Testing of Electric Drivetrains and Power Electronics

The AIT Austrian Institute of Technology offers excellent research and validation infrastructure to ensure that your powertrain development process meets the market requirements. With our testbed solutions we enable you to increase quality, reduce costs and the time-to-market. We offer one-stop solutions.

Our Services

HiL – Hardware in the Loop

Power electronic components up to complete electrical drive trains can be tested. The test bench responds to the system based on (vehicle) model and the actual performance of the system. The services include the following aspects:

- Customer specific drive cycles or power cycles

- Customer specific Simulink models

- Integration of customer ECUs (Electronic Control Units)

- Testing with the real traction battery or DC-power supplies with a battery model

- Temperature- and flow-controlled cooling

- Centralized and time-synchronous datalogging

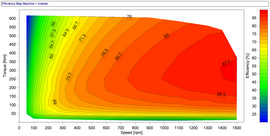

Efficiency Maps

The automated measurement of efficiency maps at system level including the data acquisition of electrical, mechanical and thermal values:

- Freely definable measuring pattern

- Measurement of overload working points

- Measurement under defined thermal conditions

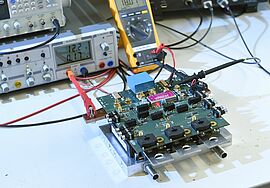

Power Electronics

Testing and validation of power electronics for electric mobility on component level or within the system:

- Thermal and electrical validation of semiconductor modules

- Optimization of commutation by means of own test converter

- Measurement of switching losses/conduction losses

Testbench Control

Our in-house control program enables the centralized and time-synchronized acquisition, storage and visualization of measurement data. It enables the simulation of user-defined performance profiles and driving cycles as well as the definition of semi or fully automatic test procedures. The following interfaces are available for the integration of customer-specific drive systems:

- Analog input/output

- Digital input/output

- Serial interfaces RS232/RS485

- CAN (Controller Area Network)

Properties

Power Supplies

- Sinusoidal: 5 to 180 Hz, up to 5000 V, 400 kW

- Direct current: up to 1000 V, ±400 kW

- Frequency Inverter: Control of asynchronous and synchronous permanent excited electric machines up to 160 kW

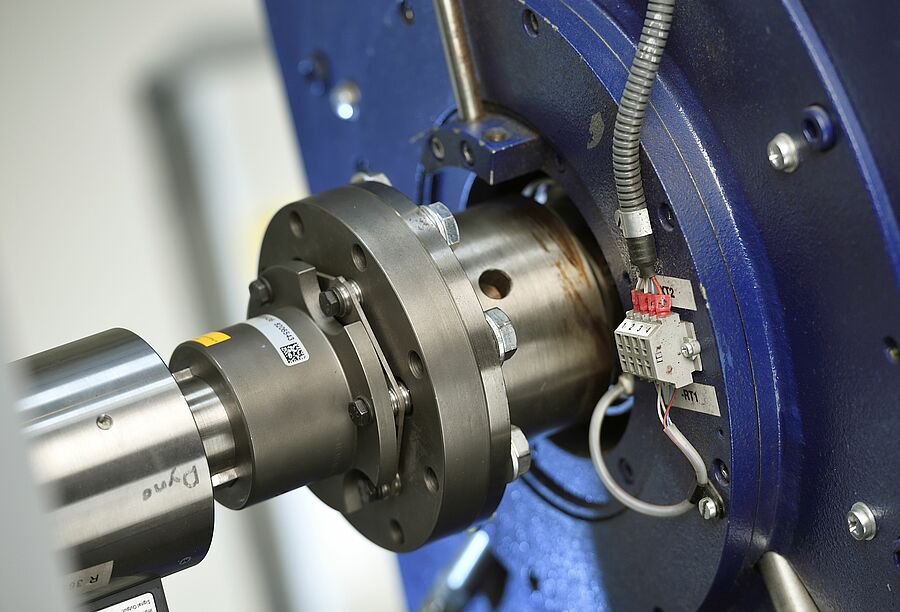

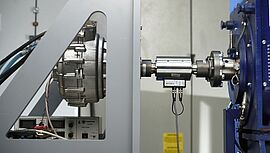

Drive Testbench

- Highly dynamic testbench 100 kW, 22000 U/min

- Highly dynamic testbench 120 kW, 8000 U/min

- Testbench 280 kW bis 3500 U/min

The highly dynamic testbenches are applicable for "Hardware-in-the-Loop"-control with a maximum scan-rate of 1 kHz.

Measurement Equipment/Data Acquisition

- Power analyzer for RMS values split in fundamentals and harmonics

- Voltage and current waveforms with a max. scan-rate of 5 MHz

- High precision torque sensors from 0.1Nm up to 2000 Nm, max. scan rate 10KHz

- Temperatures; thermocouples, PT100, KTY, etc.

- Implementation of customer specific sensors for various signals

- Controlled liquid cooling circuits

![LET_Propulsion-Technologies_Antriebslabor [Translate to English:] Image Bild](/fileadmin/_processed_/d/4/csm_EDT_Antriebslabor_065_8e51eac36f.jpg)

![[Translate to English:] Image Bild](/fileadmin/_processed_/2/e/csm_Drive_Lab_web_06753110f4.jpg)