Fracture mechanics and fatique behaviour

-

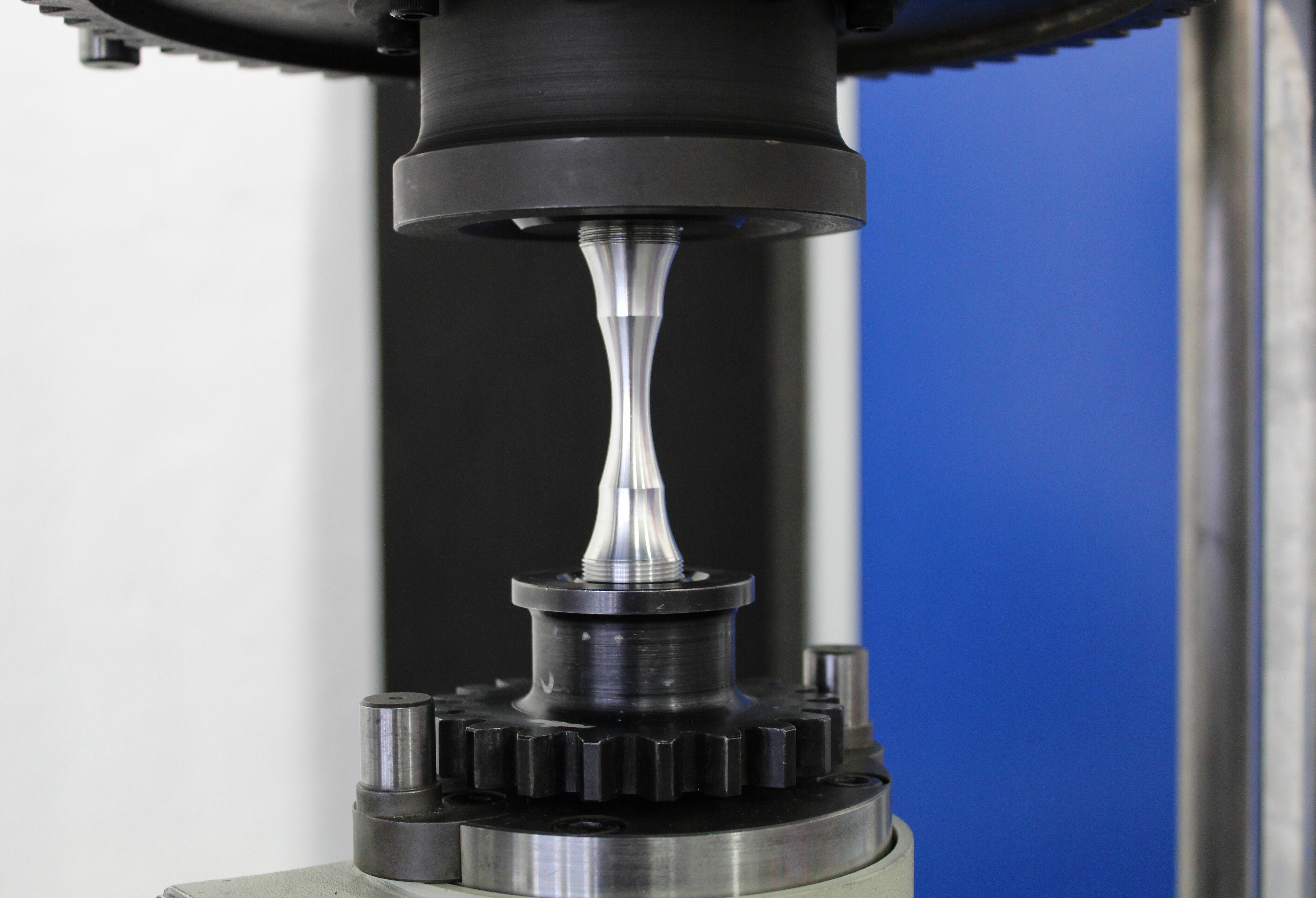

Measurement of high cycle and long life fatigue strength (HCF & LLF)

-

Fatigue testig with resonance frequency to simulate material behaviour and failure in real life application

-

High testing frequency (80 Hz)

-

Flexibility regarding sample geometry, load condition, material

Pendulum machine

Our services

- Fatigue testing and Wöhler curves of standard and special samples, components

- Short test duration thanks to resonator testing machine (RUMUL Testronic)

- Detection of hardening and softening behaviour during the individual tests

- Tests at room and increased temperature

- Very small (<1 kN) to very large loads, at freely selectable load levels (tension/compression)

Technical Data

| Test Procedure | Performance Parameters | Application |

|---|---|---|

| Fatigue test in the range of high cycle and long life fatigue |

| Creation of Wöhler curves, release dates for newly developed alloys |

| Fatigue testing at elevated temperature |

| Materials at real operating temperatures |

![[Translate to English:] LKR Standort](/fileadmin/_processed_/1/f/csm_AIT_LKR_Standort_4fe61c1df0.jpg)