Crack monitoring and crack evaluation of concrete structures

Cracks and their alterations are essential indicators of load conditions in structures. Based on distributed fiber optic measurements, crack measurements can be performed with fiber optic cables subsequently bonded to the structure. By means of new evaluation algorithms based on measurements of rayleigh backscatter, cracks can be identified and very precisely located using inexpensively attached fiber optic cables, and the crack width changes can be measured in the µm range. Even individual cracks can be measured at the usual crack spacing in reinforced concrete construction (approx. one crack every 15 cm).

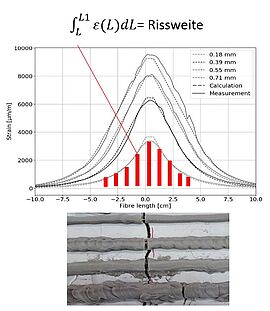

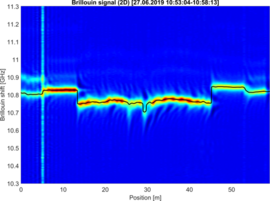

From the measurement signal, cracks are detected as peaks. Thus, the crack openings can be calculated from the integral of the measured strains.

The applicability of the distributed fiber optic crack monitoring system developed in the course of the laboratory tests was developed and demonstrated within the FFG project RIBET.

When using matched fibers and adhesives, the cracks can be reliably detected over a measuring length of up to 70 m and their change in width measured. They have a similarly good accuracy to conventional crack width sensors. The measurement system was verified under real conditions in the Tauern Tunnel with a one-year measurement campaign. The accuracies achieved were, for example, 0.035 mm (laboratory scale) and 0.15 mm (for real applications). Measurement layout and interval were derived based on potentially interesting crack phenomena. This will enable future crack detections even for areas that cannot be seen.

The evaluation can also be automated. With a self-developed method, the maximum crack widths occurring between epoch measurements can be determined. This method was submitted as a European patent in 2020 by AIT and TU Graz. The interrogator can now also be used to additionally record strain rates under dynamic loading distributed over the test object using low-cost optical fibers.

Measurement system of distributed fiber optic measurement. Length changes of the measuring fiber (optical waveguide) can be measured via interferences by means of an interrogator. The cable is sensor and line at the same time. With the interrogator, strains and now also strain rates can be measured under dynamic loading. © https://lunainc.com/product/odisi/

Laboratory tests within the FFG project RIBET with different fiber applications

![[Translate to English:] Faseroptische Messung](/fileadmin/mc/Transport_Technologies/TIT/Solutions/Solutions_untergeordnet_TIT/Interrogator/Faseroptische_Messung.jpg)

![[Translate to English:] Laborversuch](/fileadmin/mc/Transport_Technologies/TIT/Solutions/Solutions_untergeordnet_TIT/Interrogator/Laborversuch.jpg)