AI5Production supports Austrian manufacturing companies with up to 2,999 employees with their digitalization and offers a comprehensive range of services. As part of the European Digital Innovation Hubs (EDIH) initiative, AI5Production acts as a central point of contact to make companies fit for the challenges of digital transformation. Services include access to research infrastructure and expertise to support digital transformation efforts, as well as assistance in securing funding for investments.

In close cooperation with the hub's partners, companies develop individual research and development approaches. AI5Production provides access to infrastructure for tests, measurements and test series as well as the development of new products and processes. This offering is complemented by a diverse training programme that includes courses, webinars and workshops on relevant topics relating to digitalization and Industry 5.0.

The project consortium includes 16 Austrian companies and both university and non-university research institutions based in Vienna and Upper Austria. Project coordination is managed by the Pilot Factory Industry 4.0 at TU Wien. Alongside TU Wien, University of Vienna, and JKU, other partners include AIT, Profactor, as well as several competence centers and industry partners.

The AIT Austrian Institute of Technology offers bundled expertise from five Centers

Helmut Schrom-Feiertag, Center for Technology Experience, emphasizes the human-centric focus: “People should always be at the heart of technology development and innovation. This is precisely why it is important to support SMEs in terms of Industry 5.0 - sustainable, resilient, human-centered – and human-centered AI on their path to digital transformation in the best possible way and, above all, from a user-centric technology experience perspective.”

Mario Drobics, Center for Digital Safety & Security, underlines the importance of key digital topics such as artificial intelligence and cyber security: “AI5Production enables us to support SMEs in the central aspects of digitalization – from AI and data ecosystems to cyber security – and thus lay the foundation for new business models in companies.”

The Center for Energy under the coordination of Gerhard Zucker, is focusing on the sustainable digitalization of the built environment: “As part of the DRIVE-THRU test-before-invest programme, the Center for Energy is contributing its expertise in the field of digital resilience and sustainability for the built environment. By developing an open database for technical building equipment (TBE), we are supporting the optimization of digital data consistency in TBE and contributing to the standardization and long-term digitalization of the industry.”

The LKR Leichtmetallkompetenzzentrum Ranshofen as part of the Center for Transport Technologies also contributes its expertise in the field of metal processing, as Gerald Prantl explains: “As part of Test-before-Invest projects, the LKR specifically uses the opportunity to establish contacts with companies from various areas of metal processing and support them in their digitalization projects. This enables the LKR to gain valuable insights into the daily challenges faced by its partners and at the same time to contribute and further develop its expertise in the research field of digitalization. AI5Production also provides the LKR with an important basis for initiating exciting follow-up projects.”

The Center for Vision, Automation & Control supports and accompanies industry in its digital transformation. The focus is on the protection of people and the environment, as well as the careful use of resources. Julia Hofstätter, AIT project manager for AI5Production and at the Center for Vision, Automation & Control, sums it up: “As part of AI5Production, we support companies in increasing their level of digital maturity through targeted technological developments and sustainably securing their competitiveness in an increasingly digital market environment - and thus paving the way to an innovative future.”

Visit us at

https://ai5production.at/

LinkedIn: EIDH AI5Production

Co-funded by the European Union and FFG

Test Before Invest Projects at AIT

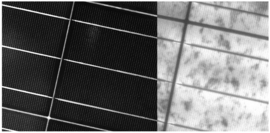

Re-use of Solar Modules

In collaboration with 2nd Cycle FlexCo, a green tech start-up company from Lower Austria, the AIT Center for Vision, Automation & Control, has successfully tested an optical inspection method for the characterisation of used solar modules for the purpose of reuse/repair/recycling.

Increasing the efficiency of TIG & plasma welding inverters

The AIT Center for Vision, Automation & Control and SBI GmbH, a leading high-tech company based in Ziersdorf, Lower Austria, are working on a feasibility study to develop an energy-efficient welding inverter.

Partial automation of a vacuum dosage system

At the AIT's LKR Leichtmetallkompetenzzentrum Ranshofen GmbH die-casting test facility, the vacuum dosing system from Meltec Industrieofenbau GmBH was equipped with independent temperature monitoring and control, tested and successfully validated. „Straightforward preparation and great results as part of the Ai5production - the smooth collaboration and short lead time have contributed significantly to the further development of our product." Angela Harrison, Sales Manager, Meltec Industrieofenbau.

BIM-based workflows for sustainable buildings

Together with the AIT Center for Energy, BELIMO Automation Handelsgesellschaft m.b.H. has developed a BIM-based workflow prototype. It improves data consistency and integrates life cycle assessments and material reuse strategies into the design process for building services equipment.

ALLEX: LLM-based knowledge database

As part of the EDIH AI5production the LKR Leichtmetallkompetenzzentrum Ranshofen of the AIT together with the Austrian tooling expert ALPEX Technologies GmbH, has launched the project ALLEX - Advanced Language Learning for Engineering Excellence in 2025. The aim is to develop an LLM-based knowledge database that optimises production processes and improves knowledge transfer in SMEs.