Simulation of cooling mechanisms including phase transitions of the cooling fluid for the production of semi-finished products

Solidification processes play an essential role in the production of light metal semi-finished products. To ensure quality and productivity, defined cooling conditions are necessary for solidification. Unstable cooling conditions can lead to hot or cold cracking during the solidification of aluminium alloys.

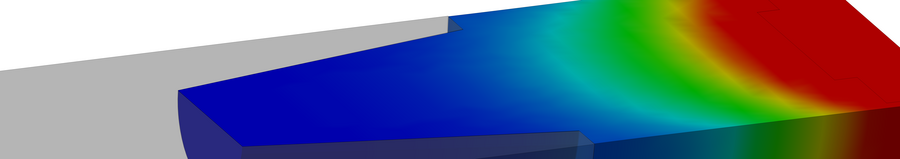

Numerical investigations of cooling systems are carried out at the LKR Leichtmetallkompetenzentrum Ranshofen. For this purpose, methods of numerical fluid mechanics (CFD) are applied. The focus is on the investigation of water-based cooling systems in which water is applied to the solidified surface of the semi-finished product. The high temperature at the surface causes a highly dynamic phase transition from water to steam. This leads to specific phenomena, such as the Leidenfrost effect. Capturing these effects is a great challenge in simulation. For this purpose, special models are developed at the LKR, which focus on the application for industrial tasks.

![[Translate to English:] LKR Standort](/fileadmin/_processed_/1/f/csm_AIT_LKR_Standort_4fe61c1df0.jpg)