What’s semi-solid casting of Aluminum alloys and why is it so relevant?

Semi-solid casting is a metal processing technique in which an aluminum alloy is cast in a state that is neither fully liquid (as in traditional casting) nor fully solid, but instead in a mushy, slurry-like state containing both solid and liquid phases. Compared to conventional High Pressure Die Casting, this casting method is highly relevant especially for components in the transportation sector. The lower melt temperature, combined with the higher viscosity of the material and its thixotropic behavior, reduces turbulence during die filling, thereby improving casting integrity and minimizing porosity. In addition, it offers cost and energy efficiency: the reduced melt temperature decreases energy consumption in the holding furnace and lowers thermal fatigue on the die surfaces, ultimately extending the tool life.

What’s the key Idea behind the MELcon system?

The key idea behind the MELcon system is to develop a technologically innovative solution for producing semi-solid material using HPDC equipment. The system is designed to be flexible, capable of performing both conventional HPDC and semi-solid casting, and easily adaptable to existing HPDC setups.

How does It work?

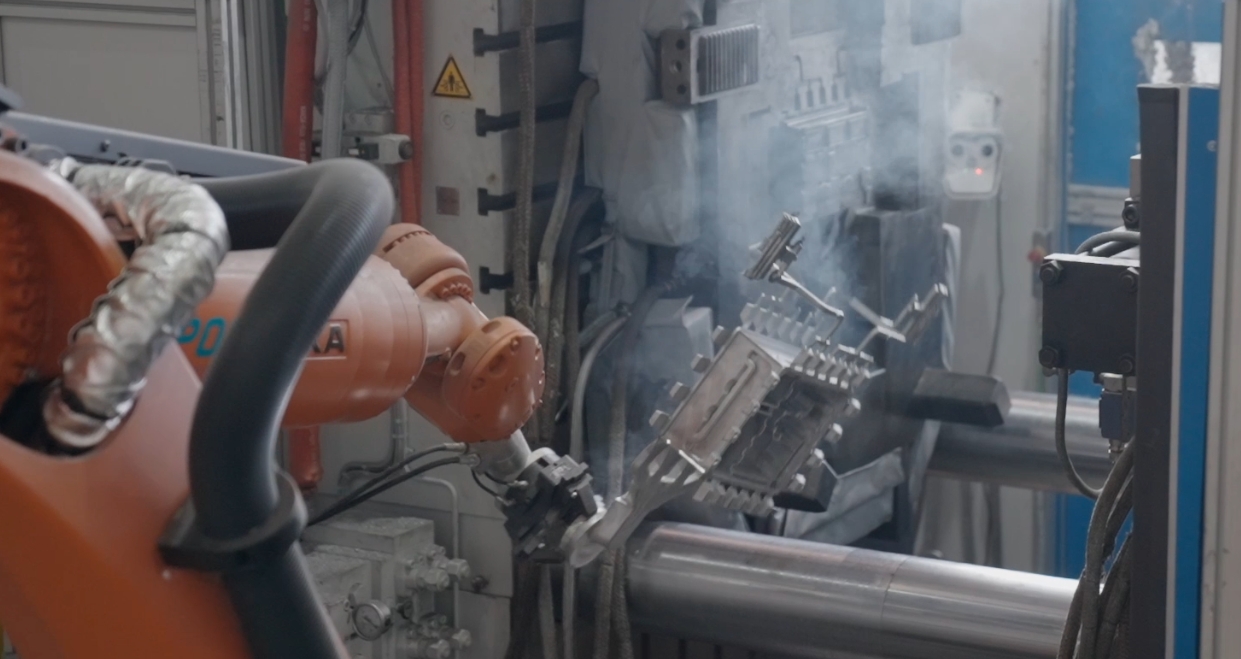

The process begins with a pipette system that extracts molten material from the holding furnace. To prevent oxidation, the system is flushed with inert gas. The material is then transferred to the HPDC machine, positioned over the pouring hole. At this stage, an induction coil is activated. This coil generates an electromagnetic field that stirs and conditions the material. As the material cools, the electromagnetic force fragments and rounds the primary aluminum dendrites. This transformation continues until the desired temperature is reached, at which point the semi-solid material is poured into the casting chamber.

What’s the target solid fraction during the process?

We adjust the solid content to optimize it for the process and the component. This significantly reduces turbulence and surface irregularities when filling the mold, which greatly improves component quality. Importantly, this solid fraction does not require a drastic change in the conventional HPDC approach to casting parameters (though some adjustments are strongly recommended).

What Are the main advantages of Semi-Solid Casting with the MELcon system?

- Reduction of porosity, resulting in improved mechanical properties and overall part quality.

- Minimization of oxide entrapment to enhance the material integrity.

- Extended tool life due to the reduction of thermal fatigue stresses.

Validation in the laboratory and in the field

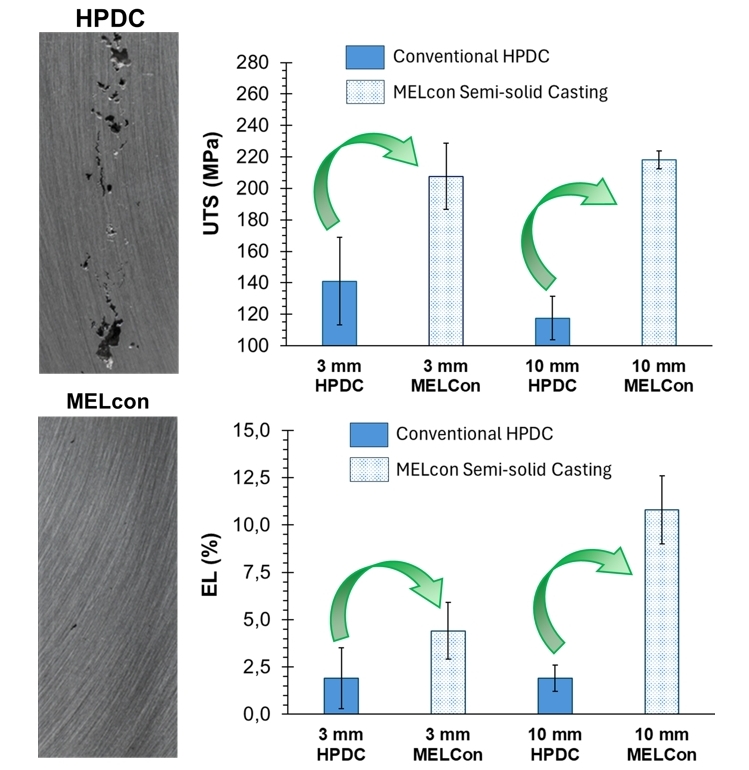

Laboratory trials with the MELcon system demonstrated a clear reduction in air entrapment and porosity compared to conventional HPDC, regardless of part thickness (3 mm or 10 mm). This decrease in internal defects positively impacts mechanical performance, resulting in higher elongation to fracture (EL) and ultimate tensile strength (UTS).

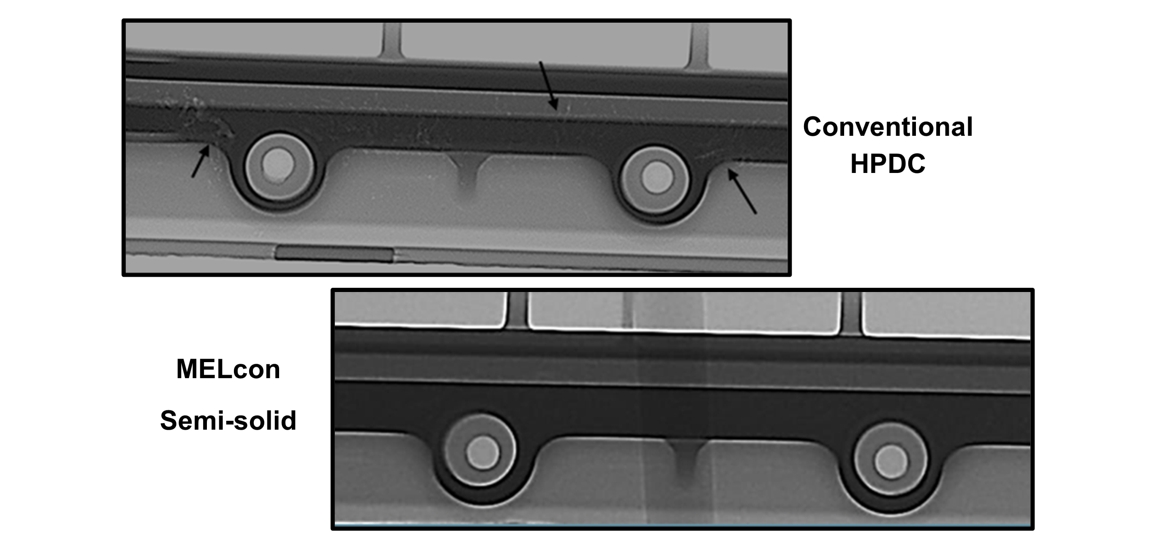

The effectiveness of the MELcon system has also been validated in an industrial setting by a project partner. In this case, a flat component previously affected by porosity issues was cast using both conventional HPDC and semi-solid casting with the MELcon system. The semi-solid approach resulted in a noticeable improvement in part quality.

Effect on the microstructure

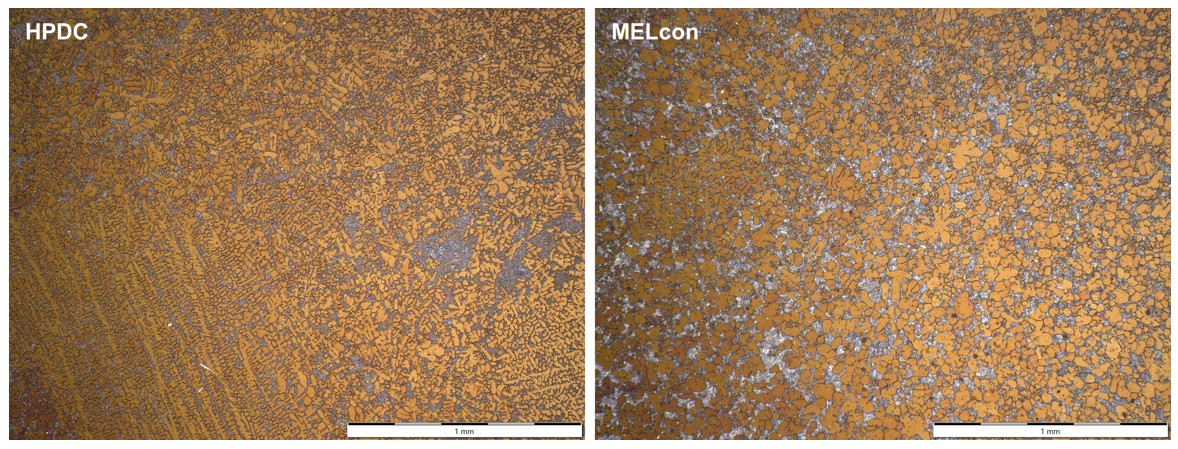

Compared to conventional HPDC, the MELcon system promotes the fragmentation of dendrites during the conditioning phase. As a result, the microstructure formed exhibits a refined, rosette-like morphology of the primary α-Al phase, as shown in the Figure below.