Novel processing methods for magnesium forming

The continuously increasing mobility of people and goods results in steadily growing energy consumption and CO2 emissions. In Europe, the mobility sector is responsible for almost 30% of total final energy consumption, making it the largest single energy consumer. The goal set by the European Union of complete climate neutrality by 2050 and the currently prevailing dependence on non-European raw material and technology suppliers require the creation of new solutions.

Material-based lightweight construction using magnesium offers significant potential for energy savings in operational use. Magnesium (Mg) can be obtained relatively cleanly and energy-efficiently from raw materials that are readily available worldwide using state-of-the-art technologies, and its low density and high specific strength offer strong lightweight design potential. However, material-based lightweight construction with magnesium is almost always associated with higher costs compared to heavier metals for structural applications (e.g. steel, but also aluminum).

While cast components made from Mg are now state of the art, formed products made from Mg alloys still represent a niche application. Rolled and extruded products (sheets, tubes, profiles) have become an indispensable part of modern lightweight construction and offer great potential for Mg alloys. However, especially in this area, Mg has significant disadvantages due to its inherently poor formability, the limited choice of alloys and the lack of process know-how, as a result of which it has not yet been possible to use it on a large scale.

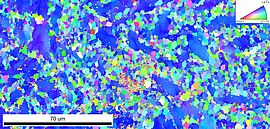

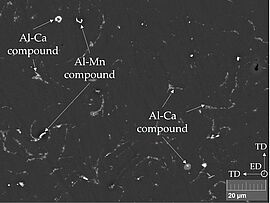

By using Ca-containing Mg alloys in formed products, these issues can be successfully addressed, and a group of materials can be created that meets the numerous challenges posed to a modern, climate-friendly material.

However, the disadvantage of this system is that little process knowledge is available and applicable process parameters are lacking. While these materials have not yet reached the processing industry, scientific considerations are limited to processing temperatures of 350°C and below. The low forming temperature results in poor formability and thus high process costs, making the material less attractive. The "Pro-Imagine" project has therefore set itself the goal of extending the process window for Ca-containing Mg alloys to higher temperatures through material selection and suitable process control. This should increase industrial acceptance for the material and accelerate its industrial application, while at the same time achieving significant energy savings.

Funded by the Federal Ministry for Climate Protection, Environment, Energy, Mobility, Innovation and Technology (BMK) and the Austrian Research Promotion Agency (FFG) as part of Mobility of the Future - Sustainable Vehicle Technologies.