Automated goods handling in logistics and municipal services

Automated truck-mounted forklift.

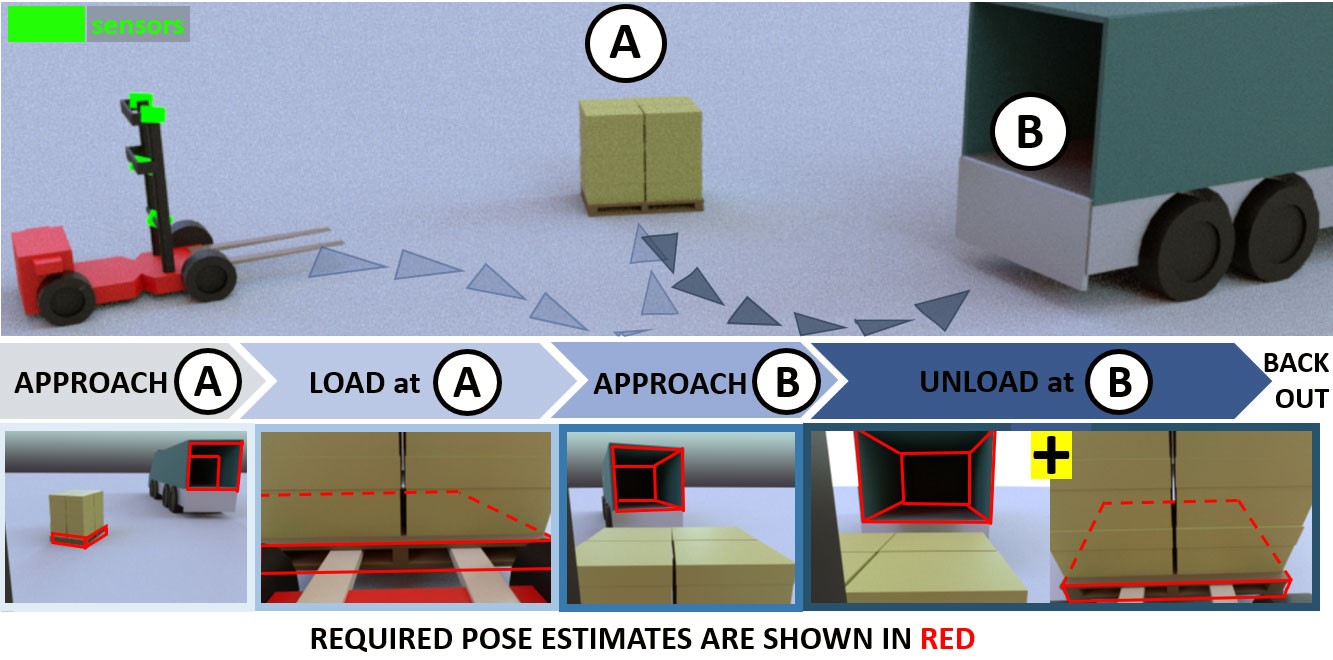

In many commercial production and transport processes, loading and unloading goods, especially outdoors, is an essential part of the work process. This is often done manually and requires fast and accurate positioning. Standardised transport items, such as pallets, are used for loading onto a loading area. In addition, there are a large number of similar tasks that require a different form of handling, such as emptying recycling bins.

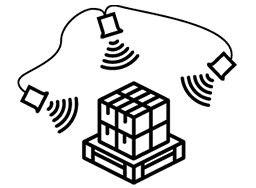

In the HOPPER project, we are developing assistance systems for large machines. The aim is to automate difficult subtasks to ensure high quality and safety in the work process. Our solutions are based on sensor-based methods for automated positioning, path planning and object recognition. By using these technologies, automated systems such as forklifts gain a comprehensive understanding of the entire scene. This makes it possible for the first time to automate the handling of goods and objects outdoors, for example during loading and unloading operations. Our solutions can also be used for similar tasks, such as emptying waste containers.

The HOPPER project covers all steps from concept to sensor technology and execution on automated platforms. The results of the project will serve as a basis for further research and development for the automation of various tasks for the handling of known objects at different scales.

- near: pallet loading

- remote: automated crane

and different application areas

- agriculture

- construction

- logistics

Challenges

Automating these complex actions, which may involve several large devices that need to be coordinated, is a particular challenge. The implementation requires centimetre-precise operation and a clear abstraction of the scene, including a clear definition of the object relationships within it. The technological response to the task-specific challenges is based on a set of complementary representations of the environment and optimal path and motion planning with non-linear constraints.

SENSING, POSITIONING, PATH PLANNING, OBJECT RECOGNITION AND COGNITIVE DECISION-MAKING

Automated loading and unloading: Continuous position estimation assists the vehicle during loading. Sensors continuously provide position-specific information that is used as a target for path planning. © AIT, C.Beleznai

Results

With the completion of the project, all of HOPPER's set goals were achieved and the forklift was automated.

- localisation of specific objects despite occlusion of up to 80%.

- development of object recognition methods based on synthetic and real data

- flexible planning methods and precise control for work processes

- simulation-based optimisation of complex systems

The technologies are key elements within the operational process. This involves sensing the environment by means of sensors, recognising and interpreting the scene, right up to controlling and reacting, i.e. cognitively deciding how the object should be handled:

These key technology components for automated handling of objects in various loading and manipulation processes in logistics have been developed, integrated and successfully demonstrated. They can also be used in municipal services and similar applications in the future.

For more information please also check

the press release (only in German)

FFG

Funding

The research project HOPPER (Handling of man-made Objects using automated Positioning, Planning and Enhanced Reasoning methods) has received funding from the „IKT der Zukunft“ programme of the Republic of Austria, Ministry for Climate Action (BMK).