Innovative anode materials for more powerful and sustainable batteries

Modeling and development of silicon-tin sulfide composite anodes for generation 3b lithium-ion batteries

The world is facing a key challenge: the increasing demand for energy, particularly through electromobility, requires more powerful and sustainable energy storage systems and a growing share of renewable energies. Lithium-ion batteries (LIBs) play a key role here, but their further development is hampered by limited resources, environmental pollution and technical limitations of existing materials. Dependency on critical raw materials such as natural graphite and cobalt not only poses a supply risk, but also raises ethical and ecological questions. At the same time, conventional carbon-based anodes are reaching their capacity limits, which requires new material concepts to meet the increasing demands on energy storage.

This is precisely where the AIT-led research project MoSiLIB comes in, developing an innovative composite anode based on silicon and tin sulfide (SnS2). The aim is to avoid the disadvantages of previous anode materials, to reduce the use of critical raw materials and at the same time to significantly improve battery performance and cycle stability. A particular focus is on the use of high-purity silicon recycled from disused solar modules. This strategy contributes to the conservation of resources and sustainability.

The chemical interaction of SnS2 with silicon results in Si/Li2S and Sn/Li2S heterostructures that buffer the volume expansion of the anode particles and reduce agglomeration during charging cycles. This increases the battery life, which makes the composite anode particularly suitable for 3b generation LIBs with LNMO cathodes. In addition, the project relies on environmentally friendly, water-based processing methods and scales the technology to a semi-industrial level to ensure feasibility and industrial applicability.

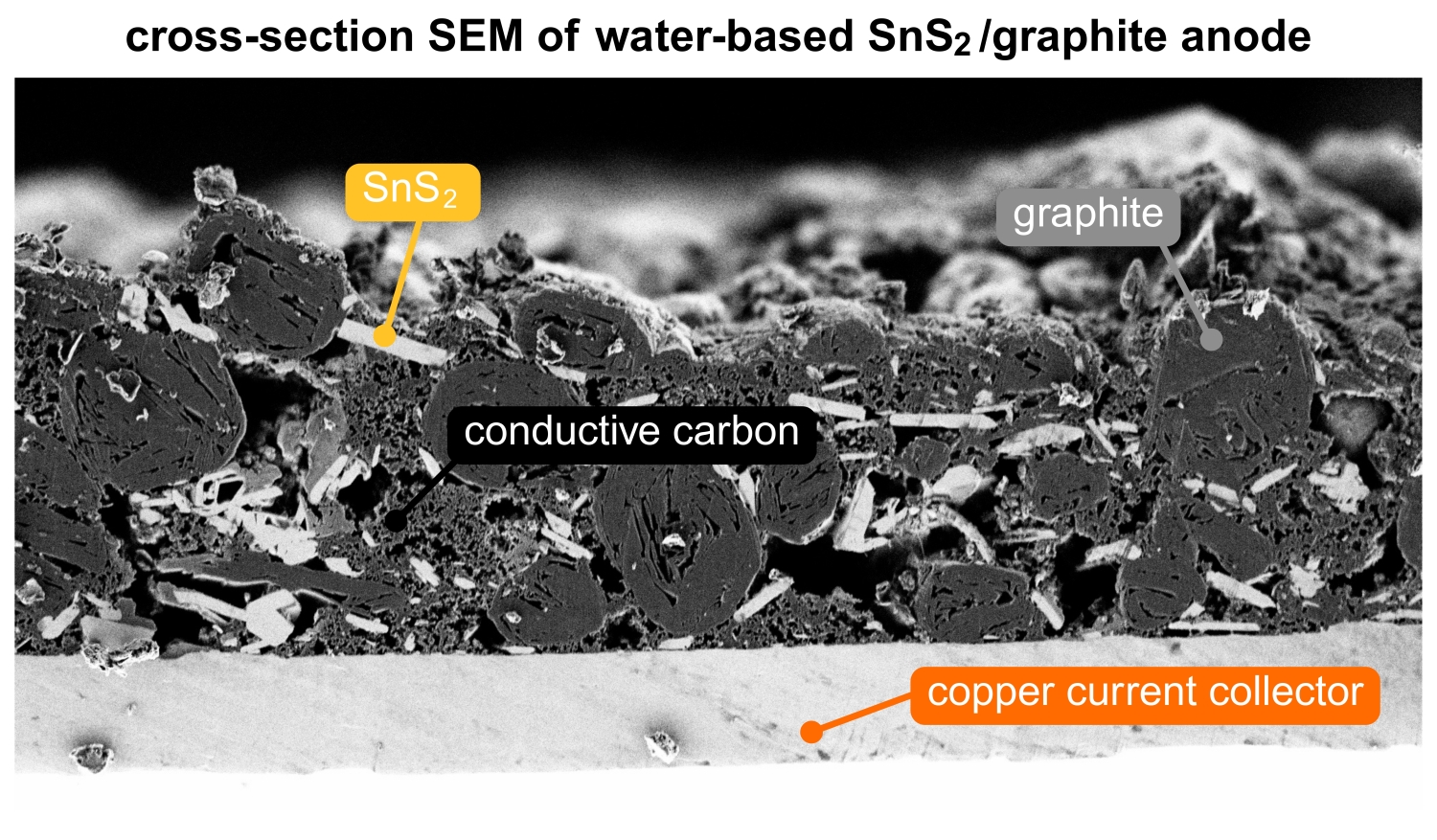

Cross-section of an anode made of SnS₂ and graphite, developed in MoSiLIB, coated with a water-based formulation and imaged using a scanning electron microscope. (c) AIT/Jana Kupka

Project objectives and methods

The main objective of MoSiLIB is to develop a Si (graphite) -SnS2 composite anode that achieves a reversible capacity of 800 mAh/g over more than 1000 cycles. For this purpose, a novel material processing is used that is based on a combination of spray drying and high-energy ball milling. The resulting anode materials will be tested in full high-voltage cells with LNMO cathodes.

In addition to experimental research, the project relies on multi-scale modeling to optimize the performance of the anode materials and to understand aging mechanisms in detail. In addition to material development, a further focus is on the semi-industrial scaling of the synthesis processes and water-based electrode production to ensure sustainable and economical production. The newly developed anode materials will be extensively tested in coin and pouch cells, including multilayer pouch cells, to validate their long-term performance and scalability.

Contribution of AIT Austrian Institute of Technology

AIT plays a central role in MoSiLIB. In addition to project management and coordination, AIT is particularly focusing on electrochemical investigations of the SnS2 anodes and LNMO cathodes. The aim is to evaluate their performance and long-term stability under real operating conditions.

Another focus of AIT is the development and optimization of processing methods for electrodes on a pilot scale. The scalability of the processes is investigated and further developed using state-of-the-art pilot plants to enable the most sustainable and economical production of silicon-tin sulfide composite anodes possible.

“With MoSiLIB, we are taking a decisive step towards sustainable and high-performance lithium-ion batteries. By combining innovative materials and environmentally friendly manufacturing processes, we can not only improve the efficiency of batteries, but also reduce their ecological impact. This is an essential contribution to the energy storage of the future and the further development of electric mobility,” explains AIT researcher Damian Cupid, who is coordinating the project.

The project is funded by the Austrian Research Promotion Agency (FFG).