High-Temperature Heat Pumps: Efficient Process Heat for Industry

Industrial or high-temperature heat pumps are specifically designed for industrial applications that require high process heat levels, typically ranging from 80 to 200°C. They utilize environmental heat, waste heat, or geothermal energy, offering an energy-efficient and climate-friendly alternative to fossil fuels. These systems are particularly relevant for industries such as food processing, chemical production, and paper manufacturing, where high temperatures are essential for processes like drying, sterilization, and heating. High-temperature heat pumps contribute to reducing CO₂ emissions and play a key role in supporting the energy transition.

Development of Industrial and High-Temperature Heat Pumps – AIT, Your Leading Partner

As a leading institute for industrial heat pumps, the AIT Austrian Institute of Technology provides comprehensive services for integrating heat pumps into industrial processes. Our expertise includes analyzing and optimizing entire systems to develop customized solutions tailored to your specific requirements.

Our Services at a Glance:

- System Analysis and Optimization: We identify processes with heating and/or cooling demands and evaluate their optimization potential. This includes assessing the availability of (waste) heat sources and creating load profiles to maximize efficiency.

- Temperature Lift Assessment: Our experts analyze the required temperature lift and ensure it is suitable for the efficient operation of the heat pump.

- Utilization and Economic Feasibility Analysis: We assess the planned utilization of the heat pump and compare operating costs with existing systems to determine the most cost-effective solution.

- Planning and Implementation: Our team supports you in planning and implementing the heat pump solution, including integration into existing systems and considering potential retrofits or system upgrades.

With years of experimental experience in industrial heat pumps and high-temperature storage, combined with extensive knowledge in modeling and simulation of complete systems, AIT is your trusted partner in developing optimal solutions for your project.

Industrial Heat Pumps: Application Potential and Energy Savings

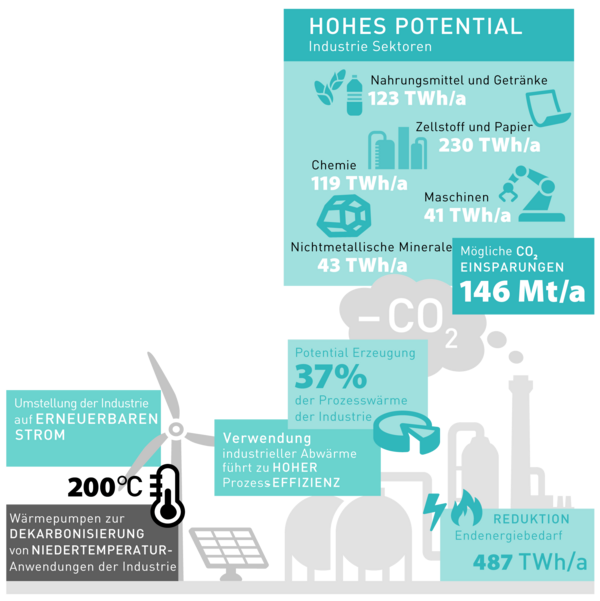

Recent advancements enable heat pumps to efficiently provide process heat up to 200°C. These systems could supply up to 222 TWh per year, covering approximately 11% of the process heat demand in European industries. This would result in an annual CO₂ reduction of around 51 million tons.

If heat pumps become widely established in the temperature range up to 200°C, they could additionally supply 508 TWh per year, covering another 26% of industrial process heat demand, leading to a further 95 million tons of CO₂ emissions saved annually.

In total, heat pumps have the potential to cover up to 730 TWh per year, or 37% of industrial process heat demand, contributing to a CO₂ reduction of approximately 146 million tons per year.

Industry-Specific Applications of Industrial Heat Pumps

The use of heat pumps operating at temperatures up to 200°C presents significant energy-saving potential across various industries:

- Pulp and paper industry: 230 TWh per year

- Food and beverage industry: 123 TWh per year

- Chemical industry: 119 TWh per year

- Non-metallic minerals sector: 43 TWh per year

- Mechanical engineering: 41 TWh per year

Industrial Waste Heat & Energy-Efficient Electrification of Industrial Process Heat

Industrial heat pumps enable an energy-efficient electrification of industrial process heat by utilizing existing heat sources. They convert industrial waste heat, which would otherwise be lost, into usable high-temperature heat, reducing energy costs and improving the CO₂ footprint. Additionally, they can extract heat from deep geothermal energy and ambient air, providing heating energy independently of fossil fuels. Through this electric operation, industrial processes can be decarbonized, contributing to sustainability, stabilizing energy consumption, and unlocking efficiency potential.

Today’s heat pumps cover all temperature ranges from 50 to 200°C and power outputs from 20 kW up to over 20 MW. This makes nearly all applications within the respective temperature range possible. If there is a simultaneous demand for both heating and cooling, the economic feasibility of a heat pump can be significantly increased, as efficiency improves. At the same time, investment costs decrease, since no separate cooling units are required. Typical examples in the food industry include dairies. They require both chilled water and low-temperature heat. Additionally, wastewater must be cooled before being discharged into water bodies.

Power2Heat: Using Renewable Energy for Industrial Heat Pumps

The use of electricity from renewable energy sources for industrial heat pumps is a key lever for achieving sustainable heat supply in the industrial sector. This combination enables the generation of climate-friendly and low-emission process heat.

By utilizing green electricity, the necessary heat for industrial applications such as drying and heating processes can be produced without relying on fossil fuels. This not only reduces CO₂ emissions but also decreases dependency on fluctuating raw material prices, contributing to long-term stability and efficiency.