For 30 years, EUROGUSS in Nuremberg has been bringing together experts from the die casting sector from all over the world. Since its inception, EUROGUSS has established itself as an indispensable platform for the entire die casting industry. Over 14,000 visitors attended the last EUROGUSS in 2024 – and this year's fair is even bigger: at EUROGUSS 2026, 600 companies will be showcasing their services and products in six exhibition halls for the first time.

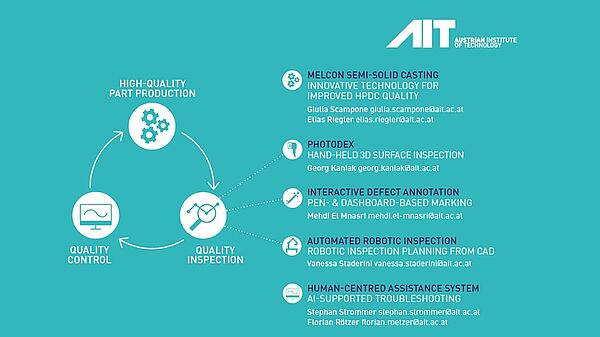

Hall 5 is dedicated to research, and AIT will be there with a stand. Take this opportunity to discover exciting innovations first-hand, talk to experienced AIT experts and gain insights into the trends that are having a lasting impact on the value creation process. At EUROGUSS, AIT will be presenting integrated solutions along the entire value chain

• High-quality production technologies for components such as MELcon semi-solid casting enable a significant reduction in porosity and oxide inclusions as well as extended tool life – with minimal intervention in existing HPDC systems.

• Quality inspection solutions ranging from hand-held 3D surface inspection (PHOTODEX) and interactive defect annotation to automated robotic inspection planning based on CAD data enable both complete component capture and targeted, cycle time-optimised inspections.

• Quality control and human-centred AI-supported assistance systems support operators in root cause analysis, decision-making and process optimisation, thereby contributing to the reduction of scrap, downtime and material and energy consumption.

Interdisciplinary expertise, holistic approach

Several AIT centers are pooling their complementary expertise to develop a holistic approach for the die casting and light metal industry – from component manufacturing, inspection and quality control to user-centred assistance and interactive defect annotation in the production environment.

The AIT Center for Vision, Automation & Control develops solutions in the fields of image processing, automation, control engineering and artificial intelligence to digitise production and inspection processes throughout. The aim is to make industrial systems more flexible, adaptive and resilient while increasing quality, energy and resource efficiency, and cost-effectiveness.

The Light Metal Competence Center in Ranshofen complements these competencies as a leading research institution for light metals and lightweight construction. With decades of experience, the LKR covers the entire value chain – from innovative alloys and energy-efficient casting and forming processes to functionally integrated lightweight components and recycling solutions. The technologies developed are widely used, particularly in the automotive sector and in aerospace.

The AIT Center for Technology Experience focuses on the interaction and interplay between humans and technology and supports industry partners in designing an intuitive, accepted and efficient user experience. User experience research and experience-driven innovation are key success factors for sustainable industrial technologies – also subsumed under the buzzword Industry 5.0 (digital, human-centred, sustainable).

5 stations at the AIT booth

- High-quality Part production technologies: MELcon Semi-Solid Casting

- Hand-held 3D surface inspection: PHOTODEX

- Interactive defect annotation

- Automated robotic inspection

- Human-centred assistance system

The AIT team at EUROGUSS

Giulia Scampone, Elias Riegler, Georg Kaniak, Mehdi El-Mnasri, Vanessa Staderini, Stephan Strommer, Florian Rötzer, David Gruber and Iman Kulitz.

AIT presentation on 15 January 2026

Human-centered AI-supported assistance system for agile and sustainable production in the discontinuous die casting process

DI Dr Stephan Strommer, AIT Center for Vision, Automation & Control

WHEN: Thursday, 15 January 2026, 1 p.m. to 1.30 p.m.

WHERE: Speakers Corner, Hall 4, Stand 4-468

AIT at EUROGUSS: Hall 5, Booth 5-338

13 to 15 January 2026, daily from 9 a.m. to 5 p.m.

AIT Austrian Institute Of Technology Gmbh

Information Material

ZERO DEFECT DIGITAL MANUFACTURING

Research & solutions for smart productions of the future (Flyer, English)

PHOTODEX

High-resolution 3D scanning of defects (Flyer, English)