Understanding Microstructure Evolution

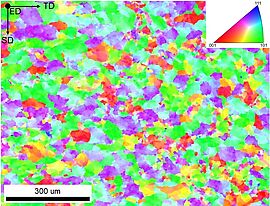

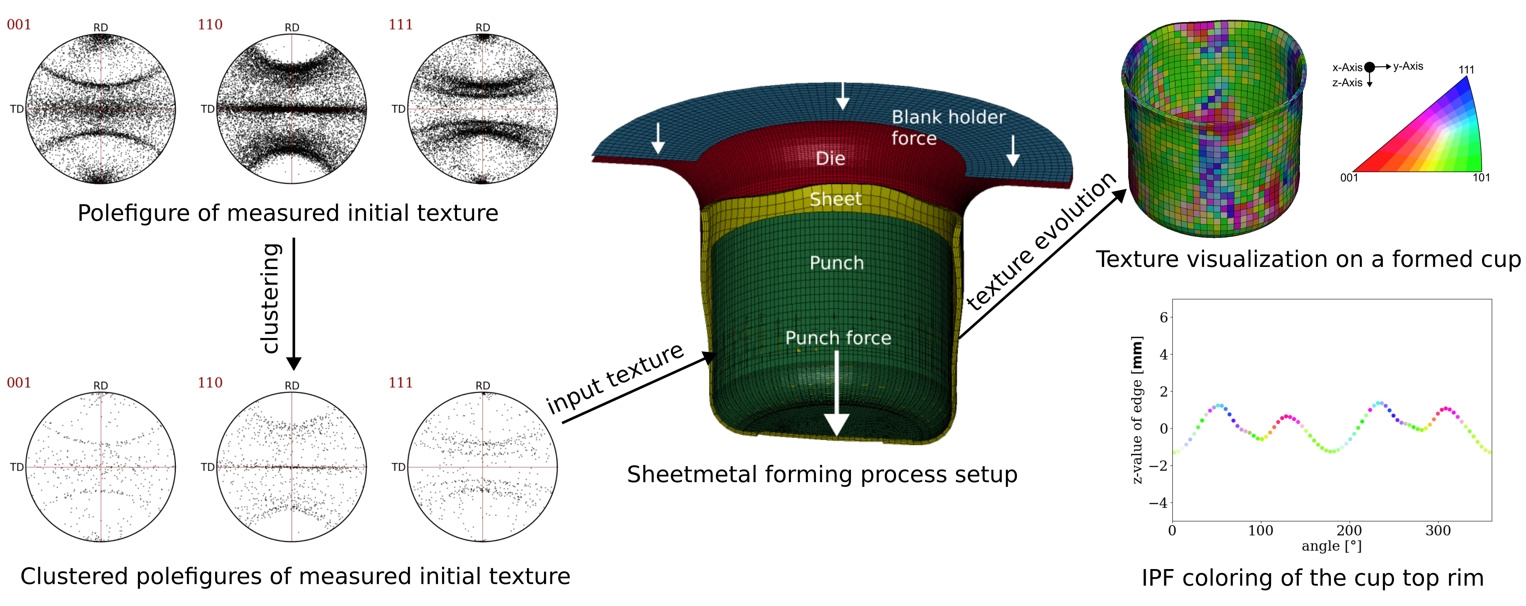

The mechanical properties of light metals—such as strength, formability, and fatigue resistance—are strongly influenced by their microstructure. Both plastic deformation processes and heat treatments lead to significant changes in the material’s internal structure. Predicting and controlling these changes is essential for designing robust processes and high-performance components.

Mechanisms and Modeling Approaches

Microstructure evolution is a complex interaction of mechanisms that depend on process conditions. We cover for:

- Forming processes: grain deformation, texture evolution, and dynamic recrystallization

- Heat treatments: grain growth, static recrystallization, and phase transformations

To capture these phenomena, we apply a range of numerical methods:

- Crystal plasticity: VPSC model for grain deformation and texture development

- Recrystallization: LKR Flow and ReX models based on Kocks-Mecking-Estrin and JMAK approaches

- Phase transformations: CALPHAD-based tools (MatCalc, Thermo-Calc)

Focus on Processes

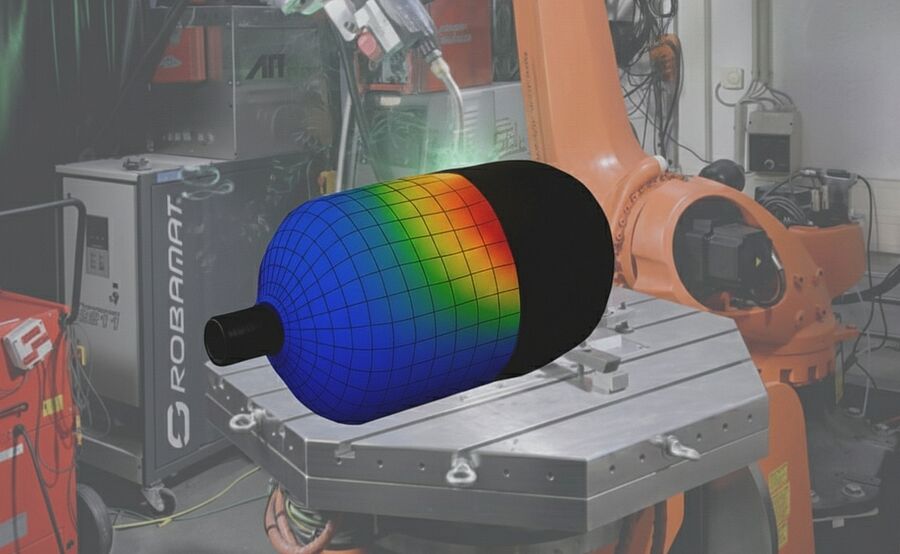

Our models cover the entire process chain—from solidification (casting, additive manufacturing) through bulk forming (rolling, extrusion, forging) to heat treatments (homogenization, solution treatment, aging).

Validation and Integration

Simulation results are validated through comprehensive experimental characterization and semi-industrial trials, ensuring reliable integration into process simulations.

Future-Oriented Approaches

In addition to physics-based models, we develop hybrid approaches that incorporate data-driven methods such as machine learning to reduce uncertainties and better capture complex interactions.

![[Translate to English:] LKR Standort](/fileadmin/_processed_/1/f/csm_AIT_LKR_Standort_4fe61c1df0.jpg)