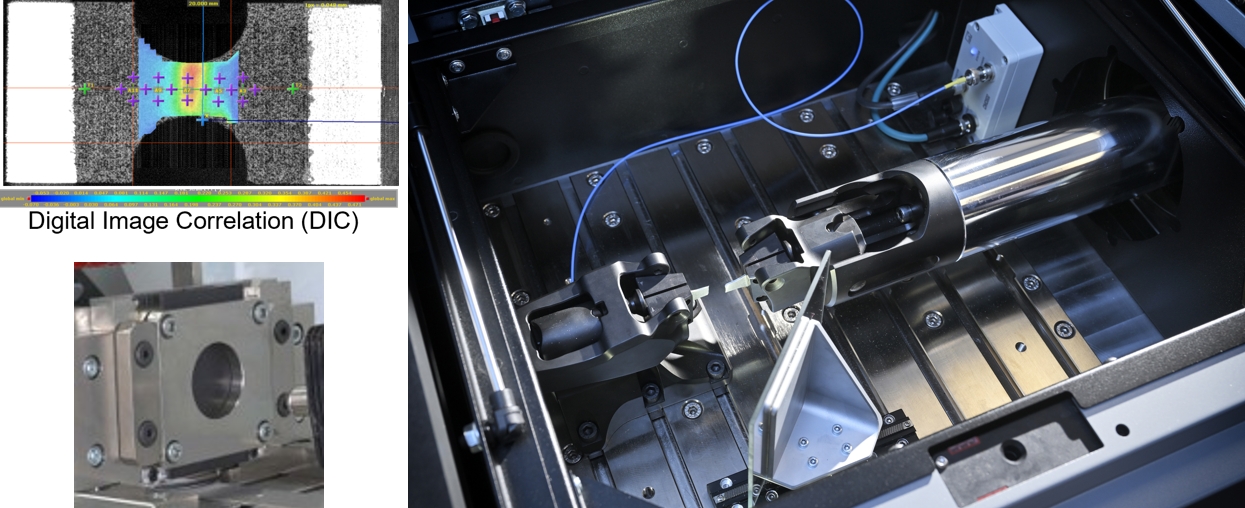

Advanced Testing Laboratory – Precision Meets Versatility

Our testing laboratory at LKR is equipped with the state-of-the-art LINOVIS® electro-dynamic testing system from 4a engineering, offering unparalleled flexibility for material and component characterization. Designed for static, dynamic, and cyclic testing, LINOVIS® enables us to replicate real-world loading conditions with exceptional accuracy.

Key Features of LINOVIS®

- Force capacity: up to 25 kN, even in static mode

- Three operating modes: static, dynamic, and cyclic

- Fast changeover: modular test setups within minutes

- Integrated DIC cameras: for full-field strain measurement

- Oil-free linear drive & rigid frame: ensuring consistent and precise testing conditions

Wide Range of Applications

Our LINOVIS ® system supports a broad spectrum of tests, including:

- High-fidelity material characterization

- Mechanical testing of battery cells and stacks

- Impact and crash-relevant component testing

- Complex multi-axial and combined loading scenarios

Seamless Integration with VALIMAT®

The VALIMAT ® software environment ensures an efficient workflow by combining test data and material models in a structured database. Automated communication between LINOVIS® and VALIMAT® enables:

- Rapid material model generation for LS-DYNA®, PAM-CRASH®, Abaqus® (*MAT_024, *MAT_187, MMATER, *PLASTIC, etc.)

- AutoFit process: fully automated parameter identification

- Validation: from coupon-level FEM tests to custom geometries and load cases

With LINOVIS® and VALIMAT®, we provide cutting-edge testing solutions for the development of advanced material models and the validation of forming and crash simulations.

![[Translate to English:] LKR Standort](/fileadmin/_processed_/1/f/csm_AIT_LKR_Standort_4fe61c1df0.jpg)