Simulation of the microstructure of aluminium during solidification

During the solidification of aluminium alloys, a microstructure forms in the solid phase of the material. The microstructure is decisive for the quality and mechanical properties of a material. In general, it is desirable to achieve a fine and homogeneous microstructure.

The formation of the microstructure is strongly dependent on the type of process and the associated process parameters. The influence of these parameters shall be systematically investigated in order to finally achieve a desired microstructure by dynamic process parameter adaptation.

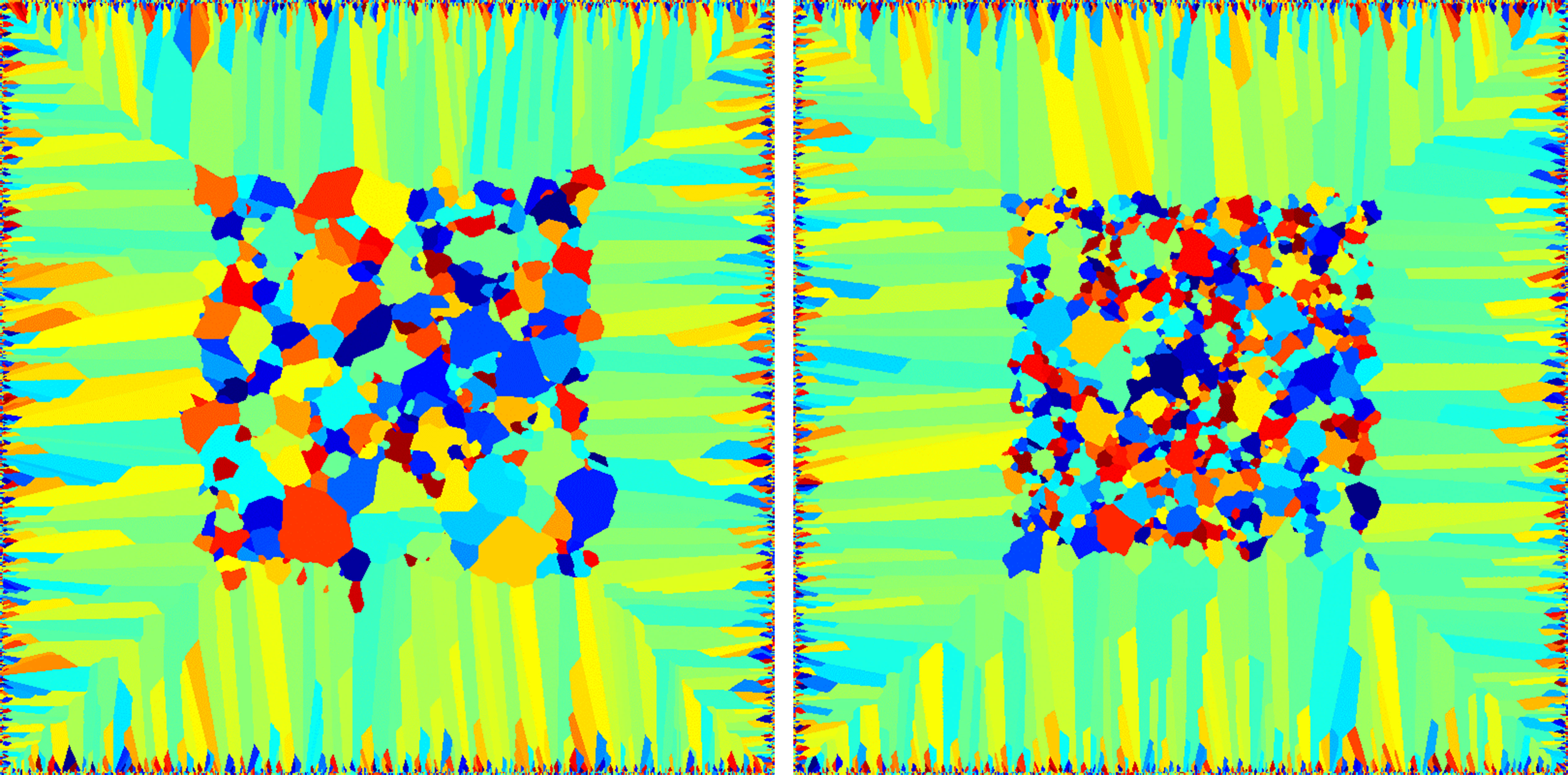

Process-dependent microstructure formation with a higher cooling rate in the right figure, which in this case leads to a finer microstructure in the middle area.

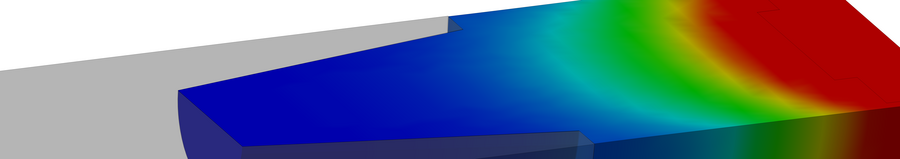

The main focus of the current work is the development of a numerical framework to efficiently perform such multi-scale simulations. Thus, especially dendritic grain growth is to be considered, taking into account local solute concentration, fluid flow and convective grain transport. This approach will be used in the future for the investigation of industrial problems.

![[Translate to English:] LKR Standort](/fileadmin/_processed_/1/f/csm_AIT_LKR_Standort_4fe61c1df0.jpg)