Eliminating VOC from battery manufacturing through dry or wet processing

The European project NoVOC has a focus on environmentally sustainable processing techniques applied to large scale electrode and cell component manufacturing for Li ion batteries. The activities of NoVOC are tailored to the challenges addressed by as following:

- Lower carbon footprint cell manufacturing in Europe

- New sustainable electrode and cell manufacturing techniques with low energy consumption, and no Volatile Organic Compounds (VOCs) emissions

- Elimination of organic solvents in the production of electrode coatings, which reduces the costs associated with the solvent recovery system

- Dry manufacturing techniques with next generation materials

- Industrializing closed loops and process design to return low-value chemicals from manufacturing processes to high-value products

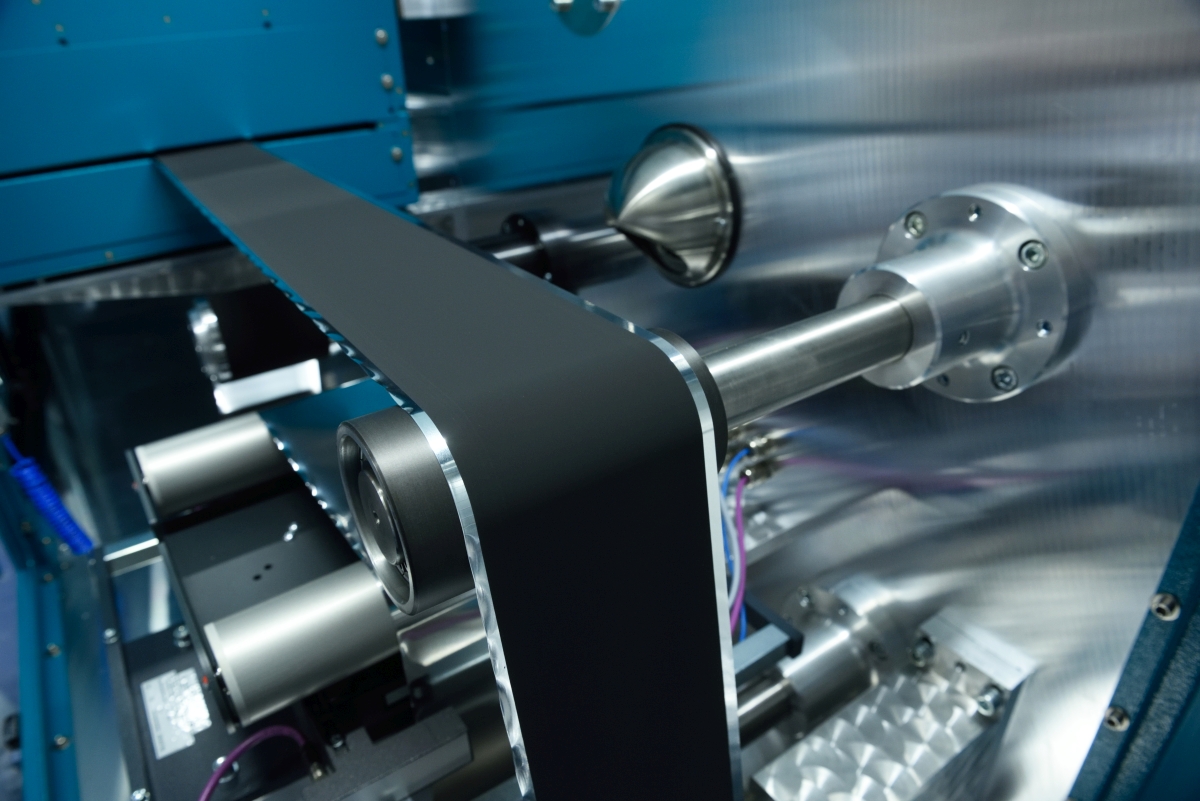

Within the framework of NoVOC, aqueous and dry cell production technologies for traction batteries produced in Europe are to be developed and demonstrated. The innovations proposed in NoVOC centre on improvements of the cell manufacturing process by integrating two novel electrode manufacturing processes into the currently available cell assembly process. They demonstrate the manufacturability of automotive cells in two formats (pouch and cylindrical) without toxic organic solvents at a fraction of today's cost.

AIT is responsible for upscaling the electrodes to pilot scale using an environmentally friendly wet process. In addition, the first representative pouch cells of NoVOC are assembled at pilot scale in our research pilot line.

Battery researcher Buket Boz from the AIT Center for Transport Technologies: "Within the framework of the NoVOC project, we make a decisive contribution to the resource-efficient, sustainable and climate-friendly production of battery cells - an ambitious goal, which, however, appears to be entirely feasible together with our partners in this top-class European research consortium".

This project has received funding from European Union’s Horizon EUROPE Research and Innovation Programme under Grant Agreement N° 101069612 (NoVOC).