Enabling MULTI-FUNctional performance through multi-material additive manufacturing

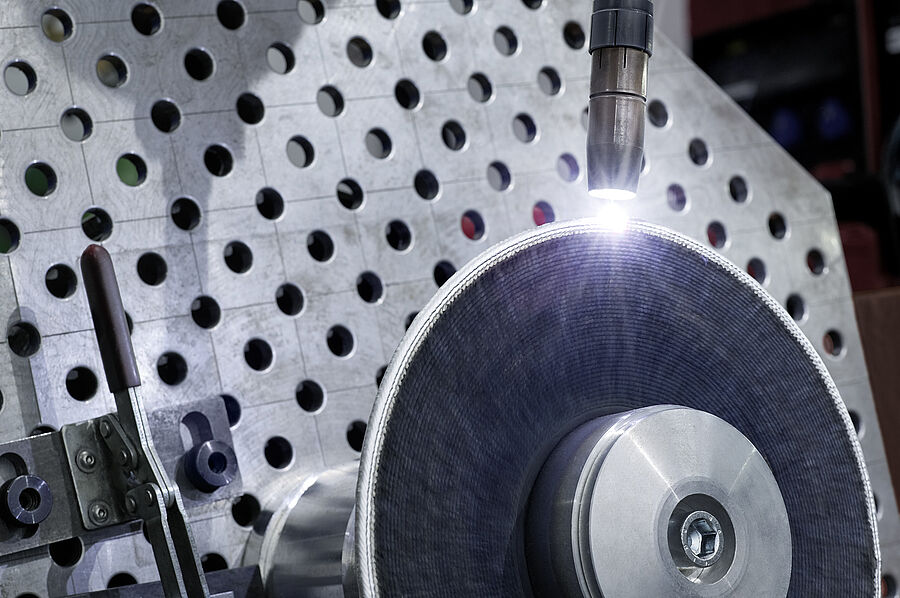

MULTI-FUN sets a clear focus on market-creating innovation, developing advanced materials and equipment for Additive Manufacturing of multi-material parts. These new material combinations will provide a significant performance & efficiency gain in MAM products by fully integrated multi-functionalities based on novel active materials and enable MULTI-MATERIAL design in geometrically complex 3D metal parts without size limitations by innovative, cost-effective AM technologies. The novel integrated functionalities include embedded electrical conductivity, fibre-optical sensing features or innovative heat management concepts, incl. applying nanotechnologies in at least 3 variants.

Leading experts in AM process & equipment manufacturing (from SMEs, IND, RTOs and UNIV) will fully cover the physical integration of these advanced materials into metallic substrates. Significant improvements in efficiency, quality & reliability of products will result in KPI numbers beyond the request (>40%), alongside reduced environmental impact as well as lower costs also much better than the given number of >35%.

The evaluation assessment (reg. general performance & quality of novel functionalities) and LCA will be performed on 7 industrial demonstrators, addressing structural parts, moulds and test equipment for aerospace, automotive and general industrial usage.

By wide usage of cost-effective wire & arc-based AM systems, complemented by efficient powder processing methods (esp. thin multi-material features), market uptake will be benefited, esp. for SMEs. MULTI-FUN includes 9 EU SMEs as key players in advanced materials research for AM, providing a great opportunity to accelerate market uptake. Stakeholder involvement (e.g. reg. Certification & Standardization) will foster business models & marketing of strong USPs of MULTI-FUN.

Facts

- MULTI-FUN - Enabling MULTI-FUNctional performance through multi-material additive manufacturing

- Programme: H2020-EU.2.1.3. - INDUSTRIAL LEADERSHIP / H2020-EU.2.1.2. - INDUSTRIAL LEADERSHIP

- Funding agency: EU

- Duration of project: 03/2020 – 02/2023

- Projectcoordination: AIT Austrian Institute of Technology / LKR Leichtmetallkompetenzzentrum Ranshofen

Project partners

- VOESTALPINE METAL FORMING GMBH

- DEUTSCHES ZENTRUM FUER LUFT - UND RAUMFAHRT EV

- FUNDACION BCMATERIALS - BASQUE CENTRE FOR MATERIALS, APPLICATIONS AND NANOSTRUCTURES

- INOCON TECHNOLOGIE GMBH

- FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG E.V.

- LORTEK S COOP

- INPHOTECH SP ZOO

- INSTITUTO DE SOLDADURA E QUALIDADE

- MIGAL.CO GMBH

- EUROPEAN FEDERATION FOR WELDING JOINING AND CUTTING

- RHP TECHNOLOGY GMBH

- CRANFIELD UNIVERSITY

- WAAM3D LIMITED

- AEROTECNIC METALLIC SL

- EDAG ENGINEERING GMBH

- PEAK TECHNOLOGY GMBH

- ALPEX TECHNOLOGIES GMBH

- RUAG SPACE GMBH

- ALUWAG AG

- AVL LIST GMBH