Precision for the highest quality

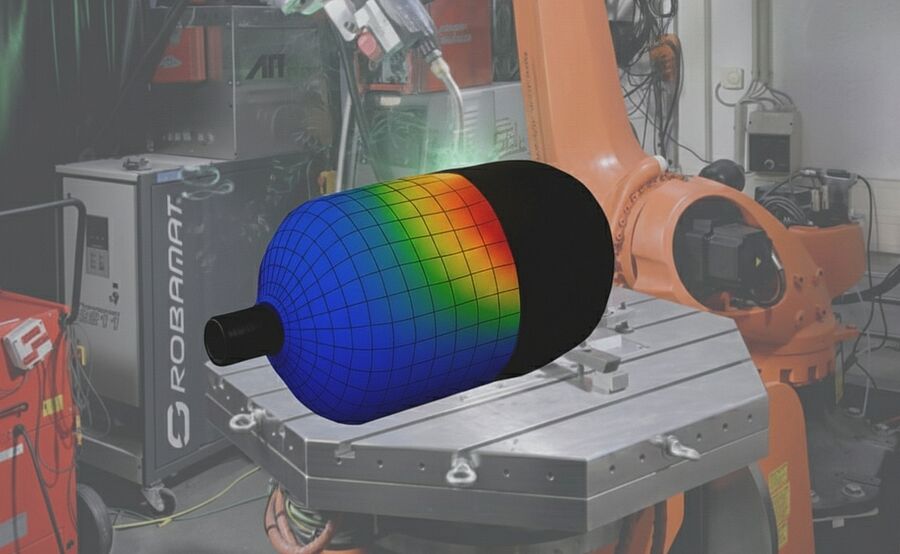

Continuous direct chill casting is a key industrial process for producing high-quality aluminum alloy billets. Ensuring optimal control of process parameters and cooling conditions is essential for maintaining productivity and achieving superior product quality. In sensitive configurations, even minor deviations from ideal conditions can result in defects such as cracks, material waste, or costly production downtimes.

At LKR, we are actively engaged in advancing the understanding and optimization of continuous casting processes – both in vertical and horizontal configurations – through a combination of experimental research and cutting-edge digital simulation tools.

Our simulation framework integrates high-fidelity thermo-mechanical and fluid dynamics models, enabling a comprehensive representation of the casting process from initial mold filling to steady-state operation.

We apply specialized methodologies to capture complex interface phenomena, that arise when cooling water contacts the high-temperature surface of freshly solidified metal. This knowledge is embedded in our current simulation frameworks, enabling more accurate predictions of the surface thermal behavior – a crucial factor for quality assurance.

Digital twinsfor casting processes

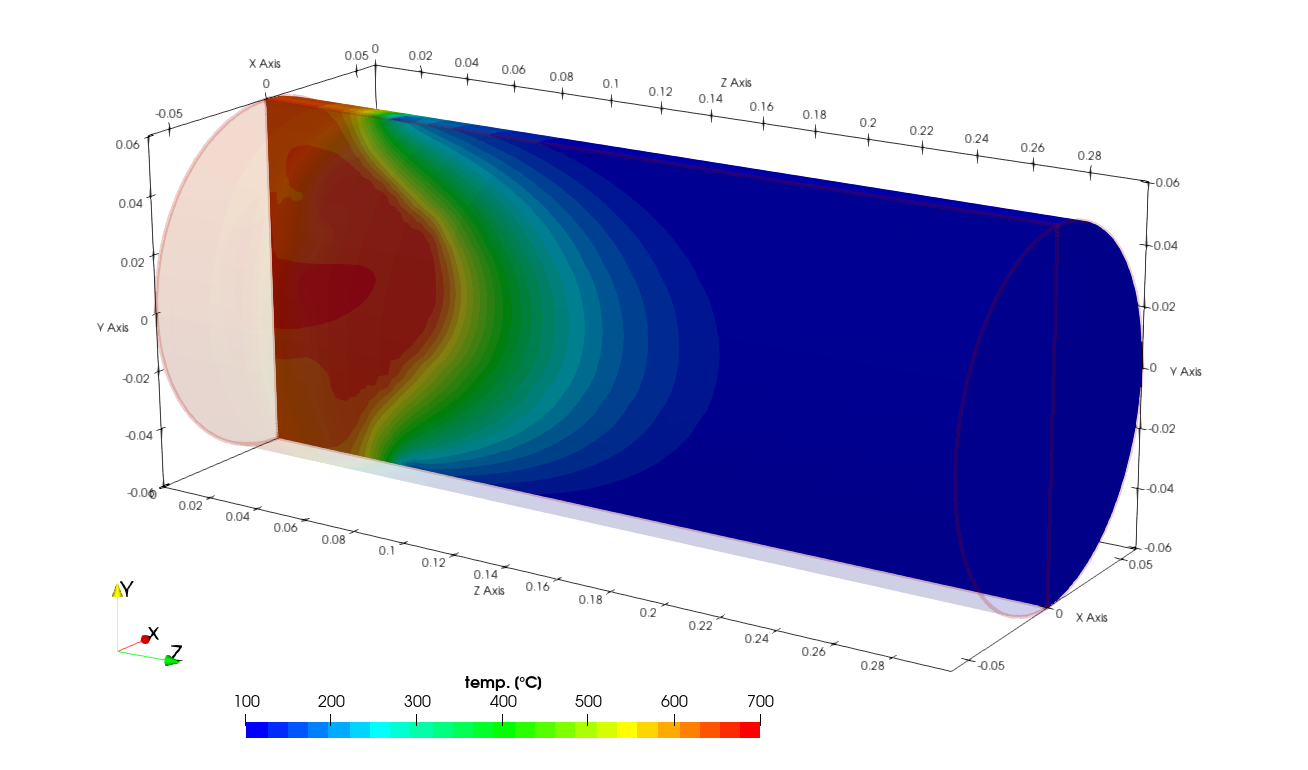

Using the FEM solver LS-DYNA®, we can analyze deformation behavior, internal strain evolution, and residual stress distribution at the end of the casting process.

From high fidelity to real-time

Through OpenFOAM®-based open-source CFD tools, we can investigate complex fluid phenomena such as multiphase flow, convective heat transfer or even macrosegregation of alloying elements –providing deep insights into the physics driving process performance.

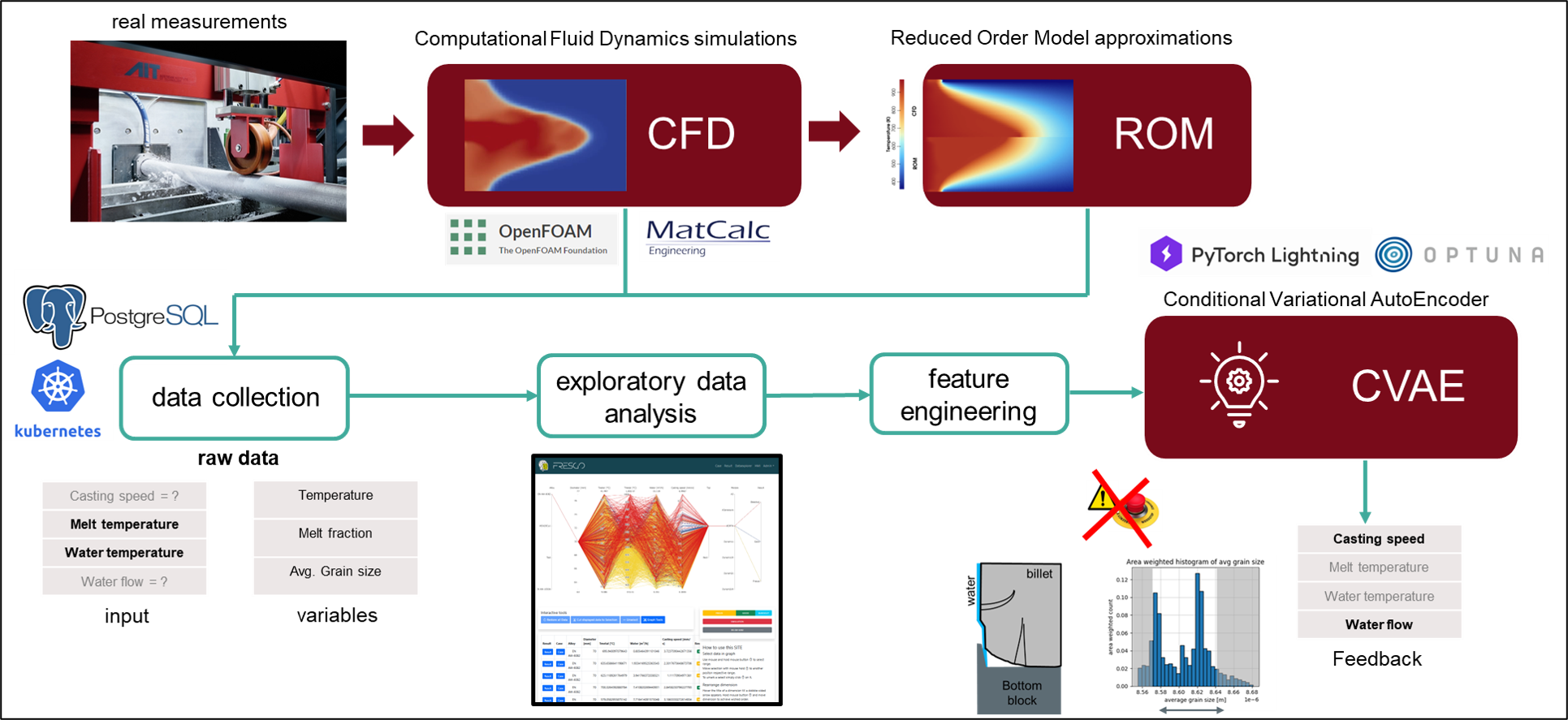

Beyond these physics-based models, we are also developing reduced-order models and data-driven approaches that deliver near real-time predictions. These models are designed to support decision-making in industrial environments, offering practical tools for process monitoring and optimization.

Explore our ongoing projects such as opt1mus and AI4SimProd to learn more about how we are integrating AI and simulation for smarter production systems.

Workflow for creating reduced numerical models

![[Translate to English:] LKR Standort](/fileadmin/_processed_/1/f/csm_AIT_LKR_Standort_4fe61c1df0.jpg)