Predicting Heat and Distortion

Wire Arc Additive Manufacturing (WAAM) offers a powerful alternative to powder-bed processes for producing large-scale metal components. With its high deposition rate, WAAM enables significantly faster build times, making it ideal for structural parts in aerospace, automotive, and energy sectors.

However, the process involves intense thermal cycles, which strongly influence material properties, residual stresses, and distortion. To ensure component quality and dimensional accuracy, predicting these effects is essential.

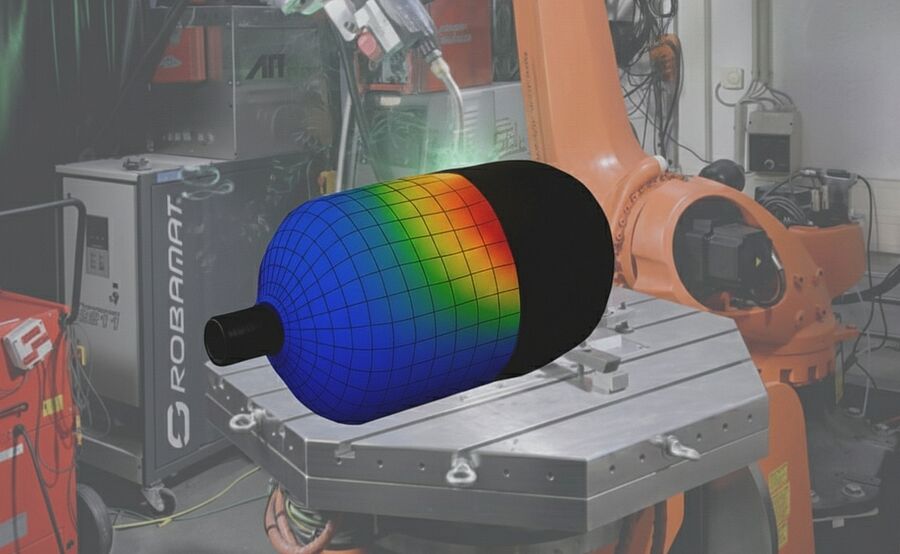

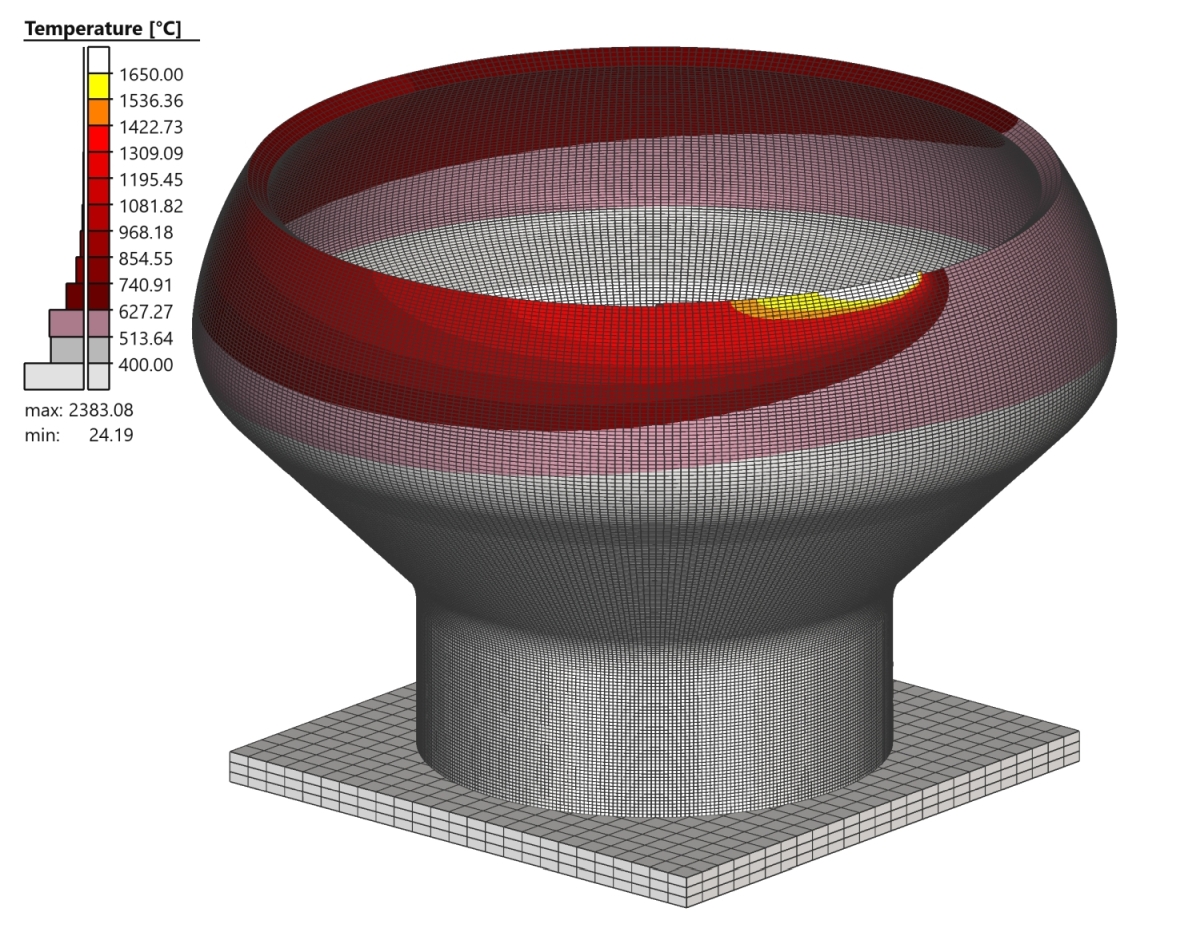

At LKR, we use commercial simulation software such as Simufact welding as well as self-developed finite element-based simulation models based on Finite-Elemente Solver LS-DYNA®, that replicate the WAAM process, enabling:

Temperature field prediction during layer-by-layer deposition

Residual stress and distortion analysis

Process optimization for improved stability and reduced defects

By combining simulation insights with our in-house WAAM manufacturing capabilities, we close the loop between virtual process design and real-world validation, accelerating the development of robust additive manufacturing solutions.

![[Translate to English:] LKR Standort](/fileadmin/_processed_/1/f/csm_AIT_LKR_Standort_4fe61c1df0.jpg)