Our services

- Selection of suitable sensor technology for your application

- Faster process development and optimization

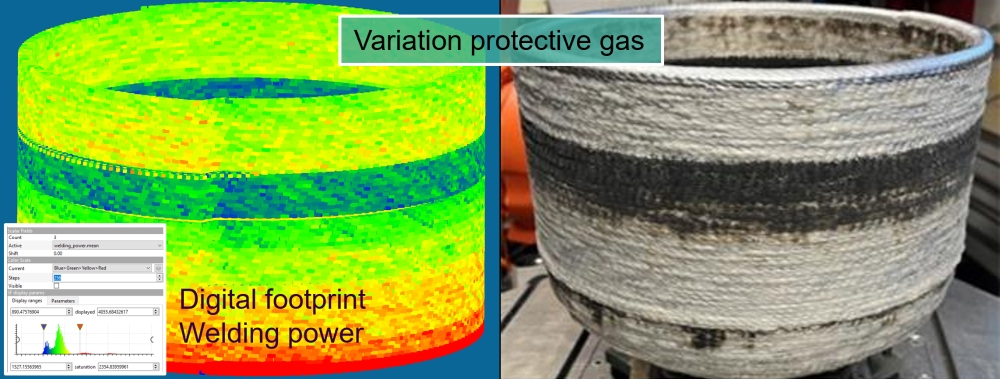

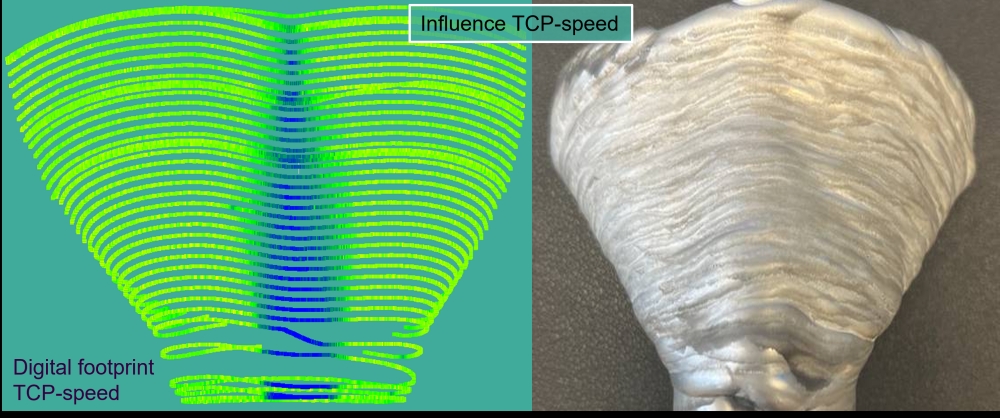

- Documentation of the construction process

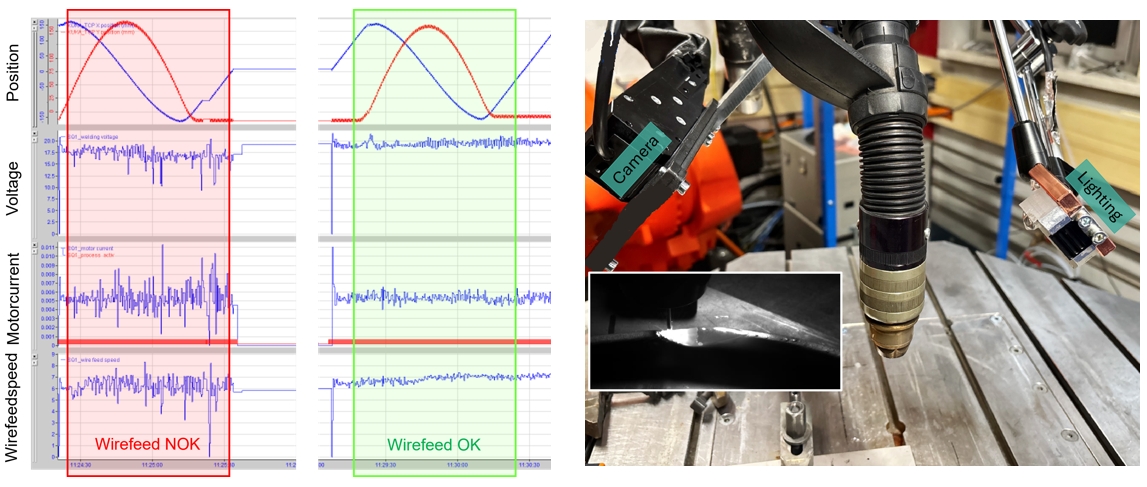

- Quality control: detection of anomalies

- Immediate system shutdown in the event of process irregularities

- Predictive maintenance

- Process control/automation

- Creation of a digital footprint

- Basis for ML/AI and AR/VR-based advisory systems for operators and service personnel

Possibilities

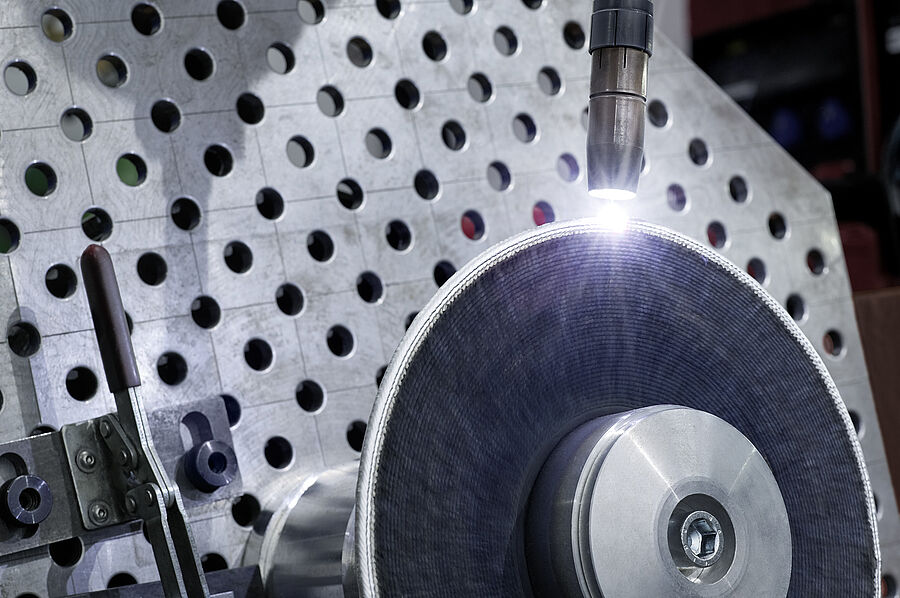

Fully digitized WAM laboratory

- 6-axis robot and 2-axis rotary tilt table (KUKA/ABB) and glovebox

- 6-component inline gas mixer

- Component dimensions up to 1,500 mm

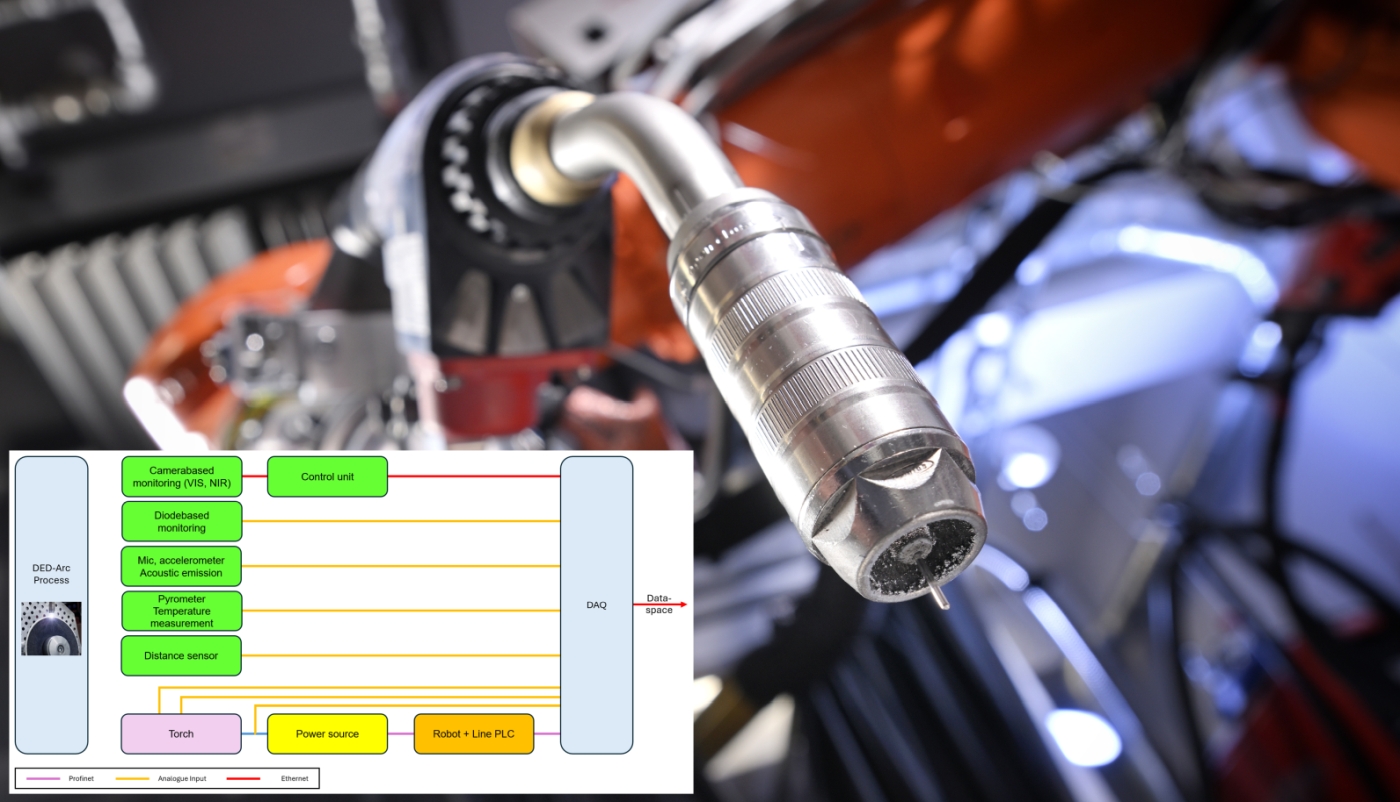

Data acquisition

- Robot (kinematics)

- Power source (current, voltage, wire feed, etc.)

- Energy data of the system (LCA analysis)

- Process parameters

- Sensor data

- Camera-based: e.g. Fronius ArcView2

- Diode-based:

- plasmo® fastprocessobserver (nLIGHT)

- Fast current, voltage, and wire feed measurement (LKR)

- Acoustic: structure-borne sound, microphones

- Thermal: pyrometer, PT100

- Distance sensors: 1D and 3D

Technical specifications

Data acquisition

- Number of digital I/O 24

- Number of analog I/O 32

- Encoder inputs 4

- Data rate analog/digital EA 40kHz

- Fieldbus monitor Profinet Yes

- Data rate fieldbus 100Hz

- Video capture Yes

- Latency times 2-8ms

- Time synchronization 10µs

- Process control option Yes

- Data recording Yes

Sensor specification

- Voltage/analog EA 0-20kHz

- Welding current 0-1,000A 0-10kHz

- Microphone 20Hz-20kHz

- Structure-borne sound 0.2Hz-15kHz

- Pyrometer 100/600°C approx. 1kHz

- Distance sensor 100-600 mm up to 8 kHz

- Encoder up to 2 MHz

- ArcView2 camera 1024x768@40fps

- Temp. measurement PT100 On request

- Dust measurement On request

- Energy measurement (LCA) 1 s