Aluminium Components for Aviation that are Generatively Manufactured by Means of Laser Beam Welding of Powders

Contrary to rapid prototyping, which mostly results in components with limited functionality, or rapid tooling for the generation of tools, rapid manufacturing will produce components having material properties like serial parts.

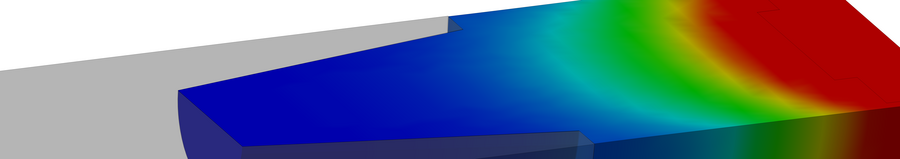

For rapid manufacturing, two different laser processes can be used: Laser cladding and selective laser melting (SLM). In the laser cladding process, the powder gets molten in the laser beam thus resulting in a metallurgical bond to the base material. By adding layer after layer, 3D-components can be produced. With the newer SLM technique the component is generated directly out of a powder bed.

Through this project the possibilities for aluminium parts generated by these two laser techniques shall be explored.

Project Partners

- LKR Leichtmetallkompetenzzentrum Ranshofen GmbH

- FOTEC Forschungs- und Technologietransfer

- TEST-FUCHS

- JOANNEUM RESEARCH

- Schild & Partner

- Mepura Metallpulvergesellschaft Ranshofen

Project duration: 2014-2017