Accuracy Starts with the Right Model

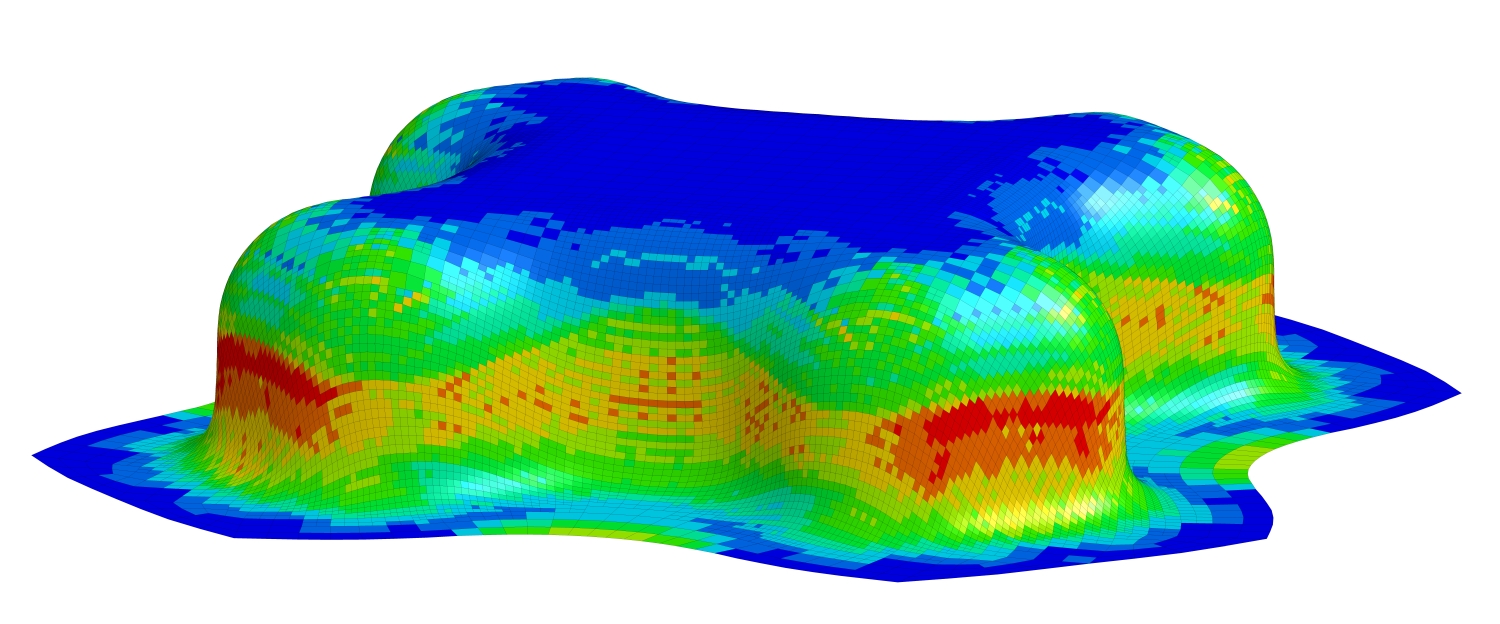

The Finite Element Method (FEM) is one of the most widely used numerical tools for evaluating the performance and functionality of components. However, the accuracy of any FE simulation strongly depends on the precise characterization of material behavior—such as plasticity, anisotropy, and fracture mechanisms.

At LKR, we develop advanced material models for aluminum alloys using a combined experimental and numerical approach. Our goal is to capture the complex mechanical response of bulk and sheet metal materials under realistic loading conditions and integrate these models into state-of-the-art simulation frameworks.

Comprehensive Experimental Testing

Our material characterization program includes:

- Uniaxial tensile tests

- Shear tests

- Plane strain tests

- Biaxial tensile tests

These tests provide the foundation for identifying constitutive parameters and calibrating models that accurately predict forming limits, springback, and failure behavior. LKR uses Valimat Software from 4a engineering in combination with the LINOVIS® testing system.

From Experiments to Predictive Models

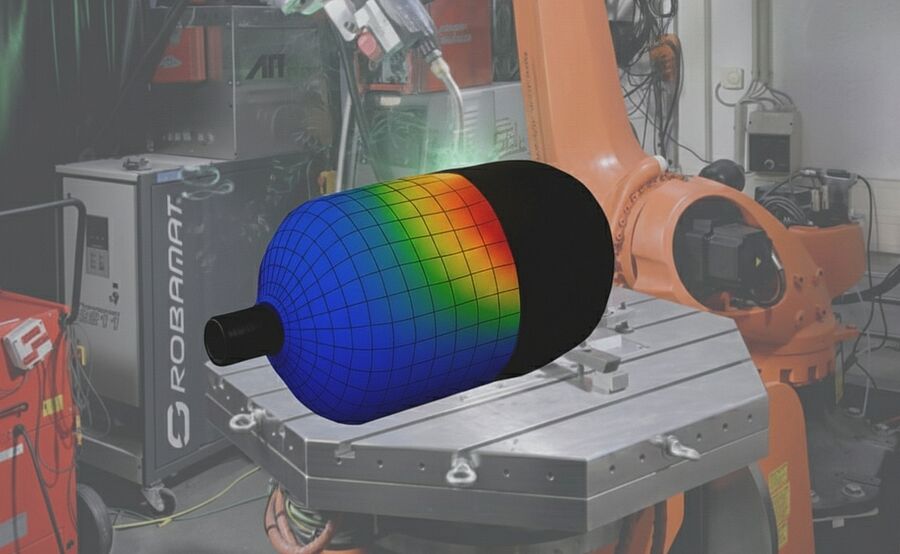

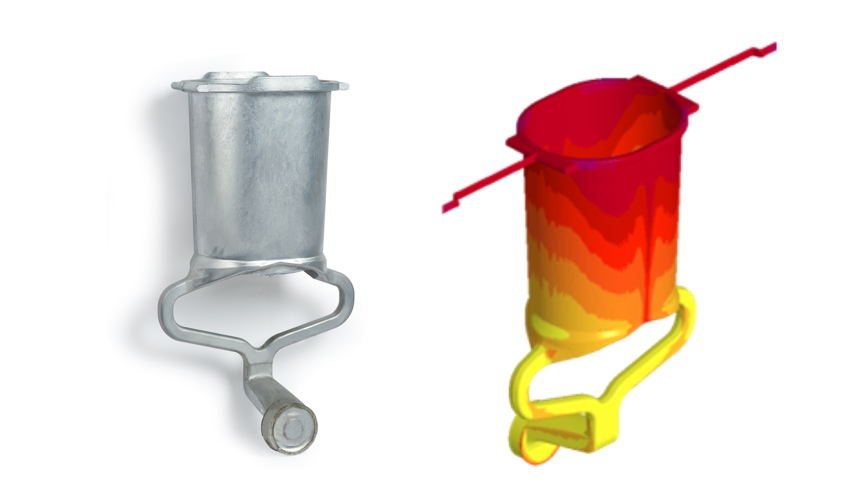

Using advanced inverse modeling techniques, we translate experimental data into robust constitutive models for FEM-based process simulations. This enables reliable predictions for a wide range of forming and manufacturing processes, including casting, extrusion, wire additive manufacturing, and deep drawing.

By combining high-quality experimental data with cutting-edge numerical methods, we ensure that our simulations deliver the precision needed for process optimization and lightweight design.

![[Translate to English:] LKR Standort](/fileadmin/_processed_/1/f/csm_AIT_LKR_Standort_4fe61c1df0.jpg)