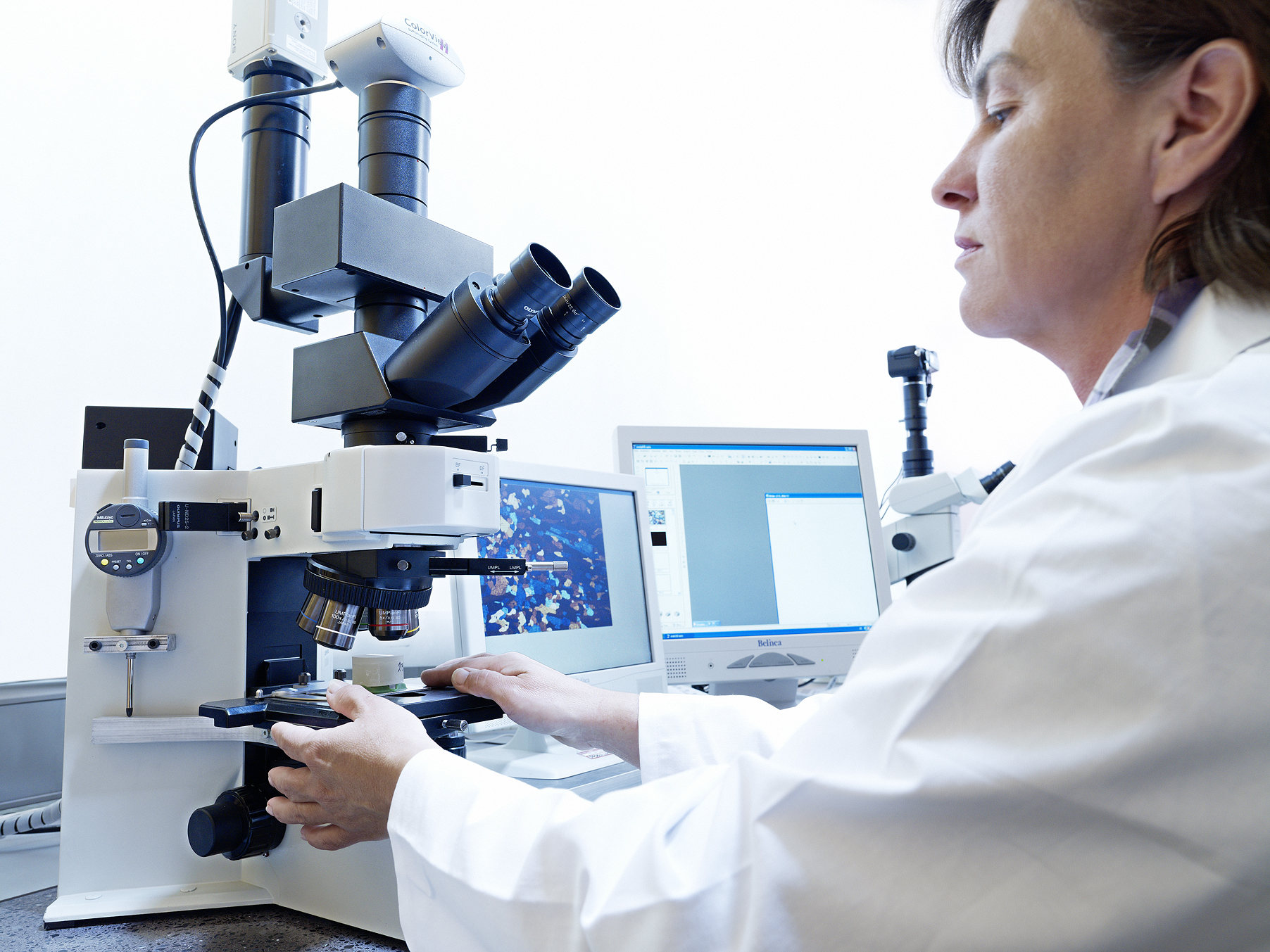

Macro- and Microscopic Microstructure Examinations

-

In-depth analyzes of the materials and their respective process histories

-

Identification of problems in the manufacturing process, e.g. with respect to casting and forming parameters, heat treatments or the input of foreign material

Our Services

- Preparation and documentation of sections of metallic materials and composite material samples

- Section analysis according to test standard as well as beyond that so as to be tailored to the respective Task

- Micromechanical analysis (down to individual phases) by means of Vickers microhardness measurement acc. to EN 6507-1

- Quantitative determination of particle and cell sizes acc. to ASTM E112

- Documentation and analysis of samples from forming and heat treatment tests

Technical Data

| Test Procedure | Performance Parameters | Application |

|---|---|---|

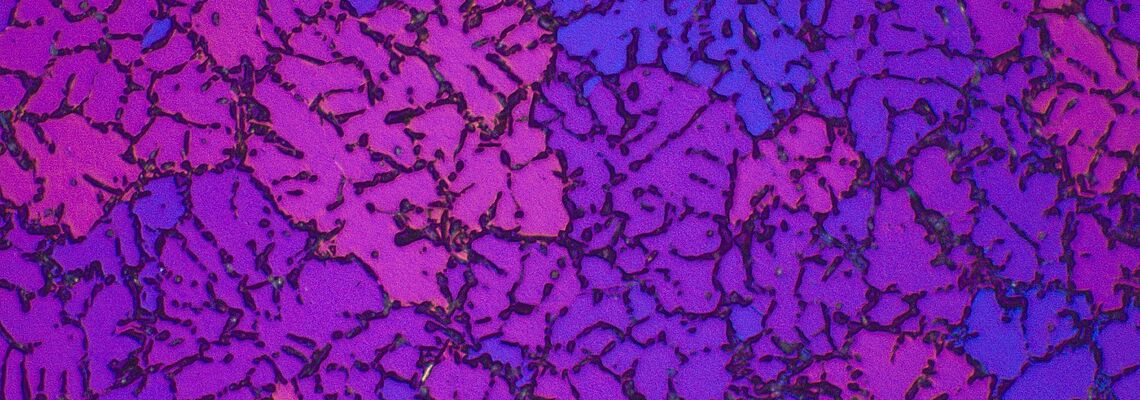

| Microstructure characterisation |

|

Optimisation of casting parameters Evaluation of element influences of complex material composites, weld seams, etc.. |

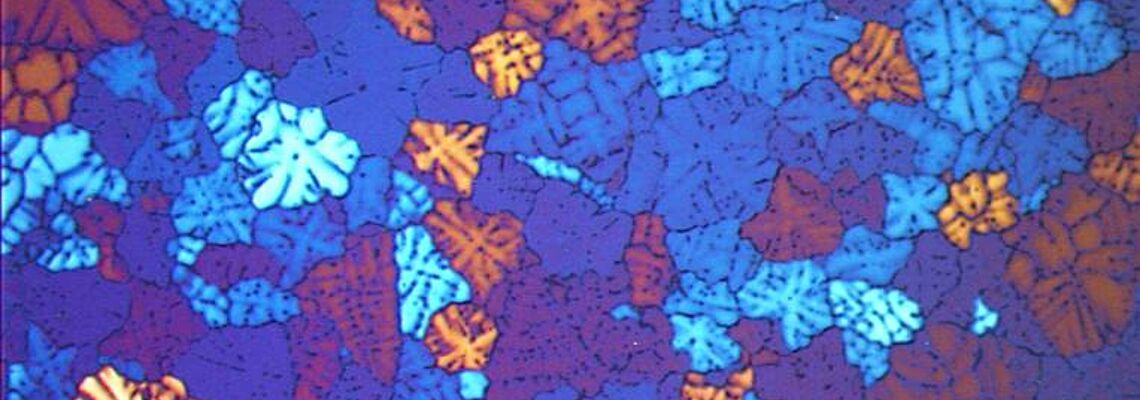

| Particle size measurement |

|

Influence of particle refining or cooling rates

Microstructural homogeneity |

| Microhardness measurement |

|

Effect of heat treatment parameters Mechanical analysis of individual phases |

| Topology measurement | Confocal white light microscopy

|

Preparation of surface profiles

3D documentation of surface qualities Abrasion depths, etc. |

| Fracture surface analysis | Stereomicroscopy, SE-REM analysis |

Analysis of fracture types structural and chemical analysis of inclusions |

![[Translate to English:] LKR Standort](/fileadmin/_processed_/1/f/csm_AIT_LKR_Standort_4fe61c1df0.jpg)