Process-related aluminum casting alloy development in horizontal continuous casting

Today, aluminum alloys are increasingly used in mobility applications due to their low density and good property profile. Whenever customers have to change processes (due to an increase in production capacity, cost reduction or reduction in process steps), the quality and costs of the end application must be assessed in advance and the manufacturing and product development cycles must be kept as short as possible. On the one hand, to save development costs, and on the other hand, to achieve maximum flexibility in the ever faster changing markets and to manufacture profitably even in smaller quantities.

Horizontal continuous casting plant with melting furnace

These customer requirements, which sometimes demand top-quality castings of special aluminum alloys in very small (1-15 tons per year) or small quantities (15-400 tons per year), are contrasted by usual large-scale industrial casting tonnages of over 100 tons per casting; 100 tons is the usual capacity of a large-scale industrial melting furnace. In order to close this gap between supply and demand, the experts at the LKR Light Metal Competence Center Ranshofen have joined forces with a nearby industrial partner specializing in small batches to create a unique offering:

The objective is to investigate the different influences of essential casting parameters such as cooling water, grain refiner additions, mold type - influence of dual cooling (primary and secondary cooling) - , casting temperature and casting speed by coupling thermodynamic simulations with experimental investigations and to quantitatively determine their effect on microstructure, homogeneity and surface quality. This enables the specification of critical limit values and the associated process-related prediction of the expected material qualities.

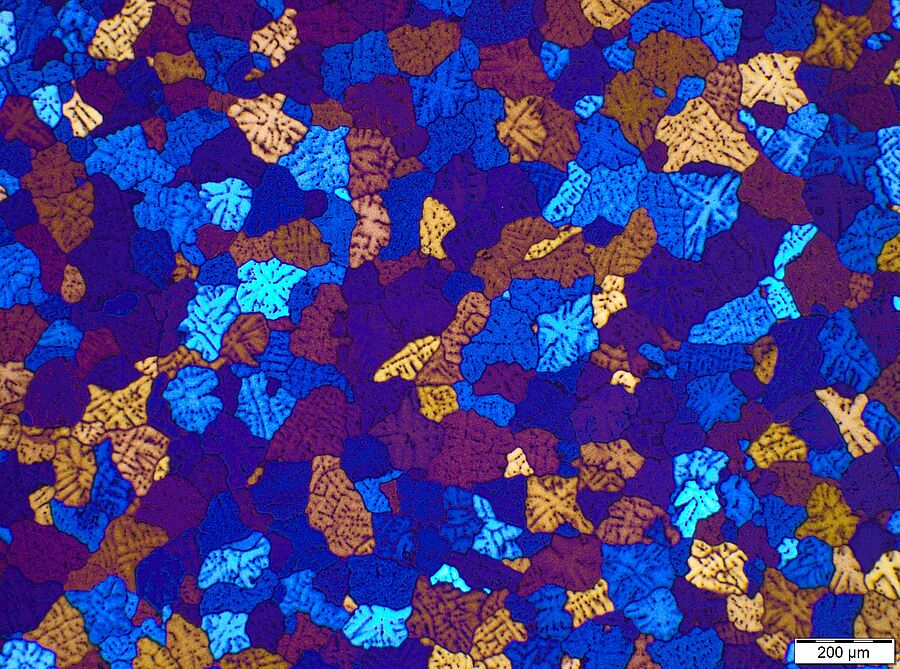

Cast strand

In addition, the LKR has the possibility to provide plant capacities for tests (see images) and to conduct training courses for employees. This makes it possible to subsequently define casting recipes taking into account the desired microstructural characteristics (e.g. distribution and size of the precipitates by optimizing the chemical composition). This enables efficient and cost-effective technology transfer to serial application.

In horizontal continuous casting (HSG), LKR can produce from a few 100 to 1.800 kilograms per casting. Thus LKR can produce, with its semi-industrial plant, beyond the alloy and process development just described, even very small batches. Small batches of 15-400 tons per year can be produced at the cooperation and development partner HPI. LKR has extensive experience in know-how transfer and is driving development forward hand in hand with its colleagues.

The advantages of process-related aluminum casting alloy development at LKR summarized:

- Complete infrastructure for advanced casting tests / method development / optimizations.

- Many years of experience in casting non-standard aluminum alloys

- Full characterization capabilities in-house (test lab-metallography-REM-DSC, ...)

- IBA data recording system for optimal monitoring of casting parameters

In addition, a comparable mapping of the process route in the field of vertical continuous casting can be offered. For more detailed information on key technical data as well as available casting geometries, please visit our website:

![[Translate to English:] LKR Standort](/fileadmin/_processed_/2/8/csm_AIT_LKR_Standort_4fe61c1df0.jpg)