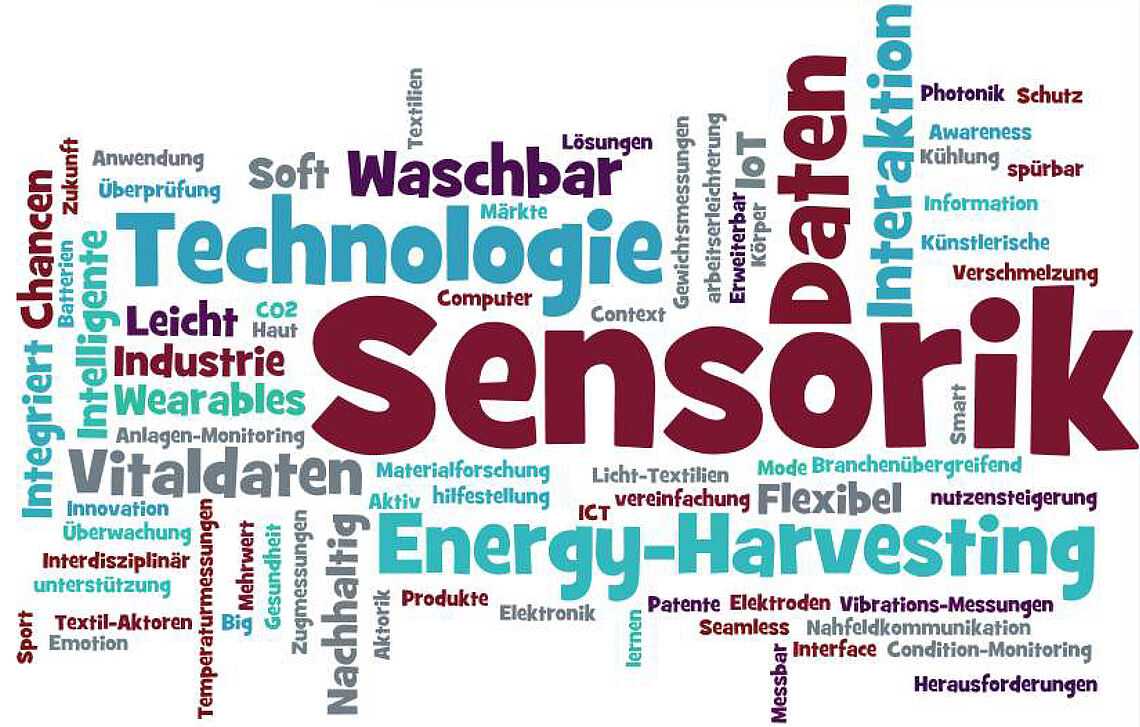

A time-honored industry that has slipped into crisis in recent decades could gain renewed momentum thanks to new technologies: Smart sportswear, innovative medical products or intelligent jackets will soon be highly sought-after products. This will require know-how from many different areas to be brought together.