Predicting Phase Transformations

Thermodynamic and kinetic simulations enable solutions to be found more quickly and cost-effectively than traditional trial-and-error methods. They also offer valuable insights into the processes occurring in materials under different conditions, helping to understand the formation of specific microstructures and their impact on the material’s evolution.

Simulation services

Casting: (Phase stabilities): The evaluation of segregation and primary precipitation during casting can be performed using the available thermodynamic description, based on the Scheil-Gulliver or equilibrium calculation.

Heat treatment: The effects of heat treatment operations on the alloy structure can be studied using thermodynamic and diffusion databases. Solutions for various heat treatments, such as homogenization, solution treatments, aging, and annealing, are offered.

Precipitation evolution: The sizes, numbers, and compositions of the precipitates can be tracked throughout the entire thermomechanical process chain.

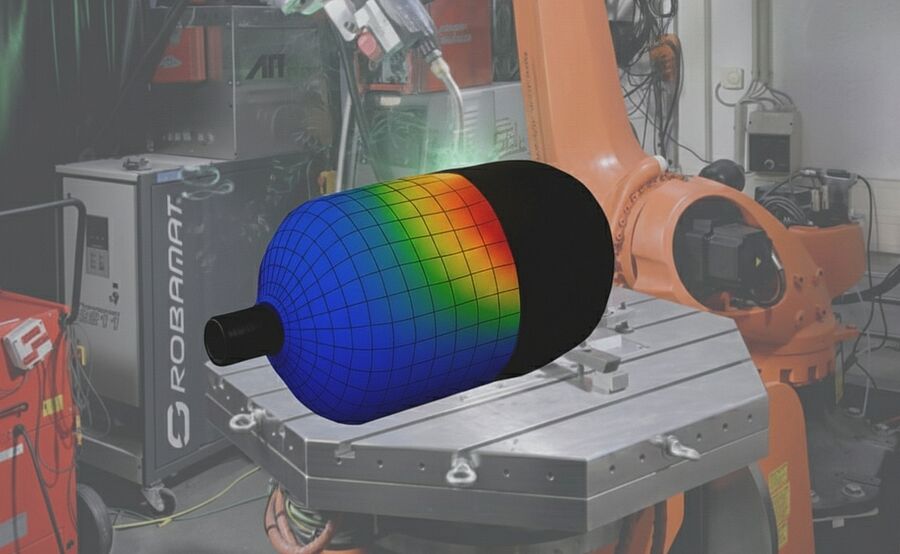

Microstructure modeling (material deformation): Using available modeling techniques, the microstructure parameters (grain size, precipitates, …) and mechanical properties (yield limit, flowstress modelling) of different materials can be calculated during and/or after various thermomechanical processes, such as rolling, extrusion, and forging assuming that the material is homogeneous.

One of the main goals for the simulation is the influence of process modifications on the final material properties – based on the simulated microstructure evolution.

![[Translate to English:] LKR Standort](/fileadmin/_processed_/1/f/csm_AIT_LKR_Standort_4fe61c1df0.jpg)