Precision for Complex Geometries

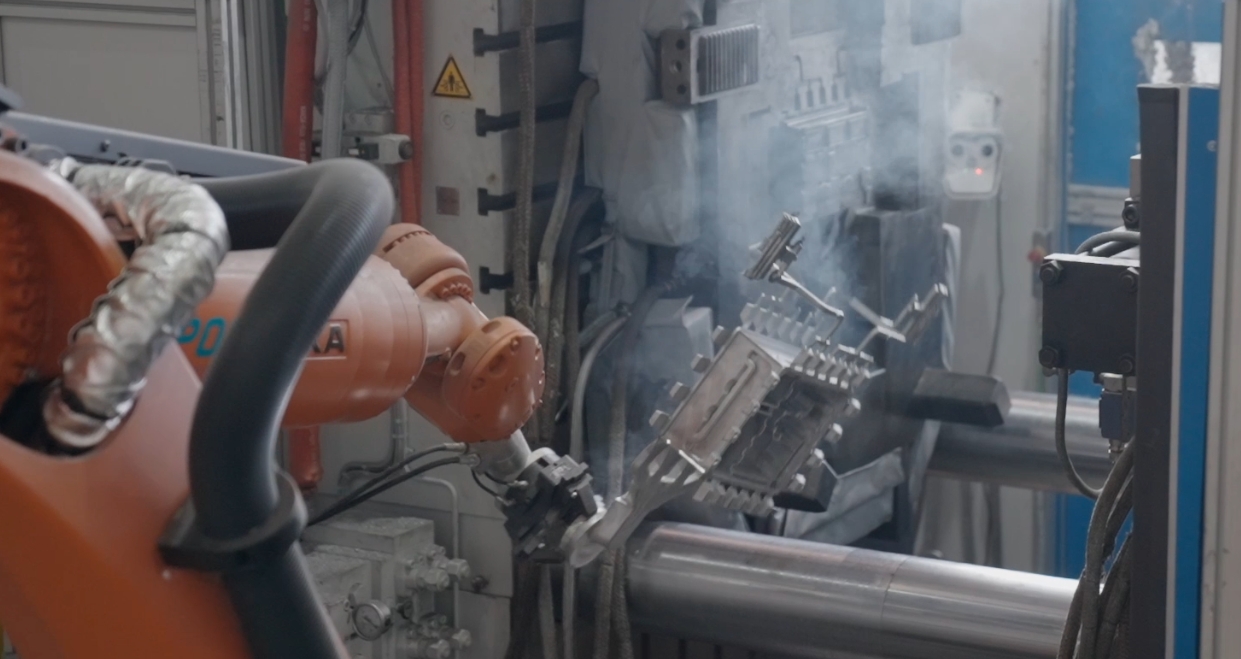

High-pressure die casting is a key process for manufacturing complex aluminum components with stringent requirements for dimensional accuracy and surface quality. Short cycle times and the ability to produce intricate structures in a single casting step make this process indispensable for automotive and aerospace applications. At the same time, high casting speeds and extreme temperature gradients pose significant challenges for process control and tool design.

At LKR, we research and optimize the entire die casting process – from mold filling and solidification to final part quality. Our Frech high-pressure die casting machine enables realistic trials under industrial conditions. In addition, we leverage state-of-the-art simulation methods to gain deeper insights into process physics and develop innovative solutions.

- Simulation as a Key Technology

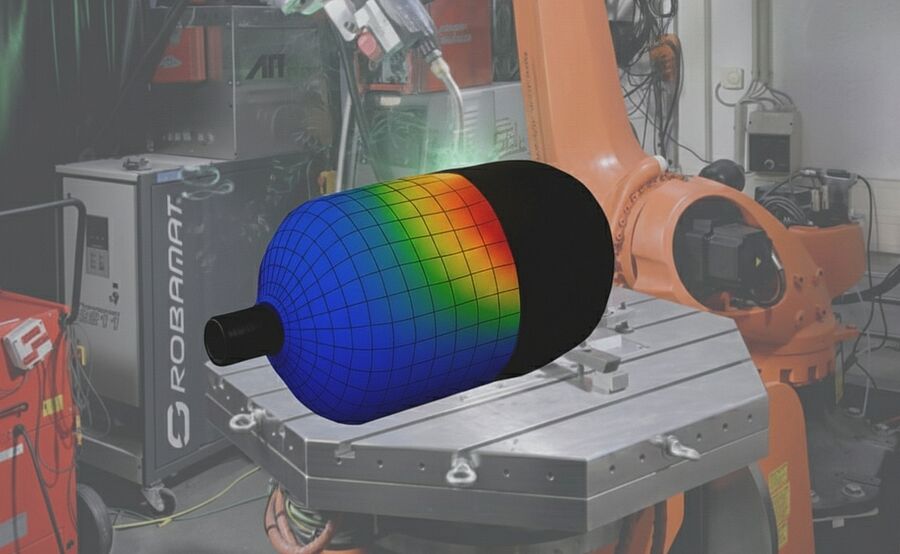

Using spezialized software tools (e.g., NovaCast), we analyze critical process phases such as mold filling, solidification, and porosity formation. This enables us to identify and eliminate potential defects like shrinkage cavities, air entrapment, or hot cracking early in the development phase. - Digital twins for die casting

Our simulation frameworks virtually replicate the entire process, enabling accurate predictions of temperature fields, stresses, and material properties. By combining experimental data with numerical models, we create the foundation for continuous process optimization and quality assurance. - Our service portfolio

In addition to high-pressure die casting, we also offer low-pressure die casting as a technology platform. This allows us to cover a wide range of casting processes and develop the optimal solution for different component requirements.

Discover more about our research projects (metaFacturing, Digi4Circular, EnvioTCast, ECVT, …) and how we combine simulation and experimentation to make casting processes more efficient, robust, and sustainable.

![[Translate to English:] LKR Standort](/fileadmin/_processed_/1/f/csm_AIT_LKR_Standort_4fe61c1df0.jpg)