Moving away from traditional alloying paradigms

The recent past has produced a variety of alloying concepts that differ radically from the traditional approach of a basic element with small additions of other alloying elements. Significantly within the so-called High Entropy Alloys (HEA), which despite the absence of a decited main element show simple, single-phase microstructures, a series of alloys with previously unattained absolute and specific strengths have been developed.

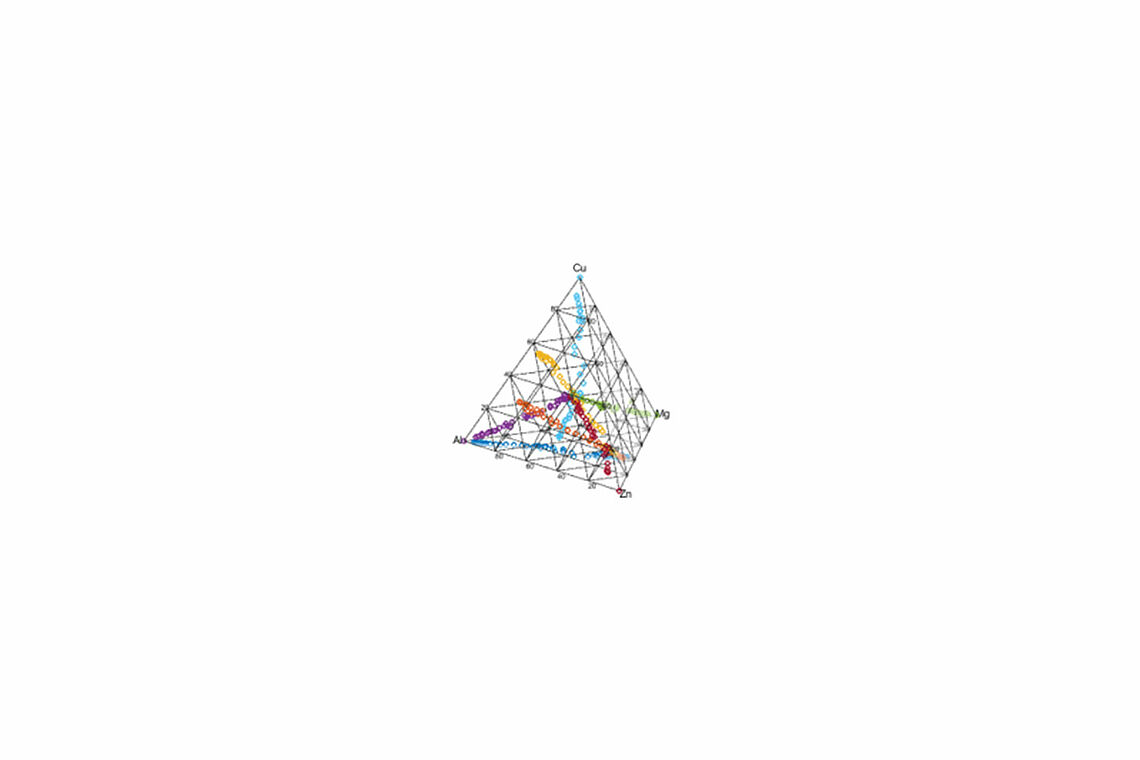

Common to all concepts is the imperative to advance into the central areas of complex phase diagrams where classical models fail.

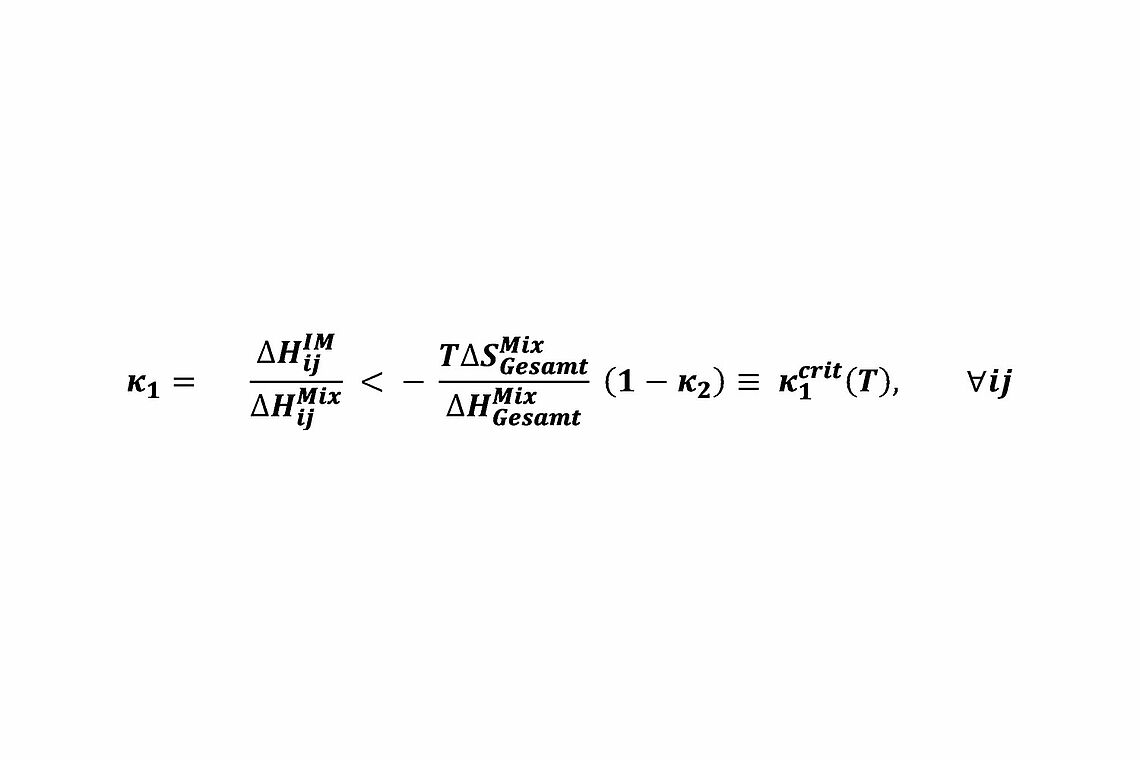

The transfer of these concepts to the light metal regime requires a fundamental rethinking of the elementary phase formation mechanisms. The LKR is doing basic research in the field of light metal HEAs to answer the question: Do light metal HEAs exist at all? Together with European research partners, screening methods are being developed that combine the precision of atomistic simulation with the speed of statistical methods and are accessible to experimental methods.

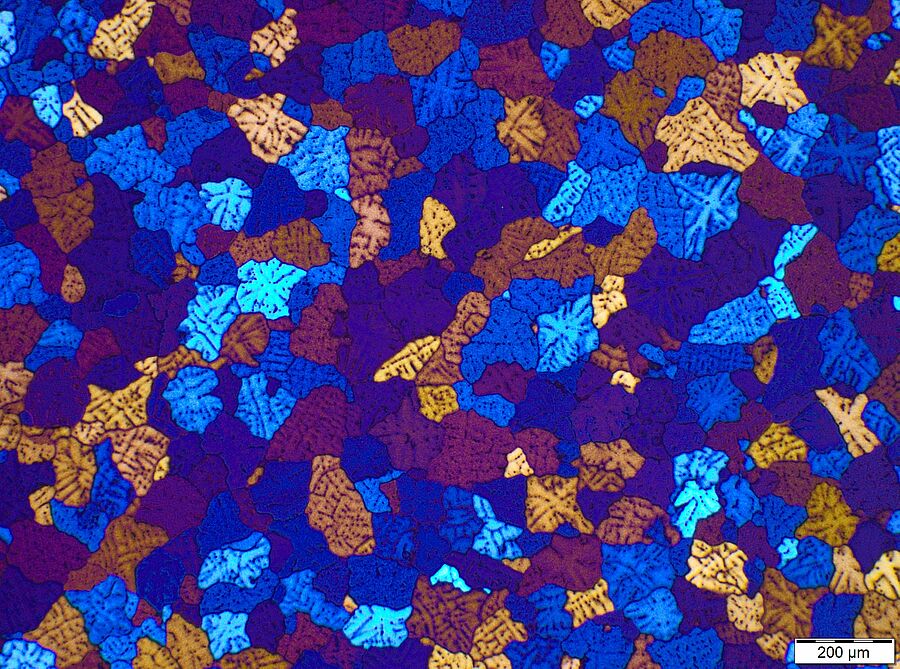

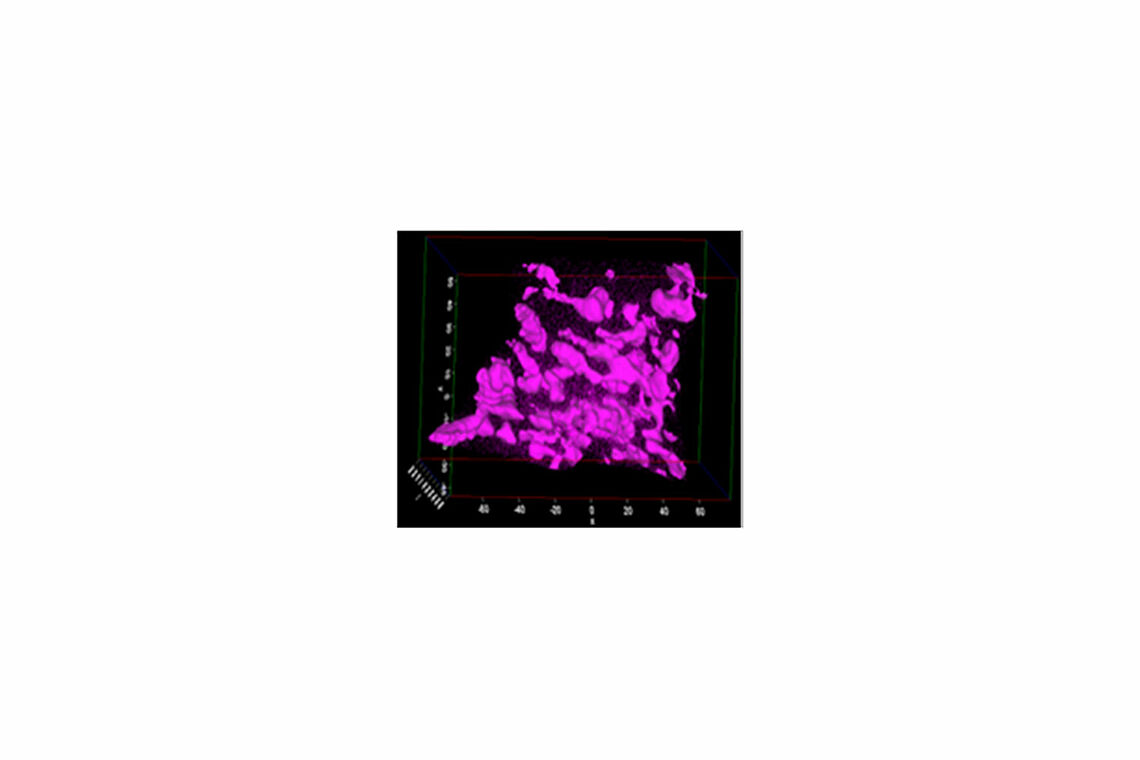

One focus of the LKR's research activities concerns the development of nanostructured eutectic alloys. In principle, eutectic compositions form fine structures with advantageous properties already in the as-cast state, i.e. without the use of further process steps. Extrapolation into higher stoichiometric dimensions using modern methods such as CALPHAD allows these structures to be rescaled into the nanometer range and brings a leap in the achievable properties. The concept developed at the LKR is independent of a basic element and can be applied to magnesium, aluminium and titanium based systems.

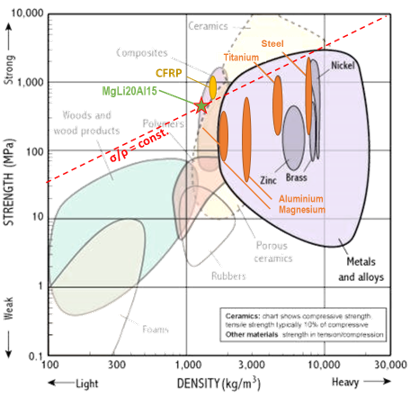

On the basis of these concepts, a magnesium-lithium ultra-light alloy was developed and patented at the LKR, which at a density of 1.25 g/cm³ achieves strengths of up to 450 MPa, and is thus on a par with carbon fiber composites in terms of its specific strength.

While many high-performance alloys can only be produced on a laboratory scale by means of extreme special manufacturing processes, all developments at the LKR are subject to the maxim of final reproducibility with industry-relevant primary forming processes. The complete in-house portfolio of semi-industrial casting plants ensures permanent networking between experimental implementation and alloy design.

![[Translate to English:] LKR Standort](/fileadmin/_processed_/1/f/csm_AIT_LKR_Standort_4fe61c1df0.jpg)