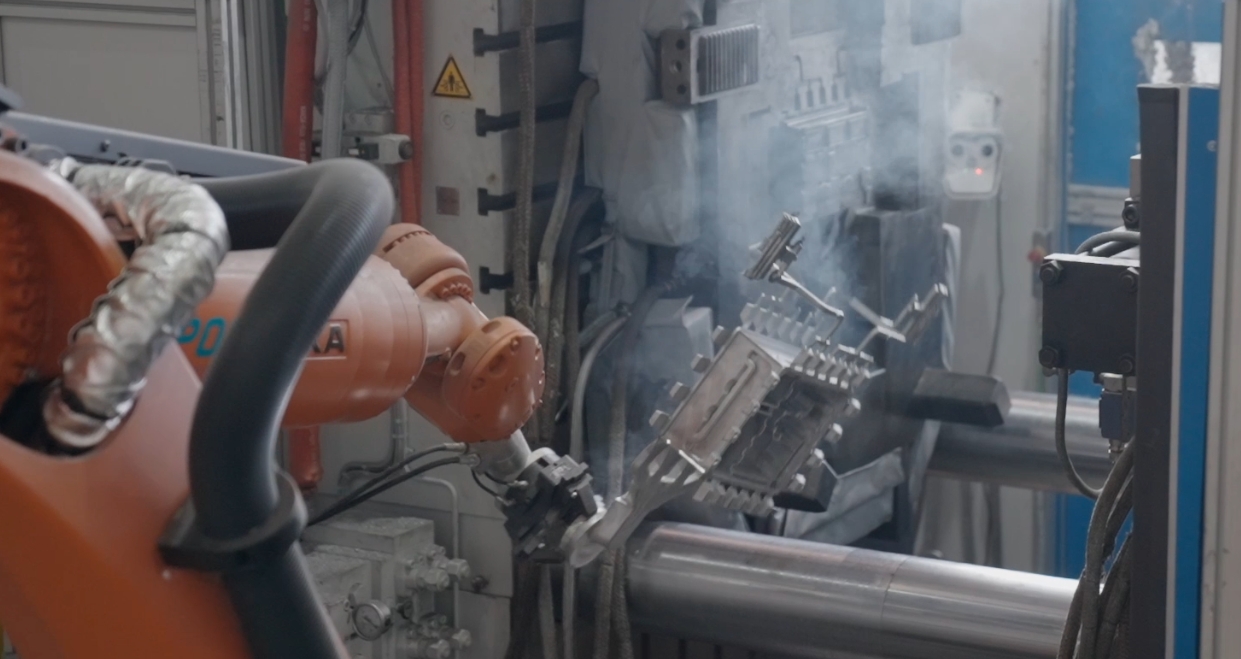

850 - 9200 t clamping force

From incoming goods to outgoing goods

The know-how of the employees and the availability of the machines is the basement for the quality and efficiency of an aluminium and magnesium die-casting production. This means that correct and sensible designs are the basis for process-reliable production. Resources for engineering and product development are usually very limited. However, these factors have a considerable influence on casting quality, tool life, testing effort and rework costs. A detailed consideration of the influencing variables saves costs and time in numerous cases.

Module 1:

Process input variables

Evaluation and analysis

This module handles the numerical framework conditions based on the theoretical principles of a mould filling simulation: What can be simulated - what cannot? We mirror production framework conditions into the simulation and evaluate them according to how they can be influenced. Your employees learn in which way these framework conditions have an influence, for example, on the constructive design of the component.

Process development

Process and mould design

This module covers some short calculations, which concern the necessary requirements such as the periphery in the production and the casting system design. Another important topic is the selection of materials and the associated production requirements. Here we develop solutions and remedial measures in the team and on components from your portfolio, which are then put into practice after the training.

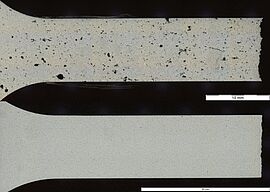

Module 3: Process evaluation

Component-related process optimisation

This module concludes the theoretical part of a product development and manufacturing process and is dedicated exclusively to practice-oriented tasks. Questions about the characteristics and definition of defects as well as their localisation possibilities in simulation and serial production are answered here. Last but not least, we develop approaches to solutions and sustainable elimination measures: The participants now independently implement sustainable optimisations based on the results from casting simulation and defect analysis into serial production.

General Information

Participants

Employees from the areas of casting production, machining, technical sales, process and product development, quality assurance and work preparation.

Number of participants

Maximum of ten participants per module

Training duration

Single Module 1: 1 day (950€/person)

Single Module 2: 2 days (2.200€/person)

Single Module 3: 2 days (2.600€/person)

Booking complete package: 5 days (4.900€/person)

Cost saving complete package to single booking 850€ per person

Individual training modules: by arrangement

CONTACT

GIULIA SCAMPONE

AIT Austrian Institute of Technology /

LKR Leichtmetallkompetenzzentrum Ranshofen

Tel +43 664 78050899

giulia.scampone(at)ait.ac.at