory, a flatness-based feedforward controller, and a PI feedback controller with appropriate anti-windup measures. Measurement results from a test bench demonstrate the performance of the proposed concept.

More on

AIT research group Complex Dynamical Systems