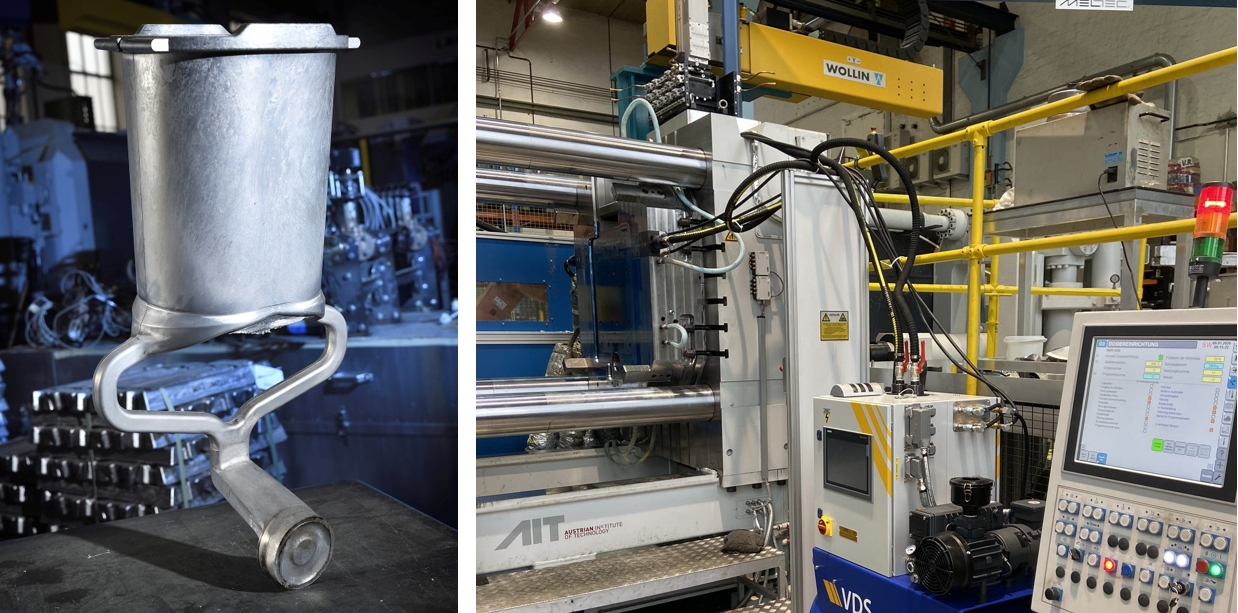

Fully automated test facility on an industrial scale for process and material development

Our services

- Process and customer specific modification of aluminum alloys

- Development of flame resistant magnesium alloys

- Testing laboratory for microstructure, material and process characterization

- Component development with a focus on mechanical properties and weight

- Development of temperature control concepts

- Energy management of the die casting cell with a focus on the mould

- Novaflow & Solid filling and solidification simulation

- FEM component simulation

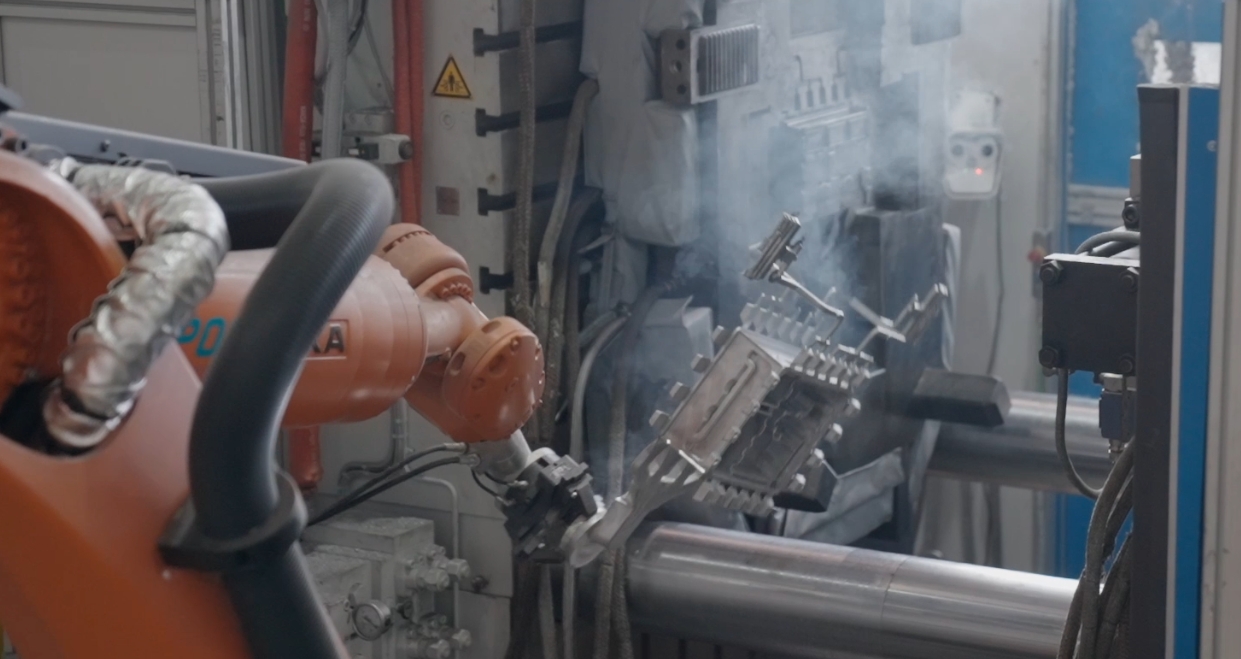

- Prototypes and small series

- Training in the field of die casting and its peripherals:

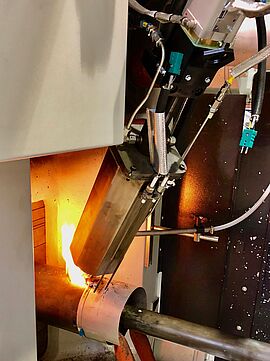

Cold chamber die casting production 850-9200 T clamping force

Technical Data

| manufacturer |

| |

| locking unit |

| |

| casting unit |

| |

| dosing unit |

| |

| crucible furnace |

| |

| peripherals |

|

![[Translate to English:] LKR Standort](/fileadmin/_processed_/1/f/csm_AIT_LKR_Standort_4fe61c1df0.jpg)