PUlsed Laser depoSition tEchnology for soLid State battery manufacturIng supported by digitalizatiON

Europe’s objective to have 30 million electric vehicles on the roads by 2030 can only be achieved by large scale European production of highly effective, high-performing batteries. Development of solid-state battery technologies could markedly improve the energy density and safety of lithium metal batteries.

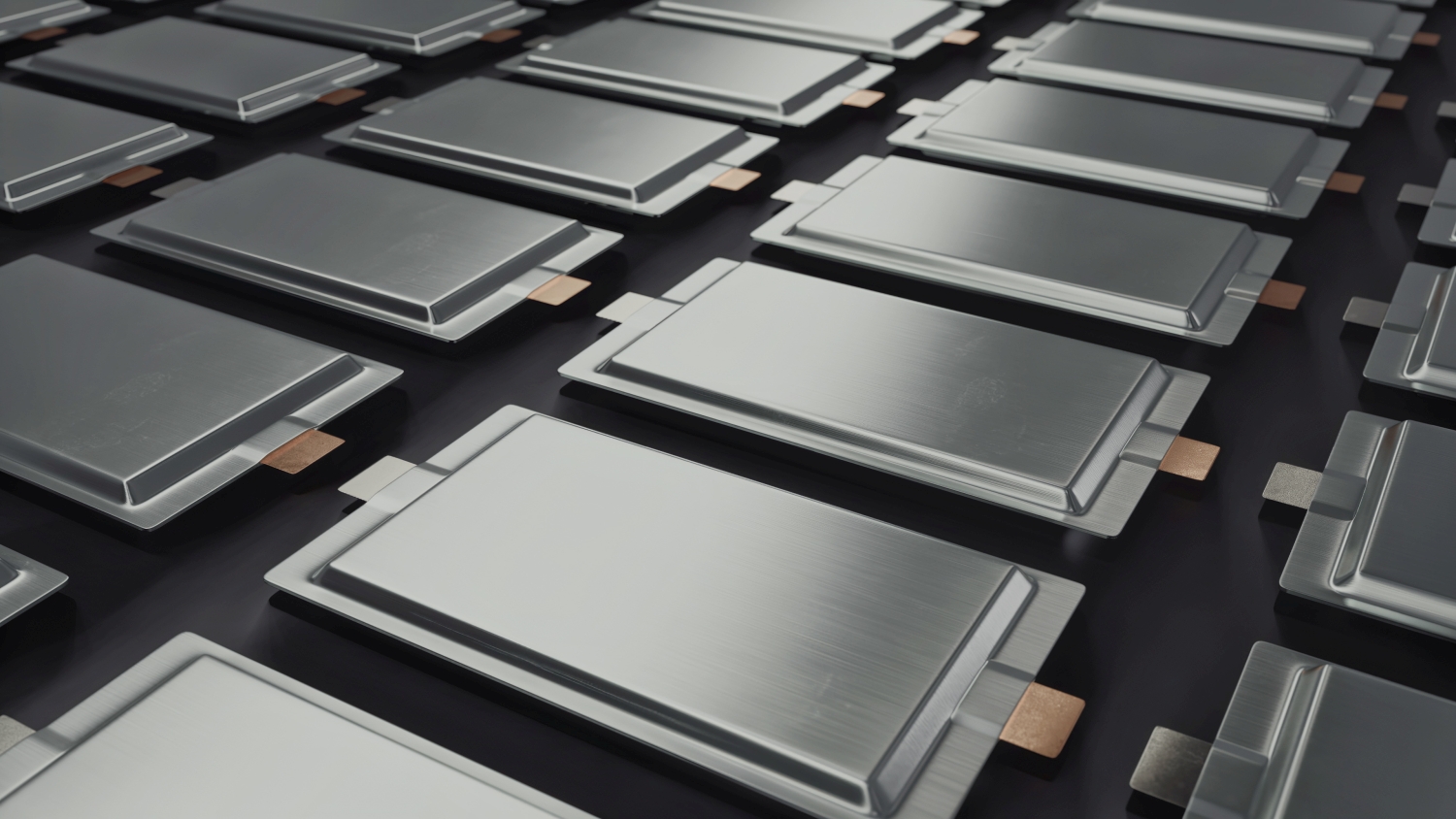

Mass manufacturing of solid-state batteries is still in the research and development phase. In order to make solid-state batteries meet the needs of the EV market in terms of cost and performance, a standard process needs to be developed.

PULSELiON (PUlsed Laser depoSition tEchnology for soLid State battery manufacturIng supported by digitalizatiON) will bring Pulsed Laser Deposition (PLD) based solid-state battery manufacturing technology from the laboratory scale to a practical demonstration of industrial applicability, which has not been done before. This project will enable EU producers to upscale, process, and manufacture solid-state batteries by utilising commercially available materials together with advanced technology materials.

The PULSELiON project aims to develop the manufacturing process of Gen 4b solid-state batteries based on a lithium-metal anode, sulfide solid electrolytes, and a nickel-rich NMC cathode. A novel pulsed laser deposition technique developed in its predecessor PULSEDEON will be adapted and modified into a single-step vacuum process for safe and efficient manufacturing of anode components composed of lithium metal, protective layers, and sulfide-based solid electrolytes. The cathode layer will be made with conventional wet processing techniques. Initially, the anode and cathode layers will be developed on a small scale for making coin cells and monolayer cells to facilitate optimization of the materials and processes. Solid-state battery cells will be developed with optimized process routes and will be upscaled to a pilot line proof-of-concept (TRL 6) by manufacturing large-scale solid-state batteries (10 Ah). Digitalisation will be incorporated into the process modelling task with the inputs obtained from process upscaling and cell testing, which will enable efficient process optimization.

The ambition of the PULSELION project relates to a solid-state battery with a sulfide-based electrolyte, high energy density cathode materials, and advanced lithium metal anode. The AIT experts will use their expertise in the interfacial modification of battery components and the production of cells on a small and large scale to help develop wet chemical cathode and electrolyte formulations. Furthermore, they will perform physicochemical and electrochemical characterisation of battery components and full cells to provide further improvements in terms of safety and ageing.

AIT battery researcher Artur Tron: "The PULSELiON project aims to advance the manufacturing process for the next generation of solid-state batteries and to develop a battery with high performance and safety. By adapting pulsed laser deposition technology, we enable efficient and safe manufacturing of battery components - thus we want to make a significant contribution to strengthening European battery production."

Project video

This project has received funding from European Union’s Horizon EUROPE Research and Innovation Programme under Grant Agreement N° 1101069686 (PULSELiON).