Die-casting plants on the way to Industry 5.0

Copyright: TCG UNITECH

Digital and green transformation of die-casting plants in Austria

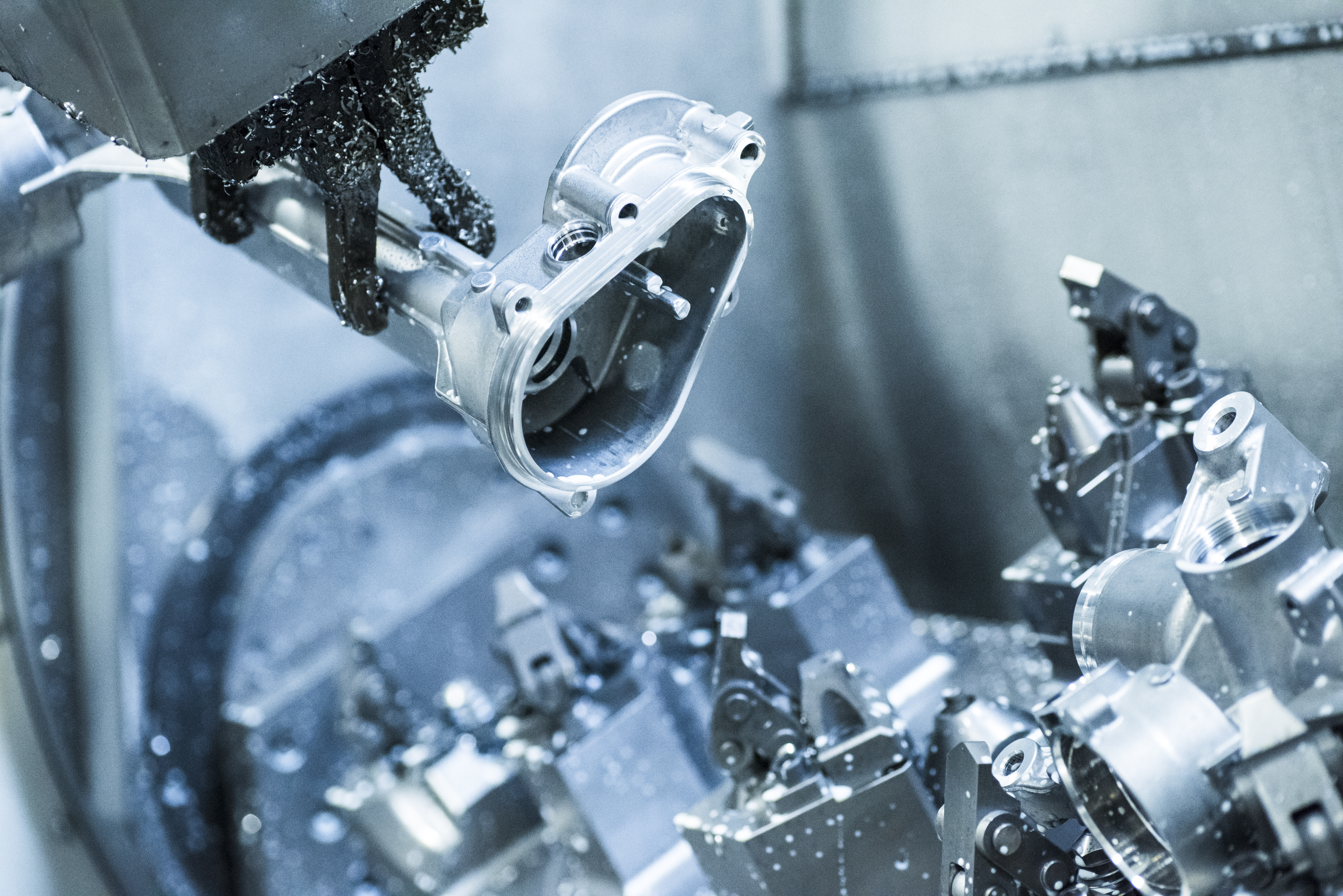

In an effort to reduce the fuel consumption of their vehicles, car manufacturers are increasingly relying on the use of lightweight components made of aluminum or magnesium, especially in the field of electromobility. Austrian foundries play a decisive role in this context, as they have extensive expertise and know-how in the production of high-quality and complex cast components.

Usually, the components are manufactured in a resource-intensive die-casting process. In order to make this process more efficient, the digital and green transformation of Austrian foundries in the sense of Industry 5.0 is to be promoted.

To this end, the recently launched research project DG Assist, led by the AIT Austrian Institute of Technology, is developing an assistance system for the sustainable operation of die-casting plants.

Human-centred assistance systems

In the FFG project DG Assist, partners from research and industry are pooling their expertise. Their goal is to develop an assistance system that ensures agile and sustainable production of high-quality cast components. This should significantly reduce the proportion of defective cast components and thus energy and material consumption.

The experts are relying on the latest information and communication technologies as well as model-based and AI-supported methods. In addition, innovative solutions for human-machine interaction are to be developed to support operators in process monitoring and optimisation as well as quality control.

The assistance system is to be implemented and tested as a prototype on a test machine at the LKR in Ranshofen.

Digital solutions as essential components of the assistance system

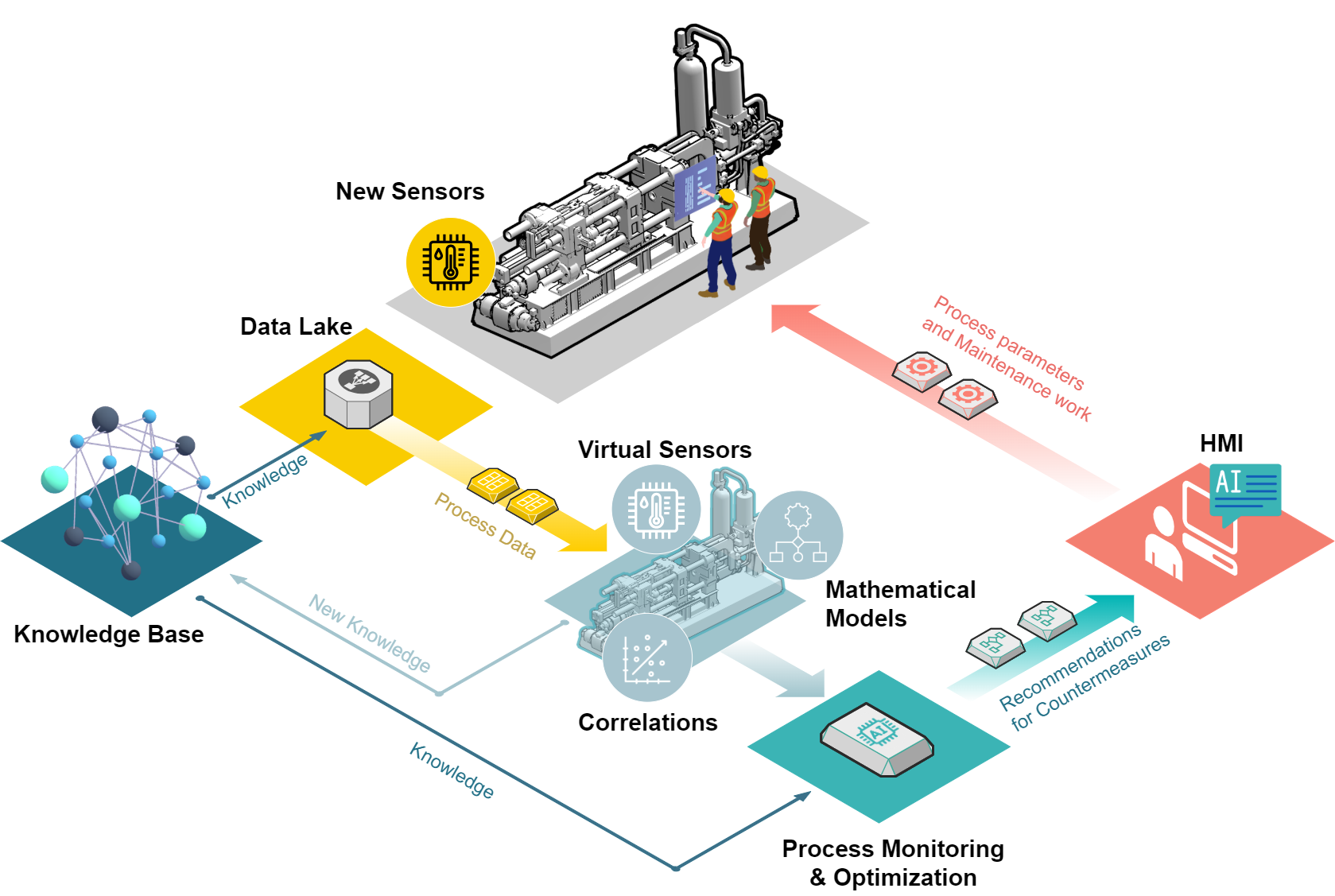

Agile and sustainable production starts with the digitalisation of the plant. To this end, a data and knowledge management system is being developed to facilitate the efficient exchange of data and information between humans, machines, and algorithms.

A knowledge graph is employed to digitally represent process and plant knowledge, facilitating navigation through the heterogeneous data landscape of the die-casting process. This enables more effective monitoring of plant operation and the early detection of excessive energy and material consumption.

Additionally, digital twins of the die casting machine and cast components are being developed to predict the machine's operating status and the quality of the cast components, as well as to identify potential sources of error in good time. Virtual sensors are also being developed to reconstruct previously unmeasurable variables in the die casting process and support the digital twin. This provides operating personnel with additional information for process monitoring.

Ultimately, the information stored in the knowledge graph will be used for knowledge-based machine settings. Thus, the planned assistance system forms the starting point for the development of increasingly efficient production processes and is an essential building block for the targeted use of resources.

Putting human needs at the centre of research

Production operations in foundries largely depend on the expert knowledge and experience of the operating personnel, who carry out tasks such as visual inspection, process monitoring and machine adjustment. Alongside the algorithmic aspects of the assistance system, innovative solutions for human-machine interaction are being developed to meet the needs of operating personnel.

This will not only make workplaces in the harsh environment of a foundry more pleasant, but will also help to counteract the shortage of skilled workers.

Project Facts

Project name

DG Assist - Agile and sustainable production in discontinuous die casting processes through a human-centred assistance system

Duration

01.05.2023 - 30.04.2026

Project partners

AIT Austrian Institute of Technology

LKR Leichtmetallkompetenzzentrum Ranshofen

Maxan Automation

MELTEC Industrieofenbau GmbH

Siemens Aktiengesellschaft Österreich

TCG UNITECH GmbH

Funding

The DG Assist project is funded by the Federal Ministry for Innovation, Mobility and Infrastructure (BMIMI) and carried out as part of the ‘Production and Materials 2022’ call. The Austrian Research Promotion Agency (FFG) has been authorised for the operational management.

https://projekte.ffg.at/projekt/5134166