View into the unknown

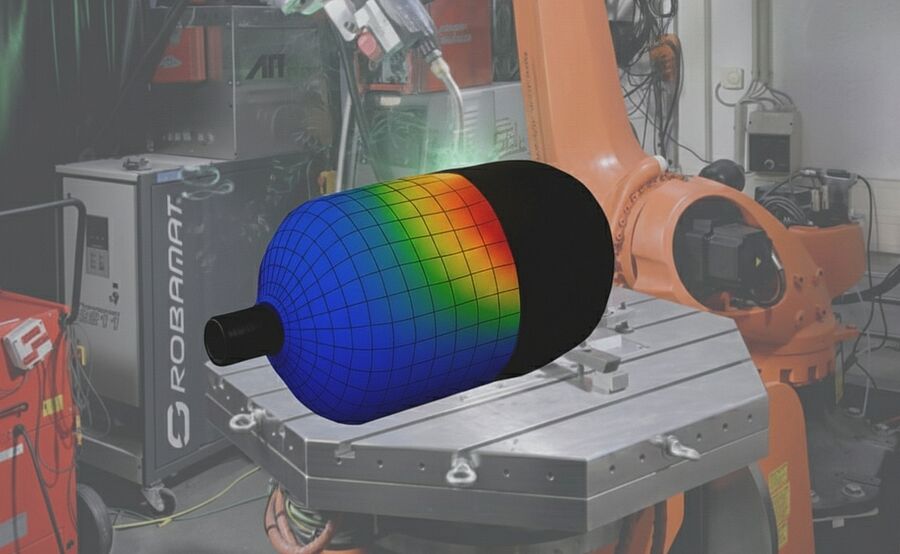

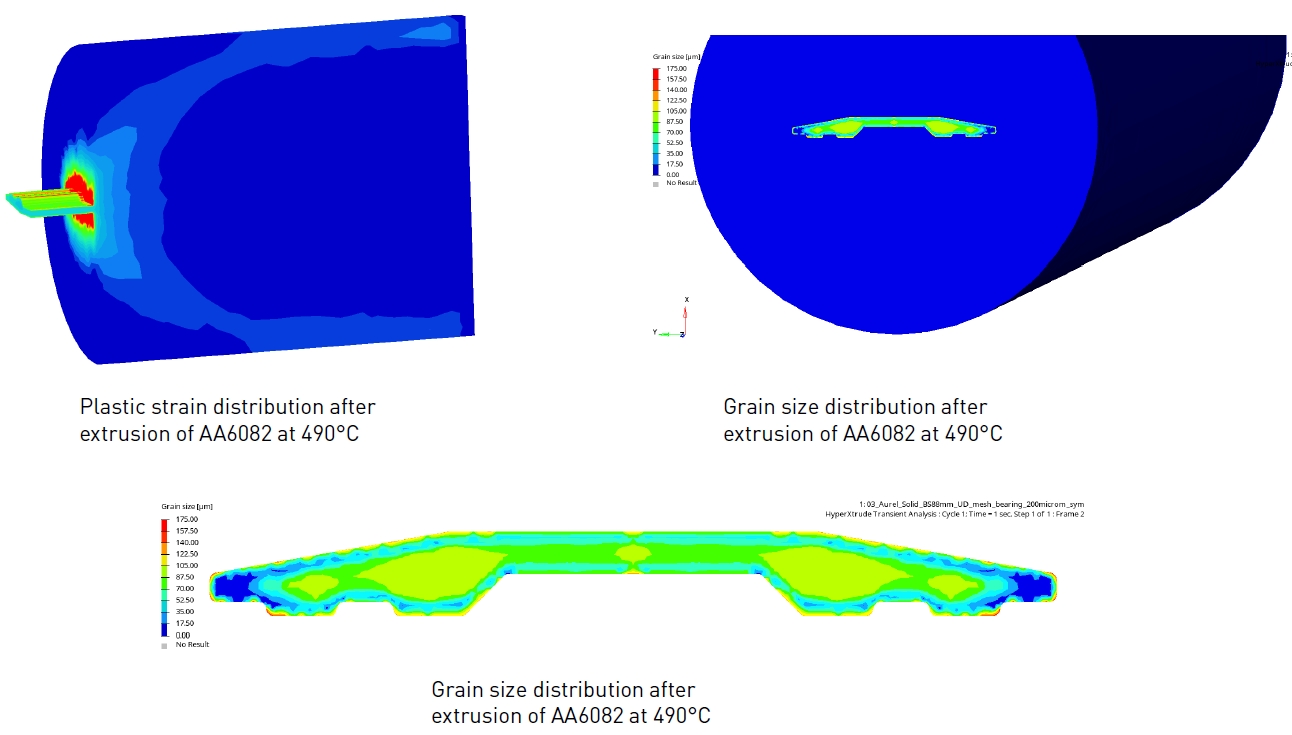

Extrusion is a key process for producing profiles with complex geometries from aluminum and magnesium alloys. Simulating this process provides deeper insights into material flow and thermo-mechanical behavior—an essential step toward optimizing die design, process parameters, and overall system performance.

Our Simulation Methods

At LKR, we combine:

VOF-based commercial tools such as HyperXtrude for industry-oriented applications

In-house developed microstructure models based on mean dislocation density theory and JMAK (Johnson-Mehl-Avrami-Kolmogorov) for simulating grain morphology and static/dynamic recrystallization incl. particle stimulated nucleation.

In-house developed methodologies for mapping streamline-based results (based on standalone codes) to parts of a 3D process simulation model.

By integrating industrially proven tools with advanced research methods, we create the foundation for efficient, reliable, and innovative extrusion processes.

![[Translate to English:] LKR Standort](/fileadmin/_processed_/1/f/csm_AIT_LKR_Standort_4fe61c1df0.jpg)