Whether in ice cream, chilled fruit juice, or a refreshing soft drink – especially in summer, sugar is an indispensable part of everyday life for many people. In Austria, sugar is predominantly produced from locally grown sugar beets, which are harvested each year, stored temporarily, and processed into sugar.

However, during storage, valuable sugar can be lost – particularly due to damage sustained during harvesting, as well as from rot or mold formation. Quality control of the beets has so far been carried out mostly manually and subjectively – a process that is difficult to scale. At the same time, there has been a lack of both suitable image datasets and specialized AI methods for objective and automated assessment.

Such assessment, however, is essential as a solid basis for estimating the expected sugar yield and for optimizing storage conditions.

SemanticSugarBeets: AI for Objective Evaluation of Sugar Beet Batches

With “SemanticSugarBeets”, the AIT Austrian Institute of Technology (AIT) presents a new method for the automated, visual inspection of sugar beets. The goal is to improve quality control along the entire value chain, minimize sugar losses, and make storage and processing significantly more efficient.

“With our expertise in AI-based object detection, the development of publicly available datasets, and easily deployable technologies, we make an important contribution to the digitalization of agriculture,” says Gerardus Croonen, who leads the project at the AIT. Croonen is an expert in sensing and optical inspection at the AIT Center for Vision, Automation & Control.

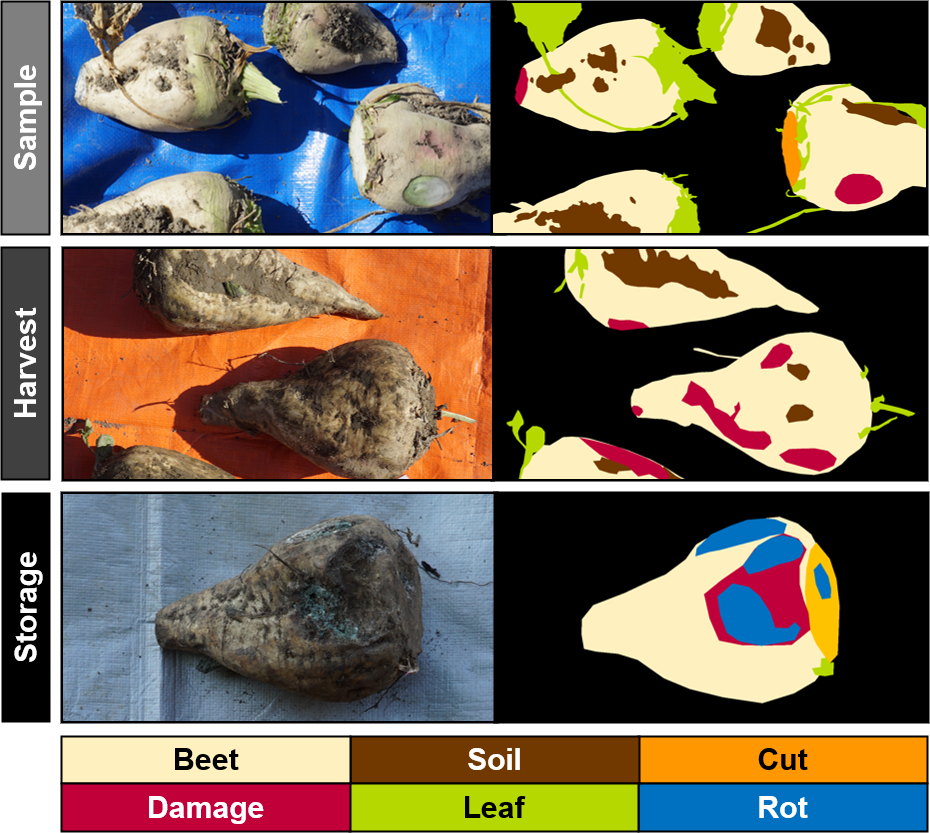

At the heart of the project is a comprehensive, publicly accessible image dataset containing around 3,000 sugar beets and over 950 high-resolution images. These were taken under varying environmental parameters – such as different lighting and weather conditions – and across three processing stages: manual harvesting, mechanical harvesting, and storage after 90 days. All images are annotated with multiple relevant quality characteristics.

The two-stage analysis developed by the researchers combines efficient detection of individual sugar beets with precise automatic segmentation of areas containing, for example, leaf residues, cut surfaces, or rot. The method achieves an impressive detection accuracy of 98.8 % for beet identification and 64 % for the semantic classification of individual quality parameters.

In addition, the system enables a realistic estimation of the mass of individual sugar beets – based on their surface area and a reference object captured in the image. This makes automated, objective, and scalable evaluation of entire beet batches possible – with direct benefits for both agricultural producers and industrial processors.

Open to New Crops – Invitation to the Expert Community

In the future, the project will be expanded to cover additional environmental conditions and other crops such as carrots or potatoes.

Researchers and companies are invited to use, test, and further develop the publicly available models and datasets.

Github: github.com/semanticsugarbeets/semanticsugarbeets

Scientific Paper: https://arxiv.org/pdf/2504.16684

Contact

Gerardus Croonen

Assistive & Autonomous Systems

Center for Vision, Automation & Control

gerardus.croonen@ait.ac.at