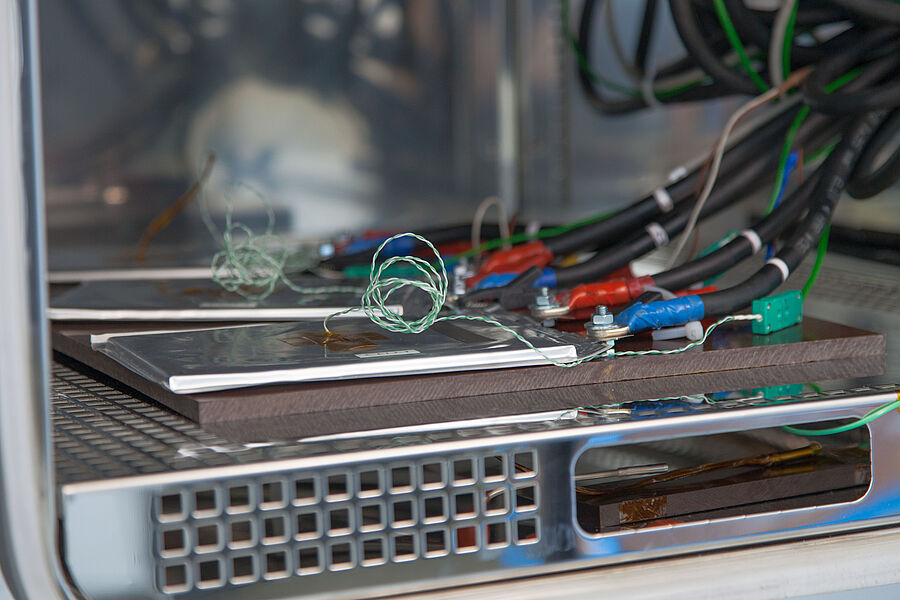

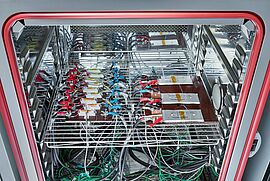

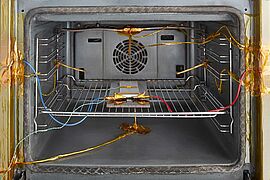

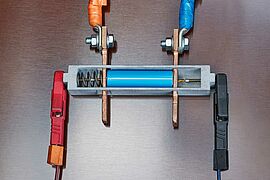

In the battery test laboratory, batteries are examined in detail at cell, module and system level. This includes electrical tests, as well as an evaluation of safety through misuse tests.

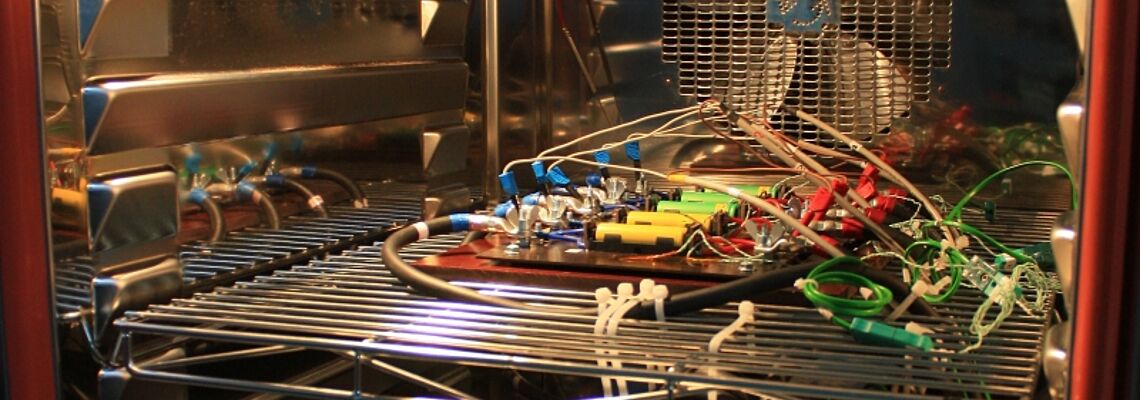

Electrical tests

- Support in selection of cell technology

- Function checks

- Characterization of batteries

- Simulation of driving cycles

- Durability studies

- Calendar aging

- Cyclic aging

- Investigation of the influences of different environmental conditions

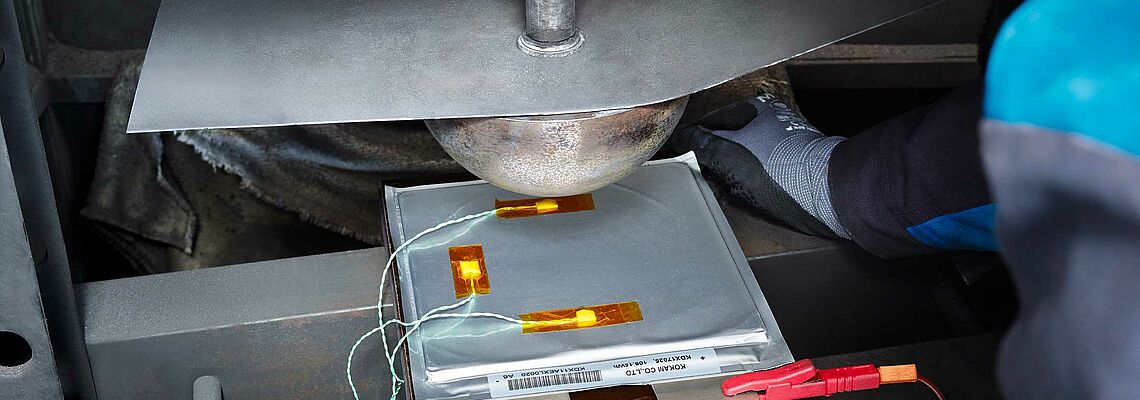

Safety tests

- Thermal

- Thermal stability

- Elevated temperature storage

- Mechanical

- Internal short circuit

- Controlled crush

- Drop

- Electrical

- Overcharge

- External short circuit

- Rapid charge / discharge